|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

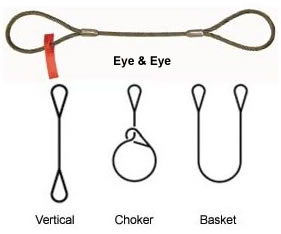

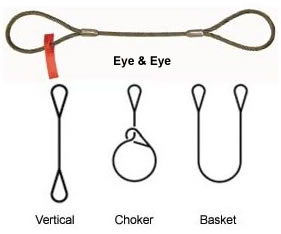

EYE

& EYE WIRE ROPE & SLINGS

|

TYPE

IMP PERMALOC WIRE ROPE SLINGS

|

Our

Permaloc Slings are made using the flemish splice technique to form the

eyes. Unlike the simple return loop

method that places 100% of its strength on the swaged sleeve, Permaloc slings

have reserve strength should the

sleeve become damaged in use. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Features

and Benefits |

|

|

|

|

Maintains

all the basic wire rope sling features plus ... |

|

|

|

|

Promotes

Safety |

|

|

|

|

Reserve strength - integrity of eyes not solely dependent Reserve strength - integrity of eyes not solely dependent

upon steel sleeves |

|

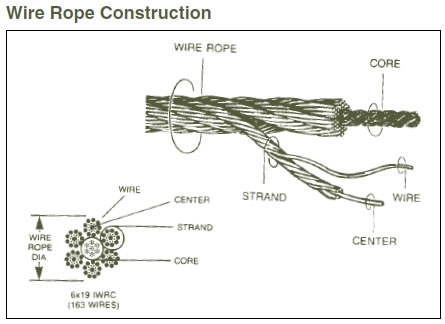

IWRC resists crushing better

than FC ropes IWRC resists crushing better

than FC ropes |

|

|

|

|

Saves Money |

|

|

|

|

|

When specified, thimble eyes protect wire rope from When specified, thimble eyes protect wire rope from

wear for increased life |

|

Good abrasion resistance for longer life Good abrasion resistance for longer life |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

|

*Contact

Us For Special Lengths* |

|

|

|

|

|

|

|

|

|

| PRICING

FOR PERMALOC EYE & EYE WIRE ROPE SLING |

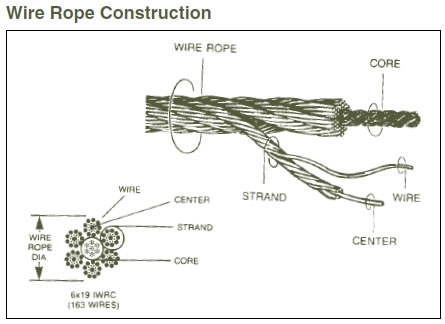

| IWRC

(Independent Wire Rope Core) |

|

| Fiber

core available at reduced capacities |

|

EIP,

IWRC |

¹Min.

Sling

Length |

Std.

Eye

Size

(in.)

W x L |

PRICE |

| Rated

Capacity (tons)* |

|

|

|

6

x 19 EIP, IWRC 6

x 19 EIP, IWRC |

| |

|

|

|

|

|

3 |

4 |

6 |

8 |

10 |

| 1/4 |

0.65 |

0.48 |

1.3 |

1' 6" |

2 x 4 |

|

|

|

|

|

| 5/16 |

1 |

0.74 |

2 |

1' 9" |

2 1/2 x 5 |

|

|

|

|

|

| 3/8 |

1.4 |

1.1 |

2.9 |

2' 0" |

3 x 6 |

|

|

|

|

|

| 7/16 |

1.9 |

1.4 |

3.9 |

2' 3" |

3 1/2 x7 |

|

|

|

|

|

| 1/2 |

2.5 |

1.9 |

5.1 |

2' 6" |

4 x 8 |

|

|

|

|

|

| 9/16 |

3.2 |

2.4 |

6.4 |

2' 9" |

4 1/2 x 9 |

|

|

|

|

|

| 5/8 |

3.9 |

2.9 |

7.8 |

3' 0" |

5 x 10 |

|

|

|

|

|

| 3/4 |

5.6 |

4.1 |

11 |

3' 6" |

6 x 12 |

|

|

|

|

|

| 7/8 |

7.6 |

5.6 |

15 |

4' 0" |

7 x 14 |

|

|

|

|

|

| 1 |

9.8 |

7.2 |

20 |

4' 6" |

8 x 16 |

|

|

|

|

|

| 1 1/8 |

12 |

9.1 |

24 |

5' 0" |

9 x 18 |

|

|

|

|

|

6

x 37 EIP, IWRC 6

x 37 EIP, IWRC |

| 1 1/4 |

15 |

11 |

30 |

5' 6" |

10 x 20 |

|

|

|

|

|

| 1 3/8 |

18 |

13 |

36 |

6' 0" |

11 x 22 |

|

|

|

|

|

| 1 1/2 |

21 |

16 |

42 |

7' 0" |

12 x 24 |

|

|

|

|

|

| 1 3/4 |

28 |

21 |

57 |

8' 0" |

14 x 28 |

|

|

|

|

|

| 2 |

37 |

28 |

73 |

9' 0" |

16 x 32 |

|

|

|

|

|

|

| Note: Larger diameter slings available. Basket ratings are based on a minimum

D/d of 25. |

| ¹

Minimum sling length when using standard eyes. |

|

|

|

* * |

Do

not exceed rated capacities. Sling capacity decreases as the angle from

horizontal decreases. Slings

should not be used at angles of less than 30°. Refer to Effect of Angle

chart below. |

|

|

|

|

|

| Above

rope prices are domestic, for imported rope call us. |

|

| Slings

shorter than min. lengths listed may require reduced capacity ratings and/or

eye lengths. |

|

|

|

|

|

|

|

|

|

|

| EFFECT

OF SLING ANGLE |

|

|

|

|

|

|

|

|

|

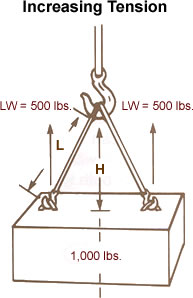

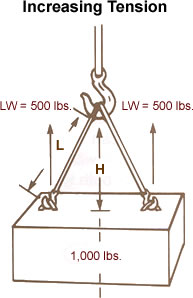

Using

slings at an angle can become deadly if that angle is not taken into

consideration when selecting the sling to

be used. The tension on each leg of the sling is increased as the angle

of lift, from horizontal, decreases. It is most

desirable for a sling to have a larger angle of lift, approaching 90°.

Lifts with angles of less than 30° from horizontal

are not recommended. If you can measure the angle of lift or the length

and height of the sling as rigged, you can

determine the properly rated sling for your lift. The Increased Tension

method provides the increased tension as a

function of the sling angle. Alternatively, the sling Reduced Capacity method

may be used to determine reduced lift

capacity for any angle. |

|

|

|

|

|

|

|

|

|

INCREASED

TENSION

Determine capacity

of sling needed |

|

REDUCED

CAPACITY

Calculate rating of each sling

rigged at this angle |

|

|

|

|

|

| 1.

Determine the load weight (LW). |

1.

Calculate the reduction factor (RF). |

|

|

|

|

a.

Using the angle from horizontal,

read across the Angle Chart to

the corresponding number of the

Reduction Factor column. |

| 2.

Calculate the Tension Factor [TF]. |

|

|

a.

Determine the sling angle as mea-

sured from the horizontal, and the

corresponding tension factor (TF)

from the effect of angle chart. |

|

|

|

-OR- |

|

|

b.

Divide sling height* (H) by sling

length* (L). |

|

-OR- |

|

|

|

b.

Length* (L) divided by height*

(H) |

|

|

|

|

|

2.

Reduction factor (RF) x the sling’s

rated capacity for the type hitch that

will be used = sling’s reduced rating. |

|

|

|

|

|

|

|

|

|

|

|

|

3.

Determine the share of the load

applied to each sling leg (LW). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.

Multiply (LW) by (TF) to determine

the sling leg tension. The capacity of

the selected sling or sling leg must

meet the calculated tension value. |

|

|

*Measured

from a common horizontal

plane to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

*Measured

from a common horizontal plane

to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Effect

of Angle Chart |

|

|

|

|

Tension

Factor (TF) |

Angle From

Horizontal |

Reduction

Factor (RF) |

| 1.000 |

90º |

1.000 |

| 1.004 |

85º |

0.996 |

| 1.015 |

80º |

0.985 |

| 1.035 |

75º |

0.966 |

| 1.064 |

70º |

0.940 |

| 1.104 |

65º |

0.906 |

| 1.155 |

60º |

0.866 |

| 1.221 |

55º |

0.819 |

| 1.305 |

50º |

0.766 |

| 1.414 |

45º |

0.707 |

| 1.555 |

40º |

0.643 |

| 1.742 |

35º |

0.574 |

| 2.000 |

30º |

0.500 |

|

|

|

|

|

|

|

|

|

Example: |

|

|

|

Vertical

Choker rating of each sling:

6,000 lbs.

Measured Length (L) = 6 ft.

Measured Height (H) = 4 ft.

Reduction Factor (RF) = 4 (H) ÷ 6 (L) = .667 |

|

|

|

|

| Example: |

|

|

|

Load

weight = 1,000 lbs.

Rigging - 2 slings in vertical hitch

Lifting Weight (LW) per sling = 500 lbs.

Measured Length (L) = 10 ft.

Measured Height (H) = 5 ft.

Tension Factor (TF) = 10 (L) ÷ 5 (H) = 2.0

Minimum Vertical Rated Capacity required

for this lift = 500 (LW) x 2.0 (TF) = 1000 lbs.

per sling |

|

Sling

capacity decreases as the angle

from horizontal decreases. Sling angles

of less than 30° are not recommended. |

|

|

Reduced

sling rating in this configuration

= .667 |

|

(RF)

x 6,000 lbs. = 4,000 lbs. of lifting

capacity per sling |

|

|

|

|

|

|

|

Wire Rope Slings, Wire Rope

& Slings, Lifting Slings, Lift-All, Sling, Proof Testing, Certification,

Sliding Choker,

Eye & Eye, Eye & Thimble, Eye & Hook, Thimble & Hook,

Permaloc, IWRC, 6 x 19 EIP, 6 x 37 EIP, Hooks,

and Thimbles from your source for material handling equipment. |

Back

to Product Category |

|

|