|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back

to Product Category

| |

Standard

"Quick-Ship" Modular Offices

|

|

|

|

|

|

Installation

Instructions

|

|

|

|

|

|

|

Important:

We advise a thorough reading of these instructions before

beginning installation.

|

|

|

|

|

|

|

|

Introduction

|

|

|

|

|

|

|

|

|

|

Instructions

should be read thoroughly and cross-referenced with your job

drawings prior to commencing

installation.

Standard "Quick-Ship" Modular Offices are manufactured

from high quality materials with care taken in handling

and packing at the factory. Please inspect your materials

and count them to make sure that damage or loss has not

occurred in transit. Please notify us promptly if you experience

any problems. Review the accompanying Bill of

Materials and parts drawings to familiarize yourself with

the components of the system. Care must be exercised in

handling these materials. The framing parts are made from

painted steel and anodized aluminum. The material,

while strong and durable, will scratch, bend and/or mar. Normal

care in erection will result in a finished product of

which we both will be proud.

|

|

|

|

|

|

|

|

|

|

Tool

Suggestions

|

|

|

|

|

|

|

|

|

|

•

Hammer

• Rubber Mallet & Wood Block

• Electric Drill

• #30 Drill Bits (3 or 4)

• Phillip's Screwdriver

• 12 Ga. Extension Cord

• Putty Knife or Trowel (4" Blade)

• Level (30"or Longer)

|

|

•

Plumb Bob

• Chalk Line & Dry Line

• Tape Measure or Ruler

• Tin snips

• Pliers

• Hacksaw

• Pencil

• Ladder |

|

•

Carpenter's Square

• 9/16" Socket w/Ratchet

• 9/16" Wrench

• 5/16" Drive Socket

• 3/8" Drive Socket

• Fiberboard Knife

• Broom |

|

|

|

|

|

|

|

|

|

Unpacking,

Inspection & Inventory

|

|

|

|

|

|

The

Modular Office wall system is packaged in the factory in a

manner to protect each part during normal shipping

and handling. It is recommended that the original packaging

remain intact as much as possible until the individual

parts are needed. All extrusion components are typically packaged

in boxes. Panels are shipped with a foam

interleaf between panels.

As the skids are received at the job-site, they should be

placed in a location near the installation area, where they

will not become an obstacle, or require to be moved at a later

time. The skids should then be opened, however

leaving the internal packaging unchanged. Pieces can be removed

on an as needed basis and the packaging

discarded then. At this time the components should be visually

inspected for obvious damage and an inventory

taken to confirm that all parts are received as expected.

Notify us immediately of any discrepancies.

|

|

|

|

|

|

Fasteners

Not Provided

|

|

|

|

|

|

The

attachment hardware for the floor track to the flooring and

wall starters to existing structures are not included

due to installer preferences, local codes, and varying flooring

and ceiling systems.

The following are recommendations:

• Concrete floor: powder

actuated fasteners: heavy duty dome head nail – type

DS 1-1/4" long

• Wood floor: 1/4"

x 1" lag bolt

• Steel floor: #14 x 1"

sheet metal screws

• Drywall: 1/4" toggle

bolts, drywall or wood screws

|

|

|

|

|

|

Installer

Tip!

|

|

|

|

|

|

To

save time, mark the centerlines of all the studs on the floor

in front of the floor track. This will assist you in

maintaining the centerlines shown on the drawings.

|

|

|

|

|

|

Floor

Track Installation

|

|

|

|

|

|

|

|

|

|

|

|

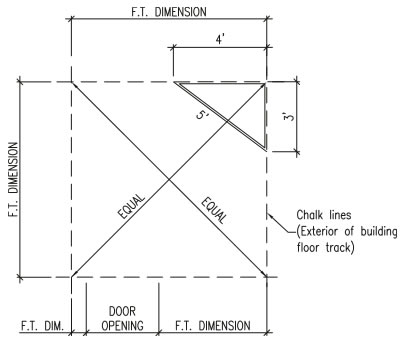

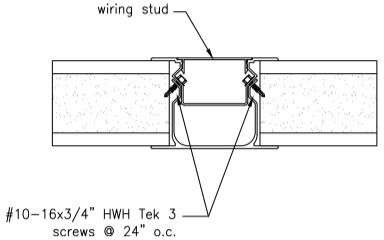

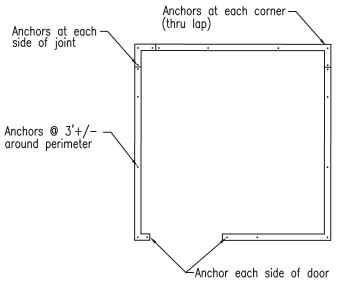

Step

1

Locate the first wall and strike a chalk line

on the floor. This line is the outside edge of your

floor track.

Step 2 Lay out the floor track per floor plan

drawings. Cut floor track length as noted by F.T.

dimensions on the drawing. Use metal snips to cut

the floor track lengths. Note: Use the 3 - 4 - 5

triangle method or a carpenter's square to confirm

90° corners. (Detail A)

Step 3 Mark wiring stud centerlines & door

openings per plans. (Note: It is imperative that

stud centerlines be maintained.)

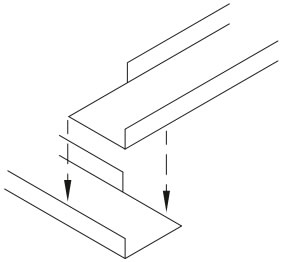

Step 4 Notch corner locations (Detail B) to allow

ends to lap each other.

Step 5 Refer to (Detail C) when securing floor

track to surface with floor anchors.

|

|

|

|

|

|

Detail

A - Floor Plan

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

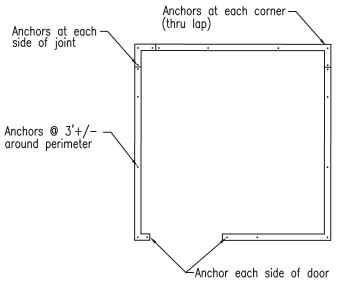

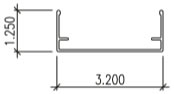

Detail

B - Corner Lap Detail

|

|

|

|

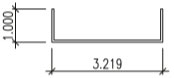

Detail

C - Floor Track Layout

|

|

|

|

|

|

|

|

|

|

|

|

|

Pre-Assemble

Stud Posts

|

|

|

|

|

|

|

|

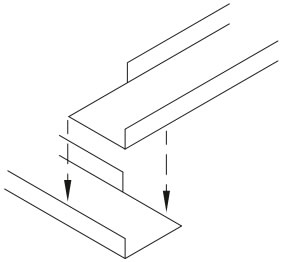

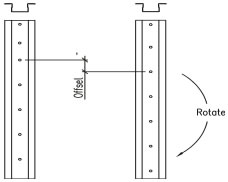

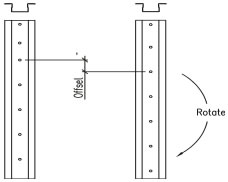

The

holes of a stud hat have an offset pattern that allows two

identical hats to

be secured together by rotating one of the hat sections. This

alignment will

offset the holes, allowing the standard #10-16 x 3/4"

Tek 2 screw to use a pre-punched hole on one hat and to tap

through the opposing hat. (Detail D)

Assemble stud posts. Leave out the cover strips until Step

#8 of Electrical

Section.

Screw the stud sections together leaving the sections loose

enough to install

the panel.

|

|

|

|

|

|

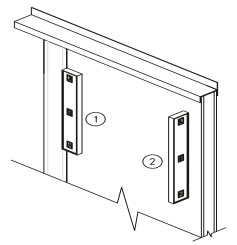

Detail

D

|

|

|

|

|

|

|

|

|

|

|

|

The

holes of a Series 300 stud hat are prepunched on both sides

of the raceway at 12" o.c. Assemble stud assembly by inserting

Part A into Part B. Using a #10-16 x 3/4" Tek 2 screw fasten

the two parts together using a prepunched hole on Part A to

tap through the opposing Part B. |

|

|

|

|

|

|

|

Wall

Erection

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wall

panels are fabricated and ready to install. Standard wall

panels are 44-7/8" wide and are interchangeable with

other full panels, windows and door panels. Special width

filler panels (F.P.) are labeled on floor plan.

Step 6 Check the floor for level. In extreme cases

(out of level by 1/2" or more) select the high corner

as your

starting point. If possible, leave the door panel to be installed

last. Shimming may be necessary if floor surface is

not very level.

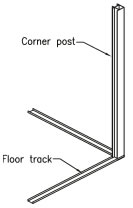

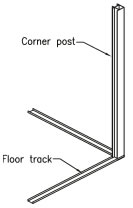

Step 7 Begin wall installation by inserting a corner

post into the floor track (Detail E). Note:

the corner post is

inside both the vertical legs of the floor track. The corner

post should be loosely assembled using Phillip's flat head

1/4"-14 x 3/4" screws to allow install of panel.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

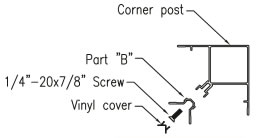

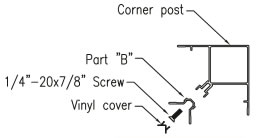

Detail

G

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Installer

Tip!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When

installing the panels into the stud, pull the panel back on

one corner and slide the other

corner into the stud or corner. |

|

|

|

|

|

|

|

|

|

|

Detail

E

|

|

Detail

F

|

|

|

|

|

|

|

|

|

|

|

|

|

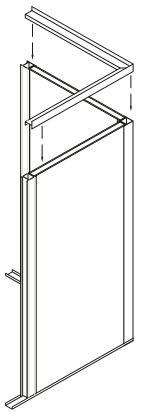

Step

8

Install the two adjacent corner wall panels into the floor

track and slide gently into corner post (Detail F). Tighten

the

corner post screws and install vinyl corner inserts (Detail

G). |

|

|

|

|

|

|

|

|

|

|

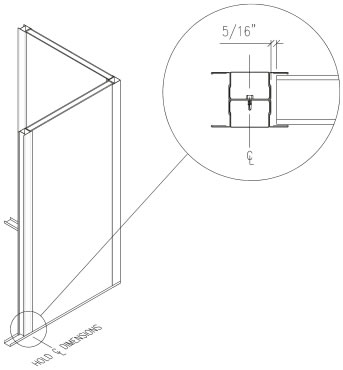

Installation

Note

|

|

|

|

|

|

|

|

|

|

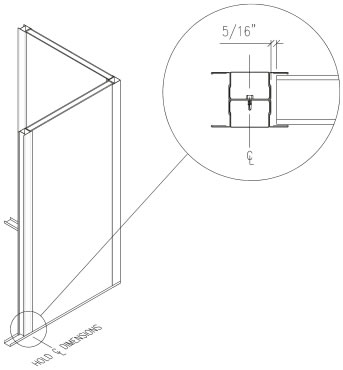

Do

NOT push panel all the way into the stud. Hold centerline dimension. |

|

|

|

|

|

|

|

|

|

|

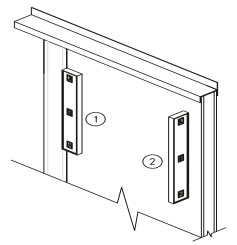

Step

9 Install

pre-assembled studs next to each panel.

Check centerline dimension of stud to corner post from your

floor plan.

Tighten screws after panel is in place (Detail H).

Refer to the fastener guide for screws required. Do not over

tighten screws.

|

|

|

|

|

|

|

Detail

H

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Load-Bearing

Office

|

|

|

|

|

|

|

|

|

|

|

Install

a 10 gauge bearing plate inside the floor track below

each stud and corner. Use 3-3/16" x 5" plate for studs

and

4-1/2" x 4-1/2" notched plate for corners. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Step

10

Assemble mitered

cornice mold corner assembly

(Detail I). Each standard corner includes two short pieces

of

cornice mold with one end

mitered. These special pieces

will be used to make your

cornice mold corners. If corner

to stud dimensions is less than

50-1/4", field cut the cornice

mold so that the end not mitered falls on the centerline of

the

stud. Secure cornice mold

corners to the interior side of

the corner post w/ #10-16 x 3/4"

Tek 3 screws.

Step 11 Insert next panel into

floor track; slide into stud and

tighten screw. (Note: Do not

over tighten screws). Continue toward next corner. Check each

panel for plumb (Detail J). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

J

1. Check stud

for plumb.

2. Check wall

for plumb.

|

|

|

|

|

|

|

|

|

|

Detail

I

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Step

12

Check the centerline dimension of each stud with the dimensions

on your floor plan. This will eliminate any growth or shrinkage

of the overall dimension.

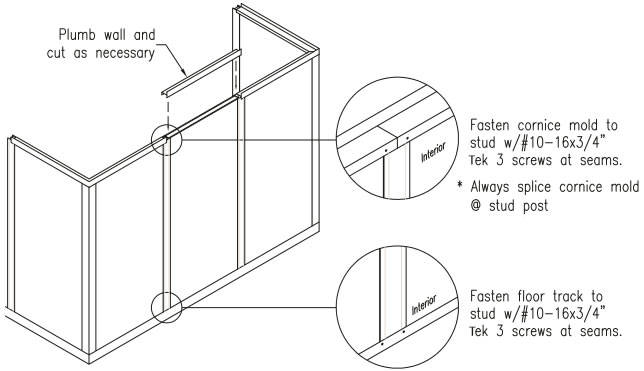

Step 13 Set cornice mold in place. If necessary, cut

the cornice mold so that it fits between the two cornice mold

corners you have assembled.

Step 14 Recheck the wall and corners for plumb. Secure

the stud through the cornice mold and floor track on the interior

side of wall at each stud location with #10-16 x 3/4"

Tek 3 screws (Detail K).

Step

15

Install the remaining walls in the same manner.

|

|

|

|

|

|

|

|

|

Detail

K

|

|

|

|

|

|

|

|

|

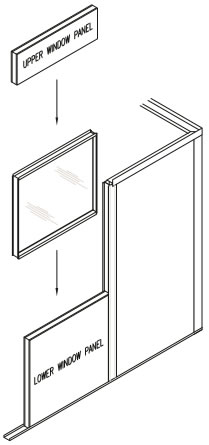

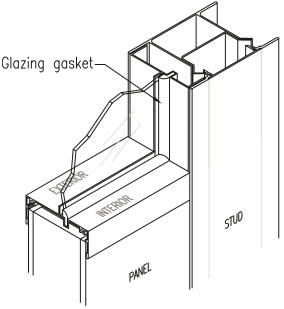

Window

Panels

|

|

|

|

|

|

|

|

|

|

|

|

|

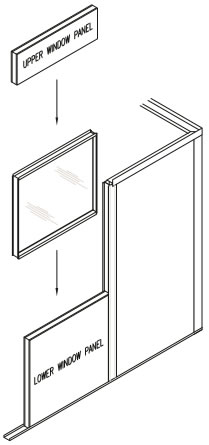

Window

panels install into the stud in the same manner as the wall

panels.

Step 16 Insert the lower window panel in the adjacent stud.

(Detail L)

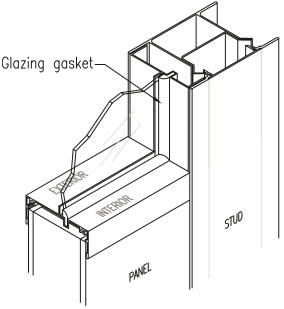

Step 17 Install the window onto the lower window panel

with the gasket to

the inside of the room. (Detail M) Handle with care. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

L

|

|

|

Detail

M

|

|

|

|

|

|

|

|

|

|

|

|

Step

18

Insert the upper window panel. (Detail L)

Step 19 Slide on the adjacent stud and proceed with the

next panel.

Note: To prevent breakage, we recommend the window be

moved only in an upright position with the bottom

supported.

For a neat job, make certain that the window frames are inserted

completely into the studs and the sill heights

align. If the wall consists of many window units it is imperative

the windows be inserted all the way into the studs

and you check your centerline dimension of your studs to make

sure they match the drawing; otherwise the wall

will grow in length and the last unit will not fit into the

corner. |

|

|

|

|

|

|

|

|

|

|

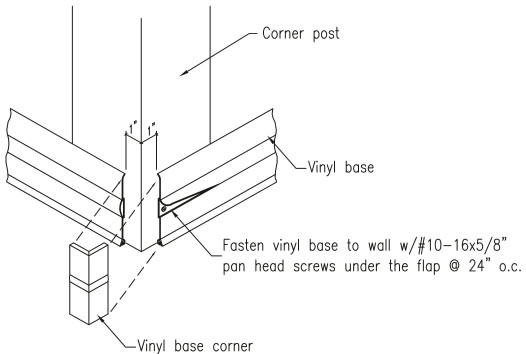

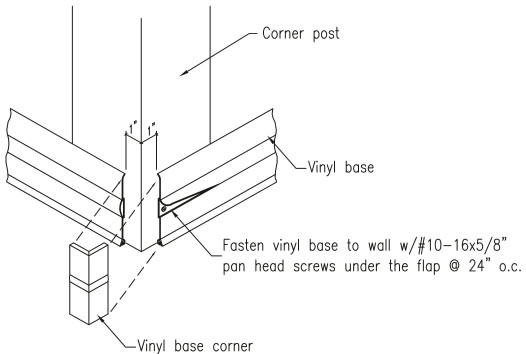

Vinyl

Base

|

|

|

|

|

|

|

|

Step

20 The screw on vinyl base should be cut to fit for the

interior and exterior of the room. Lift cover flap and

secure to wall with #10-16 x 5/8" pan head screws at

24" centers. Push the cover strip in, to lock in place,

and

cover screw heads. Pre-formed exterior corners are supplied

for the outside corners only. (Detail N)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

N

|

|

|

|

|

|

|

|

|

Single

Door Installation

|

|

|

|

|

|

|

|

|

|

|

|

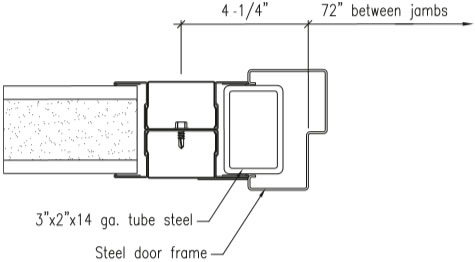

The

door and frame come pre-installed in a full size wall panel.

Handle door assembly panel with care and lift the

panel from the sides, not the ends. |

|

|

|

|

|

|

|

|

|

|

|

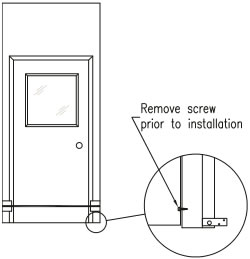

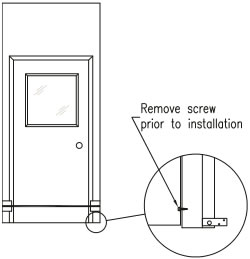

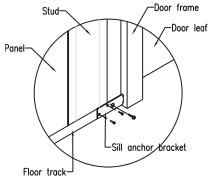

Step

1 For handling purposes, the bottom of the door is fastened

to the

door frame. This must be removed before installing the door

assembly

panel. Also verify at this point that the floor track opening

is 37-3/8".

(Detail O)

Install the door assembly panel into the floor track. The

floor track will fit between the door frame and the panel.

Be sure the wall with the door is

installed with cornice mold attached to studs before adjusting

door.

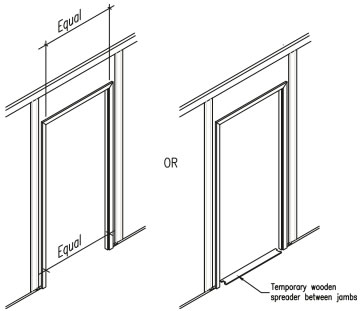

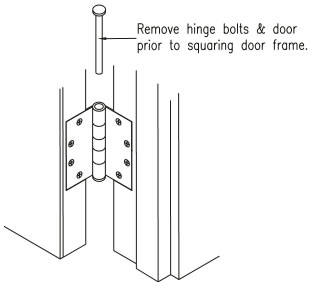

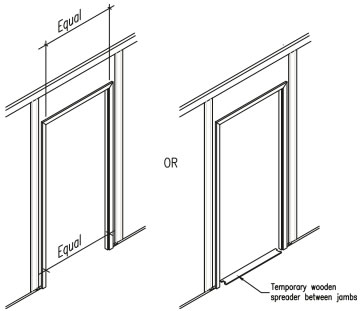

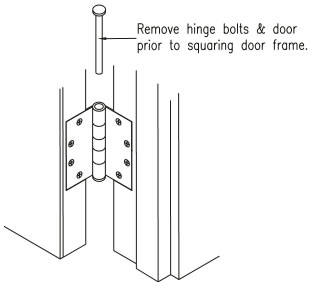

Step 2 Remove hinge bolts and door prior to squaring/leveling

door

frame. (Detail Q)

Step 3 Verify there is equal spacing between both jambs

by measuring or

by using a temporary wooden spreader. (Detail P)

|

|

|

|

|

|

Detail

O

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

P

|

|

Detail

Q

|

|

|

|

|

|

|

|

|

|

|

|

|

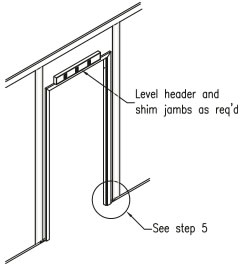

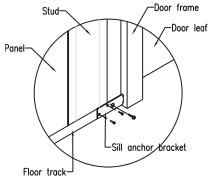

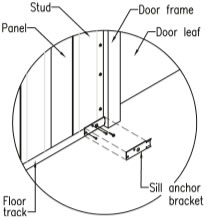

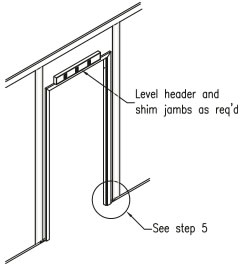

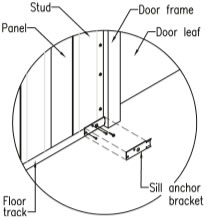

Step

4

Level door header and shim jambs as required. (Detail R)

Step 5 Use the sill anchor brackets to anchor jambs

to the floor track.

(Detail S)

|

|

|

|

|

|

|

|

|

|

|

|

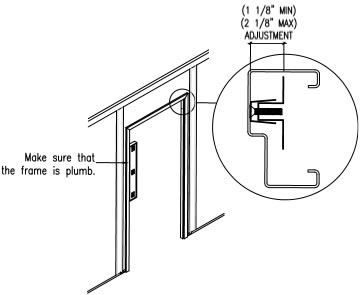

Installation

Note

|

|

|

|

|

|

|

|

|

|

|

|

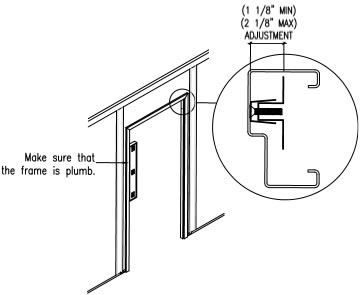

Make

sure that the frame is plumb. |

|

|

|

|

|

|

|

|

|

|

|

Step

6

Turn adjustment screw counterclockwise to secure frame.

Do not use these screws to plumb the frame. (Detail T) |

|

|

|

|

|

|

|

Detail

S

|

|

|

|

|

|

|

|

|

Detail

R

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

U

|

|

|

|

|

|

|

|

|

|

|

|

|

|

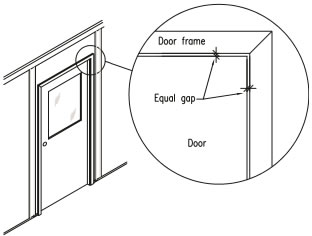

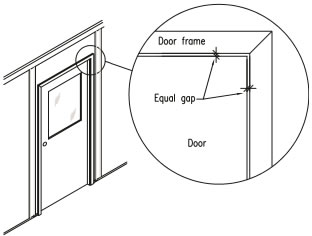

Step

7

If the frame is installed properly, there will be an equal gap

between the door and the frame. (Detail U) |

|

|

Detail

T

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

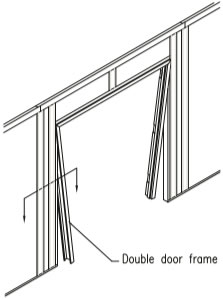

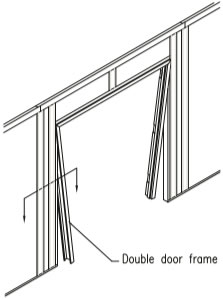

Double

Door Installation

|

|

|

|

|

|

|

|

|

|

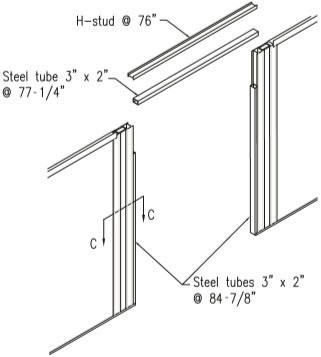

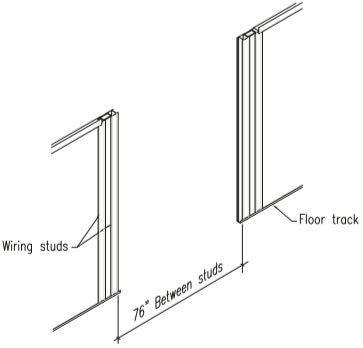

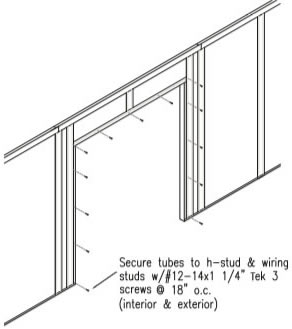

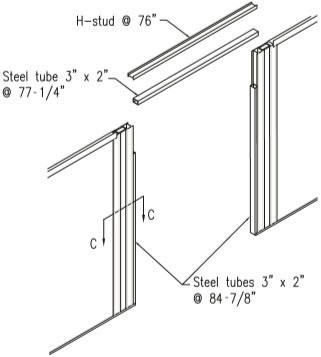

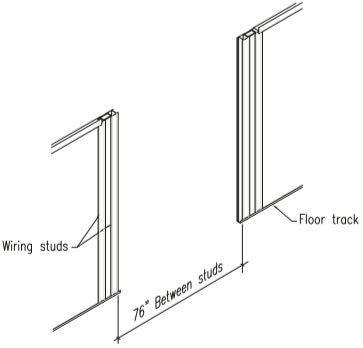

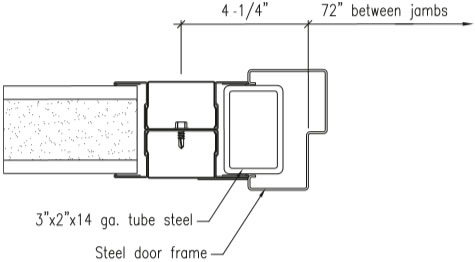

Walls

should be secure at this point. Check on this before installing

door.

The double door assembly is shipped knocked down and is not

pre-hung in a panel. Framing for the door opening

includes steel tubes for 3" walls and steel channels for

1-9/16", 4-5/8" and 6" walls. The door should

be installed

during the wall installation. The steel assembly framing should

be in place with the remainder of the wall. All studs

should be secured to the cornice mold before adjusting the frame.

Note: The material sizes indicated in the

following steps are for a 6'-0" x 7'-0" double door

in an 8'-0" wall system. Sizes will vary for other door

sizes and

wall heights. Refer to drawings.

Assure that studs on each side of the door are plumb and located

properly according to the layout. The distance

between studs should be 76". (Detail V)

Install 84-7/8" vertical tubes or channels into each stud.

(Detail X) Note: Channels are installed with the

open side towards the stud. |

|

|

|

|

|

|

|

|

|

|

|

Detail

W

|

|

|

|

|

Detail

V

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

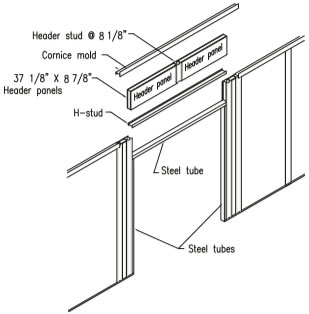

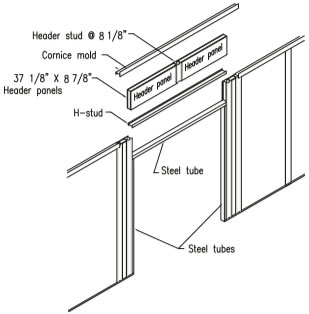

Set

77 1/4" tube or channel across opening to rest on vertical

supports. (Detail W) Place 76" H-stud on horizontal

tube or channel.

Install 37 1/8" x 12 7/8" header panels along with

the 12 1/8" header stud. Note that header stud will rest

on h-stud.

(Detail Y) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

X

|

|

|

|

|

|

|

|

|

|

|

|

Detail

Y

|

|

|

|

|

|

|

|

|

|

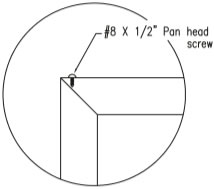

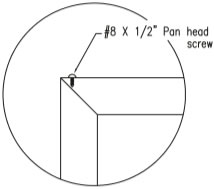

1)

Install cornice mold on top of wall, plumb studs and secure

studs to cornice mold.

2) Locate all frame parts before installing frame. Included

with the three (3) framing parts will be the following:

four (4) sill anchor brackets to be

installed at the bottom of the hinge jamb to secure the frame.

Six (6) 4-1/2" x

4-1/2" hinges, six (6) hinge

back-up plates to place between the hinge and door and four

(4) #8x1/2" pan head

screws to secure frame header to jambs.

3) Install sill anchor brackets into the bottom of the hinge

jambs.

4) Install three (3) door frame parts into opening making

sure that the mitered joint connects properly.

(Detail 4 & 5) Plumb each

jamb and level header. Secure jambs at floor using sill anchor

brackets. (Detail 1)

Tighten adjustment screw to hold door

frame plumb. Install door frame header screws in top of frame

using

#8x1/2" pan head screws. (Detail

2)

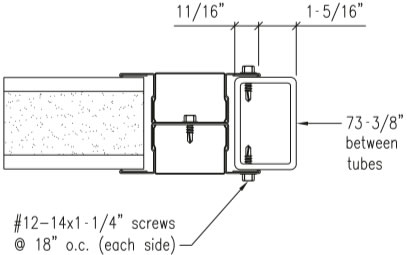

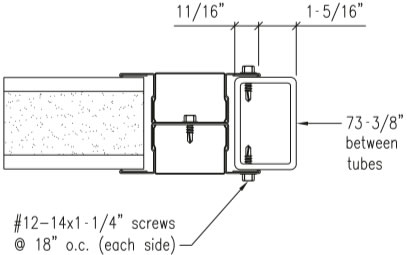

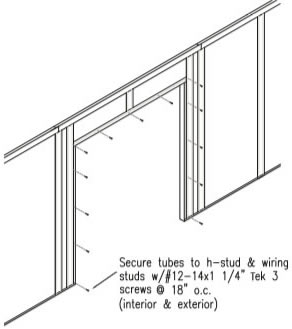

5) Secure studs to tubes by fastening through the leg of the

studs and h-stud with #12-14 x 1-1/4" Tek 3 screws.

This must be done at the corners of

the frame and at 18" o.c. on both sides of the door.

(Detail 3)

6) Install hinge butts: one-half mounts to frame and the other

half to the door. Make sure the hinge back-up plates

are installed between the hinges and

the door.

|

|

|

7)

Once the wall is rigid, hang the door onto the frame by meeting

hinge butts together and replacing hinge

pins.

8) Operate door to check fit. Doors should swing easily.

9) Install head and foot bolts on inactive door |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

1

|

|

Detail

2

|

|

|

Detail

3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

4

|

|

|

|

|

|

Detail

5

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dust

Cover Installation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

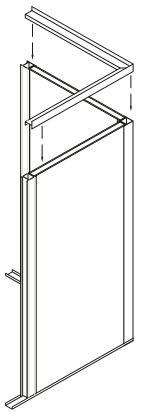

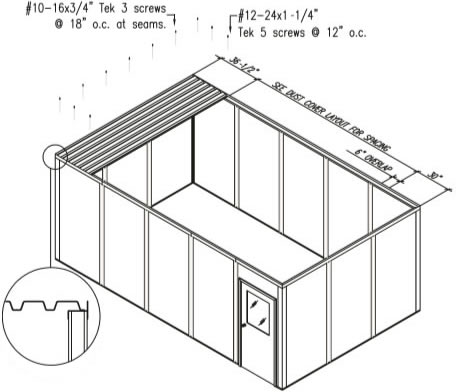

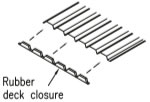

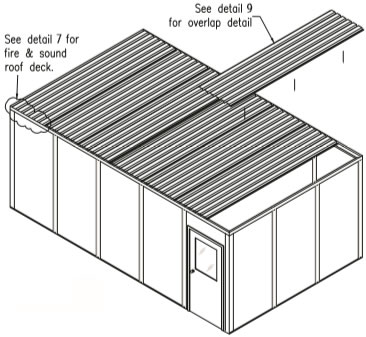

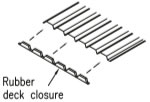

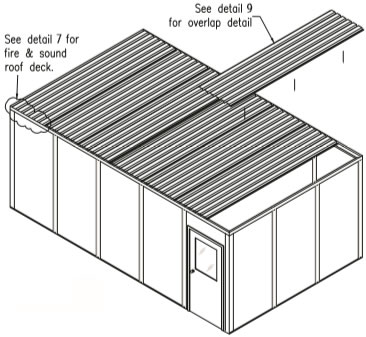

The

dust cover consists of metal decking and support beams, as required.

The standard decking is 22 gauge, 1-1/2"

type "B" deck, and is required to make the office

walls free-standing. The decking has a modified "V"

roll form

design. As such, it will grow or shrink in width during installation.

Care should be exercised to control the

dimensions while installing. All Fire & Sound buildings

come with a rubber deck closure to fill the corrugation

openings between deck and building. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note:

Unless the office has been specifically designed to have

a storage roof, it is not intended to hold the weight of a person

or storage. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

7

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

9

|

|

|

|

|

|

|

|

|

|

|

|

Detail

6

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

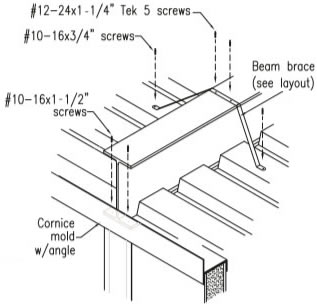

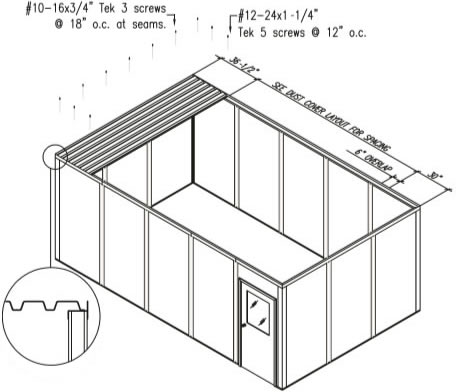

1)

Install the dust cover by placing the first piece of deck at

one end of the office, resting on the cornice mold.

Follow dust cover layout on building

plans. The edge without a return lip should be next to the outside

of the

building. (Detail 6)

2) Prior to screwing the dust cover down, insert the rubber

deck closure by tacking it between the dust cover and |

|

|

the

top of the cornice mold. (Detail 7) |

|

Detail

8

|

|

|

|

|

|

|

|

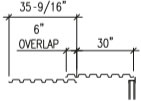

3)

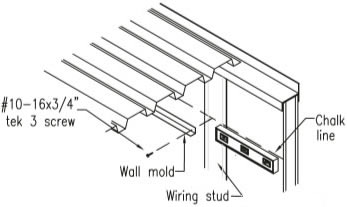

Secure decking to the cornice mold with #10-16 x

3/4" Tek 3 screws at 18" o.c.

along the seams and

with #12-24 x 1-1/4" Tek 5 screws

in every other

valley. (Detail 6)

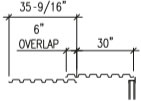

4) Make a mark on the cornice mold to locate the

placement of the next section of the

decking. This

dimension will vary between 35-3/8"

and 36-1/4".

5) Place the second piece of decking next to the first

piece with the edge overlapping the

return lip of the

first piece. Note: Be sure to

secure each piece.

6) Continue installing decking across the room as

instructed above to complete. (Detail

8) Overlapping

dust cover sections may be necessary.

(Detail 9)

Please refer to job drawings sent with

project. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Non-Load

Bearing Beams

|

|

|

|

|

|

|

|

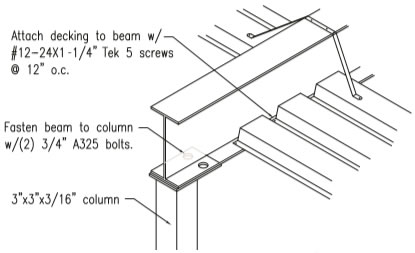

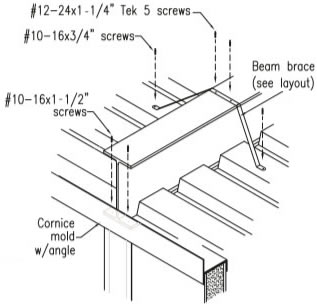

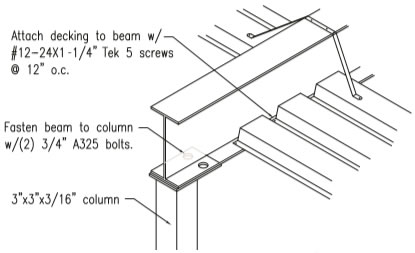

Place

support beams above the walls. Beams must be supported by

wall studs or steel columns at ends. Follow layout drawing

for proper beam placement.

Step 1 Secure ends of beam with #10-16 x 1-1/2"

Tek 3 screws into cornice mold at wall. (Detail 10)

Step 2 Fasten roof deck to the beam with #12-14 x 1-1/4"

Tek 5 screws at 12" o.c. To complete the deck installation,

refer to dust cover installation on previous page.

Step 3 Attach conduit beam braces to the beam top flange

and dust cover.

|

|

|

|

|

|

|

|

|

Detail

11

|

|

|

|

|

|

|

|

Installation

Note

|

|

|

|

|

|

|

Detail

10

|

|

Electrical

wiring should be done by a qualified electrician. |

|

|

|

|

|

|

|

Electrical

|

|

|

|

|

|

|

|

|

|

|

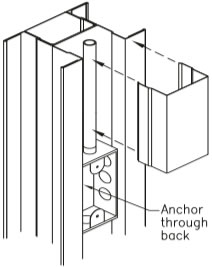

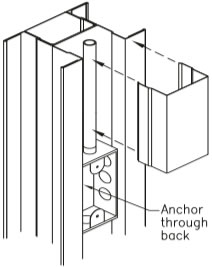

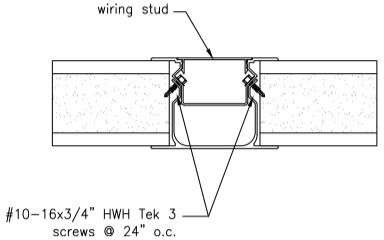

1)

Install handy boxes into studs at desired locations with a

#10-16 x 3/4"

Tek 3 screw. Fasten through the back

of the box (Detail 12) Typical

locations are 12"-18" above

the floor for duplex outlets and 48" to 54"

AFF for switches and single outlets.

2) Cut conduit as needed. Conduit should terminate just above

ceiling

level.

3) Install stud cover plates by cutting to size above and

below each handy

box location. Cover plates should

also terminate just above the ceiling

to allow for wiring across the ceiling.

4) If installing a bean onto a column, follow steps 1-3 when

securing top

plate of columns. (Detail 11)

|

|

|

|

|

|

|

Detail

12

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Acoustical

Ceiling Installation

|

|

|

|

|

|

|

|

|

|

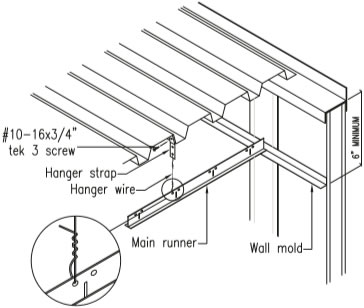

Determine

the required finished ceiling height for the room. For ease

of installation and proper light fixture

clearance, the ceiling should be a minimum of 6" below

the underside of the deck (6-1/2" if an exhaust fan will

be

installed). Most building codes require a minimum clearance

of 7'-6" from the floor to ceiling.

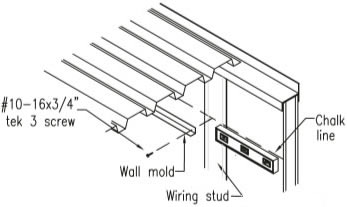

1) Snap a chalk line 1" above the required ceiling height

around the perimeter of the room. This line should be

checked for level before snapping

the string. (Detail 14).

2) Cut wall mold as required and position so that top of angle

is even with the chalk line. Secure the wall angle to

studs and corners with #10-16x3/4"

tek 3 screws. Proceed around the room. Wall mold may be overlapped

or

miter cut at corner joints.

3) Mark the location of main runners by putting marks above

the wall mold. Tie a string around the wall mold and

stretch it across the room near the

position of the main runner. This will provide a reference

line to install hanger

straps and wires.

|

|

|

|

|

|

|

|

|

|

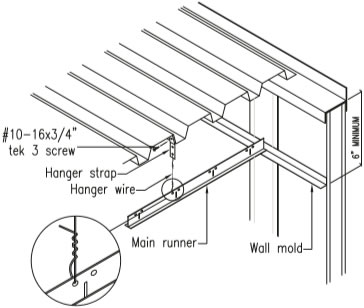

4) Attach wire hanger straps to the bottom of the dust

cover at 4' o.c. Along each main runner.

(Detail 15)

Make certain that a hanger wire is located

at each

corner where a lay-in light fixture

will be. Cut hanger

wire as needed, usually allowing an

additional 6" at

each end to twist in place. Install

wire through the

hanger strap; bending wire back down

and wrapping

tightly 3-4 twists. (Detail 16) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

16

|

Detail

15

|

|

|

|

|

|

|

|

|

Detail

14

|

|

|

|

|

|

|

|

|

|

|

|

|

|

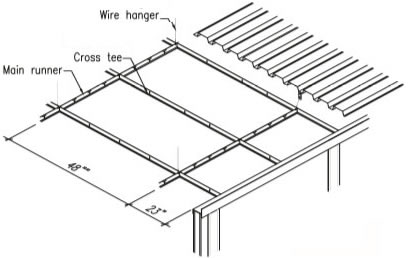

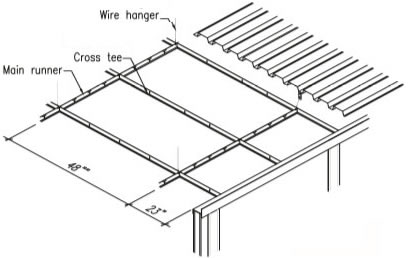

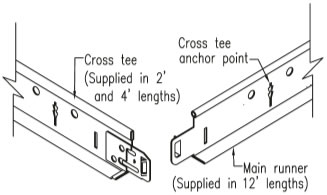

The

ceiling grid consists of two major components, 12' main runners

and 4' cross tees. (Detail 17) The main

runners typically run the longer length of the room. Closely

follow the layout drawing provided to assure easy

installation and proper material quantities.

5) Install 12' main runners at locations shown on drawing using

hanger wire provided. Be certain that 4' cross tee

anchor points correspond to the ceiling

plan. Allow the main runner to fully rest on the wall mold.

6) The ceiling wire may then be attached to the main runner.

Be sure to wrap the wire around itself at least 3 times.

(Detail 16) Care should be taken

to install the main runner straight and level. Continue until

all main runners are

installed.

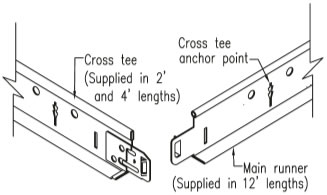

7) Install cross tees at points indicated on the drawings by

inserting tabs into anchor points. Trim pieces at wall, as

required, for tee to rest fully on

wall mold. To strengthen the grid the tees may be secured to

the wall mold with

pop-rivets (not supplied). Intersections

of cross tees and main runner must form a 90-degree corner.

(Detail 18)

8) Place light fixtures into grid at locations indicated on

drawing. Make certain that a hanger wire is located at each

corner where a lay-in light fixture

will be.

9) Cutting ceiling panels may be accomplished with the panels

facing up using a saw or a very sharp fiberboard

knife. Measure and cut each of the border

panels individually.

10) Lay-in panels are installed by carefully tilting the panel

to fit through grid opening then resting the panel on

cross tee and main runner flanges. Exercise

care when handling ceiling panels to avoid marring the surface.

Handle edges of panels, keeping fingers

off the finished side of the panel as much as possible. Clean

hands are

necessary for a clean job. It may be

necessary to use the left over portion of the tile for other

cut pieces. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detail

17

|

|

|

|

|

|

|

|

|

|

Detail

18

|

|

|

|

|

|

|

|

In-Plant

Office Fastener Guide

|

|

|

|

Part

No.

Size

|

Sample

Image

|

Description,

Uses & Quantities

|

|

FAS87630

#10-16x3/4"

|

|

Hex

Washer Head Tek 3

• Assemble studs (8 per 8', 10 per 9', 12 per

10', etc.)

• Secure studs, corners and wall starter to

floor track and cornice mold (3 per

stud)

• Fasten roof deck at seams (18" o/c at

seams)

• Fasten beam braces to deck (2 per brace)

• Fasten ceiling hanger straps to deck (1 per

strap) |

|

FAS35790

1/4"-20x7/8"

|

|

Phillips

Flat Head

• Assemble 3" corner post (4 for 8', 5 for 9',

6 for 10', etc.) |

|

FAS10-16CRIMP

#10-16x3/4"

|

|

Hex

Head Type 1 Crimptite Tek 2

• Assemble studs (8 per 8', 9 per 9', etc.) |

|

FAS87780

#10-16x1 1/2"

|

|

Hex

Washer Head Tek 3

• Fasten beams to cornice mold (4 per recessed

beam plate, 2 per beam saddle,

4 per non-load bearing beam) |

|

FAS87845

#12-24x1 1/4"

|

|

Hex

Washer Head Tek 5

• Fasten roof deck to beams (12" o/c at

beam)

• Fasten beam braces to beams (2 per brace)

• Fasten roof deck to cornice mold (12" o/c

at deck ends) |

|

FAS87849

#12-24x2 1/2"

|

|

Phillips

Flat Head Tek 3

• Fasten wood support boards to cornice

mold (2 per board) |

|

FAS87840

#12-14x1 1/4"

|

|

Hex

Washer Head Tek 3

• Fasten shear panels (12" o/c all around

shear panel and 8 per bracket)

• Fasten studs to double door tubes (30 per

door) |

|

FASDWS08108

#8 x 1 1/2"

|

|

Phillips

Bugle Head Drywall Screw

• Fasten 3/4" plywood/OSB to roof deck

(45 per sheet) |

|

FAS87580

#10-16x5/8"

|

|

Phillips

Pan Head Tek 3

• Fasten vinyl base to wall (7 per pc. of

vinyl base and 2 per corner) |

|

FAS166310

|

|

HVAC

Screw Packet

• 1 Pkg/per Unit |

|

|

|

|

|

|

Cleaning

& Maintenance Protocol: Modular Wall Systems

|

|

|

|

|

|

Wipe

the panels, studs and extrusions with an owner approved alcohol

wipe or mild soap and water with a damp

sponge or rag. If any chemicals are to be utilized, spot check

with extra materials or in an inconspicuous place

prior to use to insure that the finish of the wall system

is not damaged.

Upon request, we can provide touchup paint, vinyl facings

and replacement material based on your requirements.

|

|

|

|

|

|

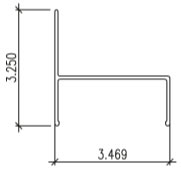

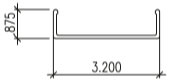

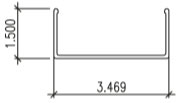

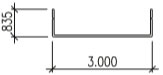

Aluminum

Wall System

|

|

|

|

|

|

|

|

|

The

aluminum version installs in the same manner as the modular

office system.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard

Quick-Ship Modular Offices, Modular Offices, Inplant Building,

Inplant Buildings, Inplant Modular Office, Inplant

Modular Offices, Inplant Office, Inplant Offices, Partition

Wall Systems, Prefab Office, Prefab Offices, Inplant Modular

Offices,

and Prefabricated Offices from your complete source for material

handling equipment.

|

Back

to Product Category |

|

|