|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back

to Product Category

YK™

ELECTRIC WIRE ROPE HOISTS

AND CRANE COMPONENTS |

|

When you need

quality and performance in a wire rope hoist, turn to the YK™ hoist.

Based on German

technology, the YK delivers the industry-leading technology and safety you

need for your lifting applications

in a compact, easy-to-maintain design. Precision engineered, these hoists

are built for reliable operation, high

efficiency, and long service life and are competitively priced for the U.S.

market. Operators, crane manufacturers,

and system manufacturers can benefit from the hoist's modular system that

allows for configuration of the hoist

and crane system to exact application needs. Complete with a low-headroom

trolley, the YK is ideal for applications

with space limitations. |

|

|

|

|

|

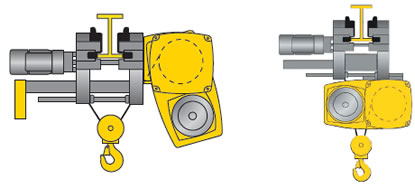

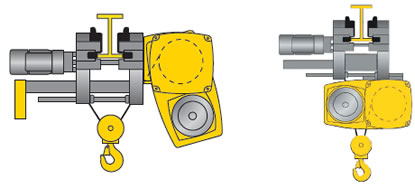

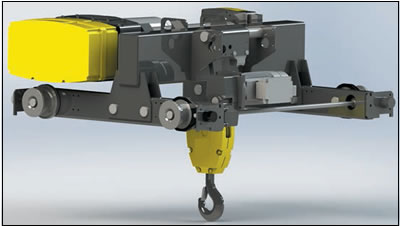

LOW-HEADROOM

MONORAIL TROLLEY |

STANDARD

HEADROOM

MONORAIL TROLLEY |

|

The monorail

trolley is used on

monorail runways and single-

girder overhead traveling cranes.

Trolley is easily adjustable for

different beam sizes and comes

standard with two speed trolley.

Available for 1-15 ton capacities. |

Specially

designed for small

clearances, the monorail trolley

has a narrow width. It is used on

monorail runways and single-girder

overhead traveling cranes.

Available for 20-30 ton capacities. |

| LIFT:

MAXIMUM 66 FT. |

|

|

|

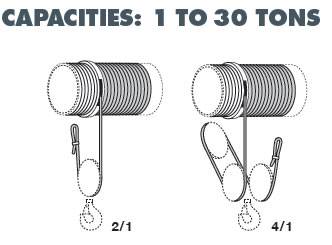

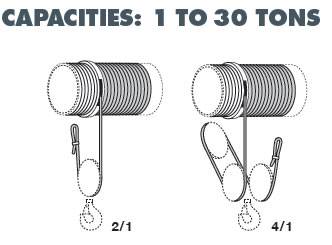

| SINGLE-GROOVED

ROPE DRUM |

|

2-part

single or 4-part single reeving is available,

depending on the application. |

|

|

|

|

|

|

|

|

|

|

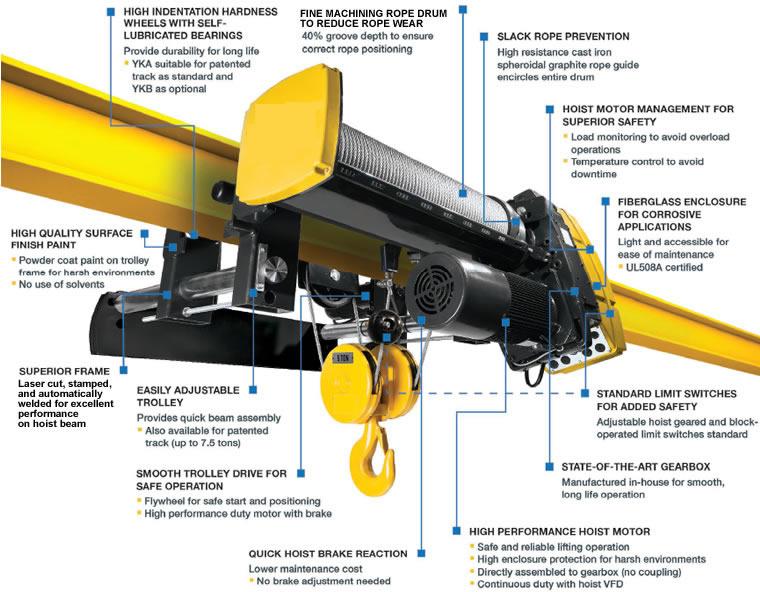

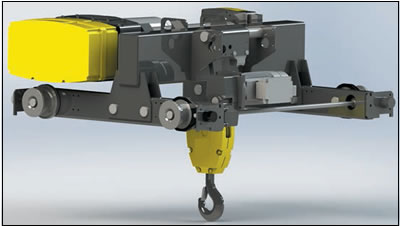

COMPACT DESIGN

Compact dimensions due to U-shape design.

Exceptionally short approach allows for

optimum use of work area when space is limited. |

|

|

|

|

|

LOW MAINTENANCE

Largely maintenance-free design with field-proven

components designed for low wear and long service

life. |

|

|

|

|

|

SHORT LEAD TIMES

Assembled in Wadesboro, North Carolina, with

German-made components, these units offer short

lead times to meet tight deadlines. |

|

|

|

|

OPTIONAL PANEL

AND MOTOR HEATERS

Available for hoist, trolley, and bridge motions. |

|

|

|

|

|

|

|

H3, H4 & H4+ DUTY CYCLE |

|

|

|

|

|

|

|

FLEXIBLE CONFIGURATIONS

Hoists can be configured to your unique application

needs. Available in 5 frame sizes with 16 load capacity

variants. |

|

|

|

|

OPTIONAL PATENTED

TRACK WHEELS

Monorail trolley packages for patented track wheels

are available for capacities up to 7.5 tons. |

|

|

|

|

|

|

|

OPTIONAL TRAVEL

LIMIT SWITCH

Standard version includes limit switching in both

directions, switching from fast/slow, and IP65 or

NEMA 4/4X rating. Wired and mounted to the hoist. |

|

|

|

|

|

|

EXTENSIVE

SAFETY FEATURES

Standard safety features include block-operated limit

switch, adjustable geared limit switch, motor temperature

control, and overload protection. |

|

|

|

OPTIONAL TOWING

ARM

Available for power supply with adjustable

height and length. |

|

|

|

|

|

|

SMOOTH OPERATION

Extremely smooth starting and braking characteristics. |

|

|

|

|

|

|

|

|

|

| OPTIONAL PENDANT

CONTROL |

|

|

|

|

|

|

|

|

|

| OPTIONAL SPARE

PARTS KIT |

|

|

|

|

|

STANDARD

FEATURES |

|

| Features |

Capacities: 1–30 tons

Lift Heights: Up to 66 feet

Ambient Temperature: -4°F to +104°F (-20°C to +40°C)

Hoist & Trolley Protection to IEC/EN 60529: IP55 or NEMA 4/12

Voltage: 208, 230, 460V, 3 phase, 60 Hz (Control Voltage 120V)

Third Party Labeling: UL508A

Warranty: 3-year standard |

| Hoist |

Reeving: 2PS & 4PS

Hoist Speed Control: 2-speed control. Optional Magnetek VFD

Complete Hoist Control: Includes mainline contactor K10, transformer

& trolley fuses.

Does not include: main hoist fuses to be sized for both hoist and trolley

– for use on monorails

Crane MFG Control: Includes safety contactor K20, trolley fuses.

Hoist control does not

include: transformer, mainline, main fuses sized for hoist & trolley

(items not included to be

located in bridge control panel) – for use on cranes

Control Enclosure: Fiberglass – IP55 or NEMA 4/12

Overload Protection: Standard electronic load limiting device

Geared Limit Switch: Four switching points (3 up, 1 down), Emergency

top, Operational

top, Changeover from fast to slow, Emergency bottom

Block-Operated Limit Switch: Standard

Rope Guide: Cast iron spheroidal graphite

Hoist Motor:

Standard hoist performance monitoring

3 phase A.C. squirrel cage induction motor, 2-speed cylindrical

motor and flywheel mass for smooth start and stop

6:1 ratio with class F insulation, S4 duty class, 40/20% duty cycle

IP55 or NEMA 4/12

Standard motor thermal protection

Hoist motor connection wired into control enclosure

Hoist Motor Brake:

DC power, no adjustment needed

IP66 or NEMA 4/4x

Double-sided, asbestos-free linings on monodisc

Hoist Drum: Machined steel – 40% grooved depth

Hoist Gearing: Helical lubed for life

Bearings: Anti-friction. All sealed for life

Hook Assembly: 360° rotation with safety latch

Paint Two part polyurethane base and top coat to 3.2 mil thickness

or

epoxy powder coat to 2.4 mil, Yale yellow |

|

| Trolley |

Types: Monorail

Trolley Control: Magnetic contactor – 2 speed. Optional Magnetek

VFD

Travel Motor Speed 60 Hz: 80/20 fpm

Bumpers & Drop Lugs: Standard

Mechanical Safety Devices: All trolleys come standard with anti-tipping

devices and trolley guards

Trolley Motor: 2 speed, S4 duty class, class F insulation, IP55 or NEMA

4/12

Trolley Brake: DC brake

Trolley Gearing: Helical

Temperature Control of Travel Motors: Standard

Wheel Material: Ductile Iron 240 BHN |

|

|

|

|

|

|

|

BUILT

TO PERFORM |

|

|

|

|

TECHNOLOGY |

|

|

|

|

|

You can work with

confidence knowing the

technology behind the YK is built to the

highest industry standards. Working together,

these low-maintenance components provide

best-in-class performance, high efficiency,

and long service life for any application. The

YK is also designed with safety in mind,

including features such as geared limit switches,

motor temperature control, and overload

protection. |

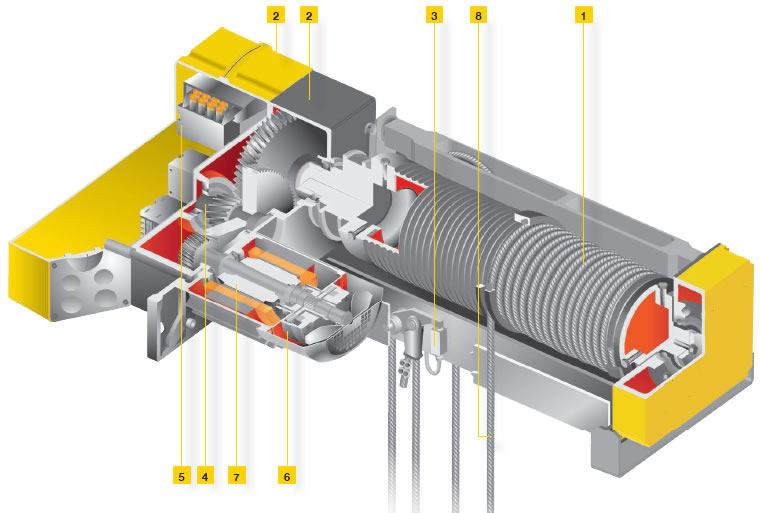

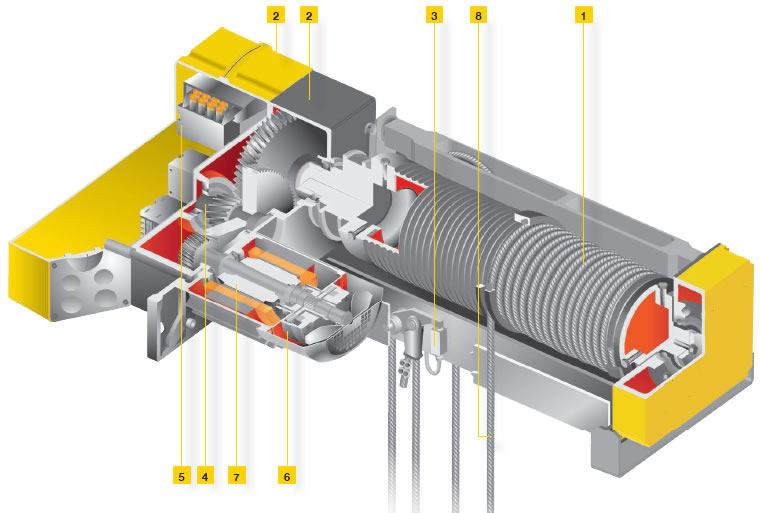

1.

ROPE AND ROPE GUIDE |

2. PAINT |

|

|

|

|

•

Specialized wire rope is highly

flexible and features a long service

life

• Field-proven enclosed rope guide

constructed of spheroidal graphite

cast iron for high-temperature

environments

• GJS material (previously designated

GGG40) is suitable for extreme high

and low temperatures

• 360° rope tensioner prevents rope

slackening for added safety and

performance

• Prevents overwrap and slack rope |

• Standard paint treatment

in

yellow

• High-quality

primer and top

coats also available as

standard |

|

|

|

|

|

|

|

|

|

|

|

|

| 3.

OVERLOAD PROTECTION |

|

4. PRECISION GEARING |

|

5.

CONTROL PANEL |

|

|

|

|

|

|

• Continuous electronic

load monitoring

when load is suspended

• Limitation

on maximum load determined

by load measurement at the rope

anchorage point |

|

• Lifetime oil-lubricated

gearbox means

no oil change out is required

• Precision gearing for quiet operation

• Enclosed housing for maximum

accuracy and stability |

|

•

Standard motor performance monitoring

• Inching operation is suppressed for

reduced jogging

• Oversized contactors for added safety

• Standard temperature monitoring of

hoist and travel motors

• UL508A control enclosure for hoist,

trolley, and bridge motions |

|

|

|

|

|

|

|

|

|

|

|

| 6.

BRAKE |

|

7. MOTOR |

|

8. BOTTOM BLOCK |

|

|

|

|

|

•

Low-maintenance, asbestos-free

brake needs no adjustment

• Oversized, heavy-duty brake for long

service life

• Brake is easily accessible from the

outside for ease of maintenance and

inspection

• Motor management ensures low wear

• IP66 or NEMA 4/4x protection |

|

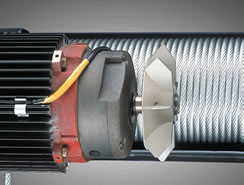

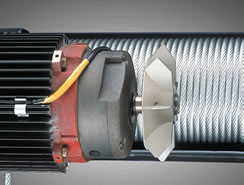

•

Specially designed motor specific to

hoisting applications with high

operational demands

• Classified according to FEM (ISO)

with high duty cycle and switching

operation frequency

• IP55 or NEMA 4/12, thermal class F

• Motor outside rope drum ensures

highly efficient motor cooling and

is easy to maintain

• PTC thermistors ensure reliable

temperature control for slow or fast

speeds

• Reliable operation, even with low

voltage or heavy loads |

|

•

Optimal drum-to-sheave diameter ratio

for reduced rope wear

• Wire rope is flexible and durable for

long life

• Fine machining of drum reduces wear

on rope and sheaves

• Drum is easily accessible for rope

maintenance or replacement

• Robust bottom hook block with low

headroom design for use in tight spaces |

|

|

|

|

|

|

|

|

QUICK

SHIP PROGRAM PRICING |

|

YK monorail hoists

and crane kits are available as Quick Ship units designed to ship in as

little as 48 hours.

The Quick Ship Program has proven to be the reliable and trusted solution

when fast delivery is critical.

One catalog, one shipment, one warehouse with world class delivery - ordering

doesn't get any easier. |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

HOIST

& MONORAIL TROLLEY |

Model

No. |

Hoist |

Trolley |

Hoist

Control |

Other

Data |

Price |

Cap.

(ton) |

Reeving |

Lift

(ft) |

Lift

speed

(fpm) |

Nominal

Motor

HP |

Rating |

Trolley

Speed

(fpm) |

Motor

HP |

Wheel

Dia.

(in) |

Beam

flange

range

(in) |

Power

Supply |

Control

Volt |

Wgt. |

C45585711YK |

5 |

4

PS |

33 |

20/3.3 |

7.8/1.3 |

H4 |

80/20 |

0.6/0.15 |

4 |

8 |

12 |

Complete

Hoist |

460-3-60 |

120V |

787 |

|

C45585712YK |

5 |

4

PS |

33 |

20/3.3 |

7.8/1.3 |

H4 |

80/20 |

0.6/0.15 |

4 |

8 |

12 |

Crane

MFG |

460-3-60 |

120V |

787 |

|

C45585811YK |

10 |

4

PS |

33 |

20/3.3 |

14.8/2.1 |

H4 |

80/20 |

0.9/0.2 |

5

1/2 |

8 |

12 |

Complete

Hoist |

460-3-60 |

120V |

1753 |

|

C45585812YK |

10 |

4

PS |

33 |

20/3.3 |

14.8/2.1 |

H4 |

80/20 |

0.9/0.2 |

5

1/2 |

8 |

12 |

Crane

MFG |

460-3-60 |

120V |

1753 |

|

|

|

|

|

| IMPORTANT:

When ordering. |

|

Step

1: Pick a Model Number

Just a single model number for a standard

unit with complete hoist controls or a crane MFG controls |

|

|

|

|

| NOTE: |

|

|

Pushbutton

stations are not included in Base Hoist Price

Please go to options. |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

2

PART REEVED MONORAIL HOIST & TROLLEY PRICING |

Model

No. |

Hoist |

Trolley |

Headroom

(in)* |

Net

Wgt. |

Price |

Cap.

(ton) |

Reeving |

Lift

(ft) |

Lift

speed

(fpm) |

Nominal

Motor

HP

| Rating |

Trolley

Speed

(fpm) |

Motor

HP |

Wheel

Dia.

(in) |

Beam

flange

range (in)† |

|

1 |

2

PS |

39 |

39/6.6 |

5.8

/ 0.9

| H4+ |

80/20 |

0.6/0.15

| 3

1/8 |

3

1/4 |

19

3/4 |

28

3/8 |

584 |

|

|

1 |

2

PS |

66 |

39/6.6 |

5.8

/ 0.9

| H4+ |

0.6/0.15

| 3

1/8 |

3

1/4 |

19

3/4 |

28

3/8 |

617 |

|

|

2 |

2

PS |

40 |

31/5.2 |

7.8/1.3

| H4 |

80/20 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

30

7/8 |

672 |

|

|

2 |

2

PS |

66 |

31/5.2 |

7.8/1.3

| H4 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

30

7/8 |

732 |

|

|

2.75 |

2

PS |

40 |

39/6.6 |

7.8/1.3

| H4 |

80/20 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

30

7/8 |

672 |

|

|

2.75 |

2

PS |

66 |

39/6.6 |

7.8/1.3

| H4 |

0.6/0.1

| 4 |

3

5/8 |

19

3/4 |

30

7/8 |

732 |

|

|

2.75 |

2

PS |

131 |

39/6.6 |

7.8/1.3

| H4 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

35 |

866 |

|

|

3 |

2

PS |

40 |

31/5.2 |

7.8/1.3

| H4 |

80/20 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

30

7/8 |

672 |

|

|

3 |

2

PS |

66 |

31/5.2 |

7.8/1.3

| H4 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

30

7/8 |

732 |

|

|

3 |

2

PS |

40 |

39/6.6 |

14.8/2.1

| H4+ |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

34 |

1620 |

|

|

3 |

2

PS |

66 |

39/6.6 |

14.8/2.1

| H4+ |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

34 |

1709 |

|

|

3 |

2

PS |

131 |

39/6.6 |

14.8/2.1

| H4+ |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

44

5/8 |

2181 |

|

|

4 |

2

PS |

40 |

39/6.6 |

14.8/2.1

| H4 |

80/20 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

34 |

1620 |

|

|

4 |

2

PS |

66 |

39/6.6 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

34 |

1709 |

|

|

4 |

2

PS |

131 |

39/6.6 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

44

5/8 |

2182 |

|

|

5 |

2

PS |

40 |

39/6.6 |

14.8/2.1

| H4 |

80/20 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

34 |

1620 |

|

|

5 |

2

PS |

66 |

39/6.6 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

34 |

1709 |

|

|

5 |

2

PS |

131 |

39/6.6 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

44

5/8 |

2182 |

|

|

6 |

2

PS |

40 |

25/3.9 |

14.8/2.1

| H4 |

80/20 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

35

7/8 |

1988 |

|

|

6 |

2

PS |

66 |

25/3.9 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

35

7/8 |

2027 |

|

|

7.5 |

2

PS |

40 |

25/3.9 |

14.8/2.1

| H4 |

80/20 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

35

7/8 |

1988 |

|

|

7.5 |

2

PS |

66 |

25/3.9 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

35

7/8 |

2027 |

|

|

7.5 |

2

PS |

56 |

25/3.9 |

14.8/2.1

| H4 |

80/20 |

0.6/0.15

| 7

7/8 |

4

7/8 |

19

3/4 |

41

1/2 |

2954 |

|

|

7.5 |

2

PS |

93 |

25/3.9 |

14.8/2.1

| H4 |

0.6/0.15

| 7

7/8 |

4

7/8 |

19

3/4 |

57

1/2 |

3307 |

|

|

| Click

model number for detailed drawing |

|

| (*) Headroom

values may vary depending on trolley flange adjustment |

†

Give proper beam flange width when ordering, no extra charge. See standard

flange range table below.

Note: UL508A Labeled Controls is standard for all models |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

4

PART REEVED MONORAIL HOIST & TROLLEY PRICING |

Model

No. |

Hoist |

Trolley |

Headroom

(in)* |

Net

Wgt. |

Price |

Cap.

(ton) |

Reeving |

Lift

(ft) |

Lift

speed

(fpm |

Nominal

Motor HP

| Rating |

Trolley

Speed

(fpm) |

Motor

HP |

Wheel

Dia.

(in) |

Beam

flange

range (in) |

|

2 |

4

PS |

20 |

20/3.3 |

5.8/0.9

| H4+ |

80/20 |

0.6/0.15

| 3

1/8 |

3

1/4 |

19

3/4 |

22

1/2 |

617 |

|

|

2 |

4

PS |

33 |

20/3.3 |

5.8/0.9

| H4+ |

0.6/0.15

| 3

1/8 |

3

1/4 |

19

3/4 |

22

1/2 |

650 |

|

YKA-LD3-020S420-2 |

2.5 |

4

PS |

20 |

20/3.3 |

5.8/0.9

| H4 |

80/20 |

0.6/0.15

| 3

1/8 |

3

1/4 |

19

3/4 |

22

1/2 |

617 |

|

YKA-LD3-033S420-2 |

2.5 |

4

PS |

33 |

20/3.3 |

5.8/0.9

| H4 |

0.6/0.15

| 3

1/8 |

3

1/4 |

19

3/4 |

22

1/2 |

650 |

|

|

3 |

4

PS |

20 |

20/3.3 |

5.8/0.9

| H4 |

80/20 |

0.6/0.15

| 3

1/8 |

3

1/4 |

19

3/4 |

22

1/2 |

617 |

|

|

3 |

4

PS |

33 |

20/3.3 |

5.8/0.9

| H4 |

0.6/0.15

| 3

1/8 |

3

1/4 |

19

3/4 |

22

1/2 |

650 |

|

|

4 |

4

PS |

20 |

20/3.3 |

7.8/1.3

| H4 |

80/20 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

26

5/8 |

728 |

|

|

4 |

4

PS |

33 |

20/3.3 |

7.8/1.3

| H4 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

26

5/8 |

787 |

|

|

4 |

4

PS |

66 |

20/3.3 |

7.8/1.3

| H4 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

26

5/8 |

921 |

|

|

5 |

4

PS |

20 |

20/3.3 |

7.8/1.3

| H4 |

80/20 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

26

5/8 |

728 |

|

|

5 |

4

PS |

33 |

20/3.3 |

7.8/1.3

| H4 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

26

5/8 |

787 |

|

|

5 |

4

PS |

66 |

20/3.3 |

7.8/1.3

| H4 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

26

5/8 |

866 |

|

|

6 |

4

PS |

20 |

16/2.6 |

7.8/1.3

| H4 |

80/20 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

26

5/8 |

728 |

|

|

6 |

4

PS |

33 |

16/2.6 |

7.8/1.3

| H4 |

0.6/0.15

| 4 |

3

5/8 |

19

3/4 |

26

5/8 |

787 |

|

|

7.5 |

4

PS |

20 |

16/2.6 |

7.8/1.3

| H4 |

80/20 |

0.9/0.2

| 4 |

3

5/8 |

19

3/4 |

26

4/7 |

728 |

|

|

7.5 |

4

PS |

33 |

16/2.6 |

7.8/1.3

| H4 |

0.9/0.2

| 4 |

3

5/8 |

19

3/4 |

26

4/7 |

787 |

|

|

7.5 |

4

PS |

20 |

20/3.3 |

14.8/2.1

| H4+ |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

32 |

1664 |

|

|

7.5 |

4

PS |

33 |

20/3.3 |

14.8/2.1

| H4+ |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

32

1/8 |

1753 |

|

|

7.5 |

4

PS |

66 |

20/3.3 |

14.8/2.1

| H4+ |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

32

1/8 |

2116 |

|

|

9 |

4

PS |

20 |

20/3.3 |

14.8/2.1

| H4 |

80/20 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

32 |

1664 |

|

|

9 |

4

PS |

33 |

20/3.3 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

32 |

1753 |

|

|

9 |

4

PS |

66 |

20/3.3 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

32 |

2116 |

|

|

10 |

4

PS |

20 |

20/3.3 |

14.8/2.1

| H4 |

80/20 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

32 |

1664 |

|

|

10 |

4

PS |

33 |

20/3.3 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

32 |

1753 |

|

|

10 |

4

PS |

66 |

20/3.3 |

14.8/2.1

| H4 |

0.9/0.2

| 5

1/2 |

4

5/8 |

19

3/4 |

32 |

2116 |

|

YKC-L12-020S413-2 |

12.5 |

4

PS |

20 |

13/2.0 |

14.8/2.1

| H4 |

80/20 |

2.0/0.5

| 5

1/2 |

4

5/8 |

19

3/4 |

33

1/4 |

1764 |

|

YKC-L12-033S413-2 |

12.5 |

4

PS |

33 |

13/2.0 |

14.8/2.1

| H4 |

2.0/0.5

| 5

1/2 |

4

5/8 |

19

3/4 |

33

1/4 |

1852 |

|

YKC-L15-020S413-2 |

15 |

4

PS |

20 |

13/2.0 |

14.8/2.1

| H4 |

80/20 |

2.0/0.5

| 5

1/2 |

4

5/8 |

19

3/4 |

33

1/4 |

1764 |

|

YKC-L15-033S413-2 |

15 |

4

PS |

33 |

13/2.0 |

14.8/2.1

| H4 |

2.0/0.5

| 5

1/2 |

4

5/8 |

19

3/4 |

33

1/4 |

1852 |

|

|

15 |

4

PS |

20 |

25/3.9 |

26.8/4.5

| H3 |

2.0/0.5

| 5

1/2 |

4

5/8 |

19

3/4 |

33

1/4 |

1922 |

|

|

15 |

4

PS |

33 |

25/3.9 |

26.8/4.5

| H3 |

2.0/0.5

| 5

1/2 |

4

5/8 |

19

3/4 |

33

1/4 |

2024 |

|

|

15 |

4

PS |

28 |

20/3.3 |

26.8/4.5

| H4 |

2.0/0.5

| 7

7/8 |

4

7/8 |

19

3/4 |

39

1/8 |

3131 |

|

|

15 |

4

PS |

46 |

20/3.3 |

26.8/4.5

| H4 |

2.0/0.5

| 7

7/8 |

4

7/8 |

19

3/4 |

39

1/8 |

3483 |

|

|

15 |

4

PS |

93 |

20/3.3 |

26.8/4.5

| H4 |

2.0/0.5

| 7

7/8 |

4

7/8 |

19

3/4 |

39

1/8 |

4034 |

|

|

20 |

4

PS |

20 |

16/2.6 |

26.8/4.5

| H4 |

80/20 |

2x

0.9/0.2 |

7

7/8 |

7

1/4 |

19

5/8 |

63

3/4 |

5302 |

|

|

20 |

4

PS |

33 |

16/2.6 |

26.8/4.5

| H4 |

2x

0.9/0.2 |

7

7/8 |

7

1/4 |

19

5/8 |

63

3/4 |

5818 |

|

|

20 |

4

PS |

66 |

16/2.6 |

26.8/4.5

| H4 |

2x

0.9/0.2 |

7

7/8 |

7

1/4 |

19

5/8 |

63

3/4 |

7028 |

|

|

25 |

4

PS |

20 |

12/2.0 |

26.8/4.5

| H4 |

80/20 |

2x

0.9/0.2 |

7

7/8 |

7

1/4 |

19

5/8 |

63

3/4 |

5302 |

|

|

25 |

4

PS |

33 |

12/2.0 |

26.8/4.5

| H4 |

2x

0.9/0.2 |

7

7/8 |

7

1/4 |

19

5/8 |

63

3/4 |

5818 |

|

|

25 |

4

PS |

66 |

12/2.0 |

26.8/4.5

| H4 |

2x

0.9/0.2 |

7

7/8 |

7

1/4 |

19

5/8 |

63

3/4 |

7028 |

|

|

30 |

4

PS |

20 |

10/1.6 |

26.8/4.5

| H3 |

80/20 |

2x

0.9/0.2 |

7

7/8 |

7

1/4 |

19

5/8 |

63

3/4 |

5401 |

|

|

30 |

4

PS |

33 |

10/1.6 |

26.8/4.5

| H3 |

2x

0.9/0.2 |

7

7/8 |

7

1/4 |

19

5/8 |

63

3/4 |

5917 |

|

|

30 |

4

PS |

66 |

10/1.6 |

26.8/4.5

| H3 |

2x

0.9/0.2 |

7

7/8 |

7

1/4 |

19

5/8 |

63

3/4 |

7128 |

|

|

| Click

model number for detailed drawing |

|

| (*) Headroom

values may vary depending on trolley flange adjustment |

† Give proper

beam flange width when ordering, no extra charge. See standard flange range

table below.

Note: UL508A Labeled Controls is standard for all models |

|

|

|

Standard

Individual Flange Range Table |

Frame

Size |

Flange

ranges (in.) |

Frame

Size |

Flange

ranges (in.) |

Frame

Size |

Flange

ranges (in.) |

Frame

Size |

Flange

ranges (in.) |

Frame

Size |

Flange

ranges (in.) |

YKA |

3.248

- 5.700 |

YKB |

3.500

- 5.700 |

YKC |

4.680

- 5.700 |

YKD |

4.880

- 6.700 |

YKE |

7.280

- 8.700 |

5.701

- 7.700 |

5.701

- 7.700 |

5.701

- 7.900 |

6.701

- 8.700 |

8.701

- 14.200 |

7.701

- 9.850 |

7.701

- 9.850 |

7.901

- 9.850 |

8.701

- 11.800 |

14.201

- 19.700 |

9.851

- 12.050 |

9.851

- 12.050 |

9.851

- 12.250 |

11.801

- 15.750 |

|

12.051

- 13.780 |

12.051

- 13.780 |

12.251

- 15.750 |

15.751

- 19.700 |

|

13.781

- 15.750 |

13.781

- 15.750 |

15.751

- 19.700 |

|

|

15.751

- 17.750 |

15.751

- 17.750 |

|

|

|

17.751

- 19.700 |

17.751

- 19.700 |

|

|

|

|

| Other

flange ranges available on request. |

|

|

|

|

Standard

Allowable Flange Thickness Table |

Frame

Size |

Max.

Thickness

(in.) |

Frame

Size |

Max.

Thickness

(in.) |

Frame

Size |

Max.

Thickness

(in.) |

Frame

Size |

Max.

Thickness

(in.) |

Frame

Size |

Max.

Thickness

(in.) |

YKA |

0.9 |

YKB |

1 |

YKC |

1.39 |

YKD |

1.75 |

YKE |

1.75 |

|

| Other

flange ranges available on request. |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

|

|

|

|

|

|

OPTIONS

FOR YK MONORAIL HOIST & TROLLEY |

|

|

|

|

|

| Metric

Rated Hoists |

|

|

Short

Tons |

Metric

Rating KG

| Short

Tons |

Metric

Rating KG

| Price |

1 |

900 |

7.5 |

6800 |

No

Charge |

2 |

1800 |

9 |

8000 |

2.5 |

2250 |

10 |

9000 |

2.75 |

2500 |

12.5 |

11000 |

3 |

2700 |

15 |

13600 |

4 |

3600 |

20 |

18000 |

5 |

4500 |

25 |

22000 |

6 |

5400 |

30 |

27200 |

|

|

|

|

Capacity

labeled as Metric.

However, please consult

customer service if FEM / ISO

compliance is required! |

|

|

|

Travel

Limit Switch |

Price |

Slow

down and stop switching for 208V, 230V or 460V |

|

A travel

limit switch can be mounted on the KE trolley to limit the cross

travel.

The standard version has the following functions: |

- Limit

switching in both directions of travel |

- Switching

from "fast" to "slow" |

- Travel

limit switch is wired and mounted to the hoist. |

- The

switch activator mounted on the runway must be provided by the customer. |

- Protection

class IP 65 |

Towing

arm for power supply: |

Standard

arm length: 19 7/8" |

|

Note:

The height and length of the towing arm is adjustable and can be

used for both festoon cable and conductor bar applications.

Mounted to the hoist gearbox side. |

Patented

track wheels: |

YKA -

Flange width: 3 1/4 - Clearance between wheels: 1.181'' |

Standard |

YKB -

Flange width: 3 1/4 - Clearance between wheels: 1.181'' |

|

Note:

The YKA and YKB hoists can be used on a straight patented track

beam with a minimum flange width of 3 1/4".

YKB hoists are available up to 7 1/2 Ton. |

|

| Variable

Frequency Trolley Control for Monorail Trolley - Note: VFD Trolley (with

2-Speed Lift) |

Hoist

Model |

Standard

2-Speed

Trolley HP |

Standard

Trolley Motor HP |

Voltage |

Price |

YKA,

YKB & YKC

(up to 10 Ton) |

0.6 |

1.2 |

460,

230,

or 208v |

|

0.9 |

1.2 |

YKC

12.5 Ton & YKD 15 ton |

2 |

1.2 |

|

YKC

15 ton |

2 |

3.5 |

|

YKE |

2 x

0.9

| 2 x

1.2

| |

Note:

2 step infinitely variable. Standard speed 80fpm with 10:1 speed

range |

WIRE

ROPE CERTIFICATE |

Wire

Rope Certificate with Breaking Strength |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

| PANEL

& MOTOR HEATER |

460

volt |

Monorail

Trolley |

2

Speed Hoist

& Trolley |

2

Speed Hoist /VFD Trolley

or VFD Hoist / VFD Trolley |

YKA,

YKB |

|

|

YKC |

|

|

YKD,

YKE |

|

|

208V/230V |

Monorail

Trolley |

2

Speed Hoist & Trolley |

2

Speed Hoist / VFD Trolley Only |

YKA,

YKB |

|

|

YKC |

|

|

YKD,

YKE |

|

|

|

Panels

are rated Nema 4/12

Motors heaters include IP66 protection |

|

We recommend

Panel & Motor heaters if ambient temperature reaches below -4° Fahrenheit

or if ambient humidity exceeds 80%.

Panel heaters will start when the the temperature drops below 50° F. |

|

| MAGNETEK

VARIABLE FREQUENCY DRIVES |

|

|

|

|

Combining Magnetek's

reliable IMPULSE® Variable

Frequency Drives with the YK's industry-leading

design creates a one-of-akind, intelligent option for lifting

applications. IMPULSE drives continuously monitor

many environmental and functional components of a

hoist, such as motor temperature, end of travel and slow

down limits, brake functionality, motor speed, and more.

Variable frequency drives maintain safe functional thres-

holds, which decreases mechanical fatigue and increases

reliability and uptime. |

|

Hardware and software

are designed and extensively

tested specifically for the operating conditions seen in

overhead material handling applications. IMPULSE·G+

Mini is available for monorail, double girder, and base

mount hoists with load capacities up to 30 tons. |

|

|

|

|

|

|

|

|

|

For trolley motion,

the IMPULSE®·G+ Mini drive

allows for expanded speed adjustments, improved load

control, high duty cycles, and increased crane life. The

IMPULSE·G+ Mini's size permits the use of smaller

control enclosures, reducing the overall cost of an

installation. |

|

|

|

|

|

|

|

|

|

| IMPULSE•G+

MINI STANDARD FEATURES |

|

|

|

|

|

SAFE

OPERATING WINDOWS™

Reduce the possibility of programming

unsafe parameters. |

|

QUICK STOP™

Reduces the possibility of crane collision. |

|

|

|

|

|

SWIFT-LIFT™

Allows overspeeding with light loads

or empty hook. |

|

|

|

|

|

MOTOR

THERMAL OVERLOAD

PROTECTION

Reduces the possibility of motor damage. |

|

|

|

|

|

|

REVERSE PLUG

SIMULATION™

Allows operators to smoothly and

quickly stop and change directions

without setting the brake. |

|

|

|

|

|

X-PRESS

PROGRAMMING™

Allows programming for initial setup

within seconds. |

|

|

|

|

|

|

|

|

|

|

AUTO-TUNING

Non-rational auto-tuning for performance

demanding applications. |

|

UL RECOGNIZED

ELECTRONIC

THERMAL OVERLOAD |

|

|

|

|

|

|

|

|

For

hoist motion, the IMPULSE®·VG+ Series 4 drive

provides reliable, user-friendly controls and industry-leading

features to keep you working safely. |

|

|

|

The

easy-to-use keypad provides five lines of 16 characters

each and includes soft keys and upgraded parameter

selection. The display makes navigation and reading

diagnostics even easier. |

|

|

| Allows

For: |

|

• Programming various drive parameters

• Parameter backup (store

and copy)

• Monitoring functions of the drive

• Reading of alpha-numeric fault diagnostic

instructions

• Remote monitoring |

|

|

| IMPULSE•VG+

STANDARD FEATURES |

| *Features

are configurable by user |

|

|

|

|

|

ENCODER FEEDBACK

IMPULSE drives continuously monitor motor speed

and load to ensure optimal performance and safe

load control. |

|

SHORT CIRCUIT

PROTECTION

Detects if a motor has a short circuit and can prevent

additional failure of the control system. |

|

|

|

|

LOAD

CHECK II™*

Continuously monitors hoist overload conditions, halting

upward motion and only allowing the load to be lowered. |

|

|

DYNAMIC BRAKING

Dynamically decelerates motors without the use of

brakes. Brakes would only be used for parking and

emergency braking, reducing brake pad wear and tear. |

|

|

|

|

|

PROGRAMMABLE

LIMIT SWITCHES*

Allow for configurable slow down and stop limits

based on encoder pulses without additional hardware. |

|

|

ANTI-SHOCK*

Automatically stabilizes loads by detecting and minimizing

rapid increases in motor torque, reducing the potential for

crane damage. |

|

|

|

|

|

SLACK

CABLE DETECTION*

Provides annunciation of slack cable condition to

operators. |

|

|

ULTRA-LIFT™*

Allows over speeding with light loads or empty hook.

Motor speed can be adjusted to operate at peak

performance. |

|

|

|

|

PHASE LOSS DETECTION

Detects if incoming power phase is lost and maintains

a safe state of the load. |

|

|

|

|

TORQUE

PROVING AT START

Determines if the motor can safely control a load before

opening the brake to provide additional safety. |

|

|

LOAD FLOAT™

Allows a load to be held aloft at zero speed without

setting the electric brake. This reduces wear and

increases hoist lift response time. |

|

|

|

|

|

MICRO-SPEED™*

Allows operators to scale motor speed, which is useful

for load positioning. |

|

|

BRAKE CHECK

AT STOP

Tests that brakes can safely hold a load at the end

of a run and the motor will maintain control of the

load in case of brake failure. |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

|

PRICING

FOR MAGNETEK VFD FOR HOIST & TROLLEY CONTROL

2-STEP INFINITELY VARIABLE CONTROL |

*Frame

Size |

Std

2-Speed

Hoist

Motor

HP |

Std.

2-Speed

Trolley

HP |

Inverter

Duty Hoist

Motor HP |

VFD

Trolley

Motor

HP |

2

Part

Reeved

Cap. (tons) |

4

Part

Reeved

Cap. (tons) |

**

Volt |

VFD

Hoist

& Trolley

Price Adder |

YKA |

3.9 |

0.6 |

7.2 |

1.2 |

1 |

2,

2 1/2, & 3 |

460 |

|

YKB |

7.8 |

0.6 |

7.2 |

1.2 |

2,

2 3/4, & 3 |

4,

5, 6, & 7.5 |

460 |

|

YKC

up to 10 ton |

14.8 |

0.9 |

14.8 |

1.2 |

3,

4, 5, 6, & 7.5 |

7.5,

9, 10,

& 12.5 |

460 |

|

YKC

12 ton &15 ton

(13 fpm) |

14.8 |

3.5 |

14.8 |

3.5 |

n/a |

12

& 15 |

460 |

|

YKC

15 ton (25 fpm) |

26.8 |

2 |

28 |

3.5 |

n/a |

15 |

460 |

|

YKD

7.5 ton (2PS) |

26.8 |

0.6 |

14.8 |

1.2 |

7.5 |

n/a |

460 |

|

YKD

15 ton |

26.8 |

2 |

28 |

3.5 |

n/a |

15 |

460 |

|

YKE |

26.8 |

2

x .9 |

28 |

2

x 1.2

| n/a |

20,

25, 30 |

460 |

|

|

| ** VFD

H&T available for 460v only. |

|

|

|

|

Hoist

Lift |

*2-Speed

2H 2T & E-Stop |

Adder

for additional

Pushbuttons (per pair)

*2-speed/2-step |

20

ft. |

|

|

28

ft. |

|

33

ft. |

|

39

ft. |

|

40

ft. |

|

46

ft. |

|

56

ft. |

|

66

ft. |

|

93

ft. |

|

131

ft. |

|

|

|

PUSHBUTTON STATIONS

(SHIPPED LOOSE) |

|

|

|

Pushbutton stations

are NOT included in Base Hoist

Price. Prices are arranged by the various button

combinations available per hoist lift. Price includes IP65

(Type 4 Equivalent) pendant station below with the

button quantity listed, control and strain-relief cable for

the hoist lift selected. The length of the cables will be

approximately equal to the lift less 4 feet. The pendant

will ship loose for field installation by others unless

otherwise specified. |

|

|

|

For Crane Mfg control

hoist - Pendant is either

shipped loose or not supplied. |

|

|

|

For Complete (includes

mainline and transformer)

control hoist - Pendant is either mounted or not

supplied. |

|

|

|

Attach and wire pendant

to hoist add ................ $140.34 |

|

Additional pendant

drop add ............................... $9.70/ft. |

|

|

|

|

|

* May

be used for for 2-step infinitely variable VFD Hoist & Trolley motion

3-step infinitely variable hoist & trolley control is Priced on Application |

|

|

|

| RADIO

REMOTE CONTROLS |

|

|

|

Magnetek's Flex

EX2 series of radio remote controls

are durable, rugged, and equipped with more than

200 programmable functions for system customization.

A frequency agility feature automatically switches

channels when interference is detected, and advanced

synthesized RF controls with 124 channels add flexibility

to frequency management in the field. IP66-rated, fully

sealed transmitter and receiver enclosures provide

protection in harsh environments. |

|

Flex EX2 is available for all

current wire rope

hoist models, as well as crane kits with optional

plug-and-play connector. |

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

Magnetek

Radious |

Price |

Flex

4Ex Radio (2 motion) |

|

Flex

6Ex Radio (3 motion) |

|

Radio

mounted on hoist using quick connectors. |

|

Horn |

Price |

Horn

mounted on radio receiver (96db @ 1 meter) |

$139 (does not include radio) |

External

Horn mounted on hoist (adjustable 88-113db @1 meter) |

|

|

|

|

Includes

two transmitters

Horn is Pushbutton activated. |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

| YK HOIST SPARE

PARTS KIT |

| APPLICABLE

ONLY WHEN PURCHASED WITH A NEW HOIST |

|

2

PS REEVING |

Lift |

1

Ton |

2

Tons |

2

3/4 Tons |

3

Tons |

4

Tons |

5

Tons |

7

1/2 tons |

20' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

28' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

33' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

39' |

|

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

40' |

N/A |

|

|

|

|

|

|

46' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

66' |

|

|

|

|

|

|

|

93' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

131' |

N/A |

N/A |

|

|

|

|

N/A |

|

|

4

PS REEVING |

Lift |

2

Ton |

2

3/4 Tons |

3

Tons |

4

Tons |

5

Tons |

6

Tons |

7

1/2 tons |

20' |

|

|

|

|

|

|

|

28' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

33' |

|

|

|

|

|

|

|

39' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

40' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

|

46' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

66' |

N/A |

N/A |

N/A |

|

|

N/A |

|

93' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

|

131' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

|

|

|

|

|

4

PS REEVING |

Lift |

9

Ton |

10

Tons |

12

1/2 Tons |

15

Tons |

20

Tons |

25

Tons |

30

tons |

20' |

|

|

|

|

|

|

|

28' |

N/A |

N/A |

N/A |

|

N/A |

N/A |

N/A |

33' |

|

|

|

|

|

|

|

39' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

40' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

46' |

N/A |

N/A |

N/A |

|

N/A |

N/A |

N/A |

66' |

|

|

N/A |

N/A |

|

|

|

93' |

N/A |

N/A |

N/A |

|

N/A |

N/A |

N/A |

131' |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

|

|

|

|

|

| Kit

includes the following hoist motion only parts: |

|

|

|

Wire Rope Assembly

Wire Rope Lube

Rope Guide

Spring Tool

Hook Safety Latch

Hoist Brake Disc

Trolley Brake Disc

Fan Wheel Set |

|

|

|

Spare SLE3 Monitoring

Device, add $1,457 |

|

|

Electric Wire Rope Hoists,

Wire Rope Hoist, Electric Hoist, Trolleys, Hoists, Yale, Winch Hoist,

Winches, Electric Powered Winches,

Monorail Hoist, YK, Global King, and Hoist Winches from your source for

material handling equipment. |

Back

to Product Category |

|

|