|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

STEEL

BAR GRATING

|

STAINLESS

STEEL GRATING

|

|

|

|

|

|

|

|

|

When

caustic atmospheres are encountered, or when

corrosion resistance and/or minimum carbide

precipitation are essential considerations, stainless

steel grating is the answer. The longer lasting

capabilities of stainless steel under these special

conditions make it an economical selection over the

long term. |

|

Shot

blasting or wire brushing should be avoided since

these operations can cause iron contamination which,

if not removed, will cause rusting and discoloration of

the surface. Such contamination can be removed by

passivation. Electro-polishing leaves a passive surface.

The swage-locked and presslocked processes will

not show discoloration due to welding. |

|

|

|

|

|

|

|

|

It

is ideal for use in food processing areas, breweries,

bottling plants, dairies and meat packing plants. Stainless

steel can also be used in power plants, sewage treatment

plants, pumping stations and hydrocarbon processing

facilities where various caustic environments are normal.

It also has application in shipboard and building industries

where saline solutions or atmospheres are present. |

|

|

|

|

|

|

|

|

Unless

otherwise specified, stainless steel grating

shall have a mill finish as fabricated. “As fabricated”

means as fabricated in our shop without a subsequent

finishing operation. Stainless steel will show some

discoloration around the joints due to welding

Finishes available to remove discoloration include

sand blasting and electro-polishing, the latter being

used where bright finish is desired. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| CHEMICAL

COMPOSITION |

Type

304 alloys resist most oxidizing acids and can withstand all ordinary rusting.

They are immune to foodstuffs, sterilizing solutions

most of the organic chemicals and dyestuffs, and a wide variety of inorganic

chemicals. This grade should be considered for use unless

some special mechanical, physical or fabricating characteristic is required. |

| Alloy |

Carbon

(max. %) |

Manganese

(max. %) |

Silicon

(max. %) |

Chromium

(%range) |

Phosphorus

(max. %) |

Sulfur

(max %) |

Nickel

(% range) |

Nitrogen

(max. %) |

| 304 |

0.08 |

2.0 |

0.75 |

18-20 |

0.045 |

0.030 |

8-10.5 |

0.10 |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

|

|

PRICING

FOR STAINLESS STEEL GRATING |

| Cut

to size panels, please contact us. |

Click

on desired panel size: 2' x 20', 3'

x 20', 3' x 24' |

3'

X 20' SMOOTH SURFACE PANELS (non serrated) |

|

|

3'

X 20' SERRATED PANELS |

| Model No. |

Bar Size

D x W (in.) |

Bearing

Bar Spacing |

Cross

Bar Spacing |

Wt.

(lbs) |

Stainless

Steel

Price |

|

1 x 3/16 |

1 3/16" |

4" |

441 |

$13,003 |

|

1 1/4 x 3/16 |

1 3/16" |

4" |

542 |

$15,564 |

|

1 1/2 x 3/16 |

1 3/16" |

4" |

656 |

$18,141 |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

|

|

3'

X 24' SMOOTH SURFACE PANELS (non serrated) |

back

to top |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

|

|

2'

X 20' SMOOTH SURFACE PANELS (non serrated) |

|

|

|

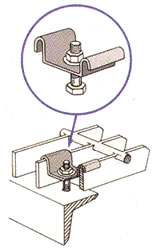

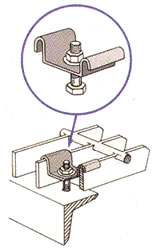

| Bar

Grating Clip |

|

|

|

|

|

|

Hold grating sections securely in place Hold grating sections securely in place |

|

|

|

|

|

Removable - reusable Removable - reusable |

|

|

|

|

|

Clip only - does not include nuts, bolts or Clip only - does not include nuts, bolts or

washers |

|

|

|

|

|

| Use

with 19W4-304SS |

|

|

|

|

|

| CLIP-19W4-304SS ............................ $4.44 ea. |

|

|

|

|

|

|

|

|

|

| LOAD

& DEFLECTION TABLE |

|

SPAN (Length of Bearing Bar) |

Bar

Size |

Model

No. |

Apprx.

Wgt.

psf |

Sec. Mode

Per Ft.

of Width |

|

24" |

30" |

36" |

42" |

48" |

54" |

60" |

66" |

72" |

78" |

84" |

96" |

108" |

3/4" x

1/8" |

19-4-W-SS |

3.9 |

0.118 |

U |

395 |

253 |

175 |

129 |

99 |

78 |

- |

|

|

|

|

|

|

| D |

0.114 |

0.179 |

0.257 |

0.350 |

0.457 |

0.579 |

- |

- |

- |

- |

- |

- |

- |

| C |

395 |

316 |

263 |

226 |

197 |

175 |

- |

- |

- |

- |

- |

- |

- |

| D |

0.091 |

0.143 |

0.206 |

0.280 |

0.366 |

0.463 |

- |

- |

- |

- |

- |

- |

- |

3/4" x

3/16" |

19-4-W-SS |

5.6 |

0.178 |

U |

592 |

379 |

263 |

193 |

148 |

117 |

- |

- |

- |

- |

- |

- |

- |

| D |

0.114 |

0.179 |

0.257 |

0.350 |

0.457 |

0.579 |

- |

- |

- |

- |

- |

- |

- |

| C |

592 |

474 |

395 |

338 |

296 |

263 |

- |

- |

- |

- |

- |

- |

- |

| D |

0.091 |

0.143 |

0.206 |

0.280 |

0.366 |

0.463 |

- |

- |

- |

- |

- |

- |

- |

1" x 1/8" |

19-4-W-SS |

5.0 |

0.211 |

U |

702 |

449 |

312 |

229 |

175 |

139 |

112 |

93 |

- |

- |

- |

- |

- |

| D |

0.086 |

0.134 |

0.193 |

0.263 |

0.343 |

0.434 |

0.536 |

0.648 |

- |

- |

- |

- |

- |

| C |

702 |

561 |

468 |

401 |

351 |

312 |

281 |

255 |

- |

- |

- |

- |

- |

| D |

0.069 |

0.107 |

0.154 |

0.210 |

0.274 |

0.347 |

0.429 |

0.519 |

- |

- |

- |

- |

- |

1" x 3/16" |

19-4-W-SS |

7.2 |

0.316 |

U |

1053 |

674 |

468 |

344 |

263 |

208 |

168 |

139 |

- |

- |

- |

- |

- |

| D |

0.086 |

0.134 |

0.193 |

0.263 |

0.343 |

0.434 |

0.536 |

0.648 |

- |

- |

- |

- |

- |

| C |

1053 |

842 |

702 |

602 |

526 |

468 |

421 |

383 |

- |

- |

- |

- |

- |

| D |

0.069 |

0.107 |

0.154 |

0.210 |

0.274 |

0.347 |

0.429 |

0.519 |

- |

- |

- |

- |

- |

1-1/4"

x 1/8" |

19-4-W-SS |

6.1 |

0.329 |

U |

1096 |

702 |

487 |

358 |

274 |

217 |

175 |

145 |

122 |

104 |

90 |

- |

- |

| D |

0.069 |

0.107 |

0.154 |

0.210 |

0.274 |

0.347 |

0.429 |

0.519 |

0.617 |

0.724 |

0.840 |

- |

- |

| C |

1096 |

877 |

731 |

627 |

548 |

487 |

439 |

399 |

365 |

337 |

313 |

- |

- |

| D |

0.055 |

0.086 |

0.123 |

0.168 |

0.219 |

0.278 |

0.343 |

0.415 |

0.494 |

0.579 |

0.672 |

- |

- |

1-1/4"

x 3/16" |

19-4-W-SS |

8.9 |

0.493 |

U |

1645 |

1053 |

731 |

537 |

411 |

325 |

263 |

217 |

183 |

156 |

134 |

- |

- |

| D |

0.069 |

0.107 |

0.154 |

0.210 |

0.274 |

0.347 |

0.429 |

0.519 |

0.617 |

0.724 |

0.840 |

- |

- |

| C |

1645 |

1316 |

1096 |

940 |

822 |

731 |

658 |

598 |

548 |

506 |

470 |

- |

- |

| D |

0.055 |

0.086 |

0.123 |

0.168 |

0.219 |

0.278 |

0.343 |

0.415 |

0.494 |

0.579 |

0.672 |

- |

- |

1-1/2"

x 1/8" |

19-4-W-SS |

7.2 |

0.474 |

U |

1579 |

1011 |

702 |

516 |

395 |

312 |

253 |

209 |

175 |

149 |

129 |

99 |

78 |

| D |

0.057 |

0.089 |

0.129 |

0.175 |

0.229 |

0.289 |

0.357 |

0.432 |

0.514 |

0.604 |

0.700 |

0.914 |

1.157 |

| C |

1579 |

1263 |

1053 |

902 |

789 |

702 |

632 |

574 |

526 |

486 |

451 |

395 |

351 |

| D |

0.046 |

0.071 |

0.103 |

0.140 |

0.183 |

0.231 |

0.286 |

0.346 |

0.411 |

0.483 |

0.560 |

0.731 |

0.926 |

1-1/2"

x 3/16" |

19-4-W-SS |

10.5 |

0.711 |

U |

2368 |

1516 |

1053 |

773 |

592 |

468 |

379 |

313 |

263 |

224 |

193 |

148 |

117 |

| D |

0.057 |

0.089 |

0.129 |

0.175 |

0.229 |

0.289 |

0.357 |

0.432 |

0.514 |

0.604 |

0.700 |

0.914 |

1.157 |

| C |

2368 |

1895 |

1579 |

1353 |

1184 |

1053 |

947 |

861 |

789 |

729 |

677 |

592 |

526 |

| D |

0.046 |

0.071 |

0.103 |

0.140 |

0.183 |

0.231 |

0.286 |

0.346 |

0.411 |

0.483 |

0.560 |

0.731 |

0.926 |

1-3/4"

x 3/16" |

19-4-W-SS |

12.2 |

0.967 |

U |

3224 |

2063 |

1433 |

1053 |

806 |

637 |

516 |

426 |

358 |

305 |

263 |

201 |

159 |

| D |

0.049 |

0.077 |

0.110 |

0.150 |

0.196 |

0.248 |

0.306 |

0.370 |

0.441 |

0.517 |

0.600 |

0.784 |

0.992 |

| C |

3224 |

2579 |

2149 |

1842 |

1612 |

1433 |

1289 |

1172 |

1075 |

992 |

921 |

806 |

716 |

| D |

0.039 |

0.061 |

0.088 |

0.120 |

0.157 |

0.198 |

0.245 |

0.296 |

0.353 |

0.414 |

0.480 |

0.627 |

0.793 |

2" x 3/16" |

19-4-W-SS |

13.9 |

1.263 |

U |

4211 |

2695 |

1871 |

1375 |

1053 |

832 |

674 |

557 |

468 |

399 |

344 |

263 |

208 |

| D |

0.043 |

0.067 |

0.096 |

0.131 |

0.171 |

0.217 |

0.268 |

0.324 |

0.386 |

0.453 |

0.525 |

0.686 |

0.868 |

| C |

4211 |

3368 |

2807 |

2406 |

2105 |

1871 |

1684 |

1531 |

1404 |

1296 |

1203 |

1053 |

936 |

| D |

0.034 |

0.054 |

0.077 |

0.105 |

0.137 |

0.174 |

0.214 |

0.259 |

0.309 |

0.362 |

0.420 |

0.549 |

0.694 |

2-1/4"

x 3/16" |

19-4-W-SS |

15.5 |

1.599 |

U |

5329 |

3411 |

2368 |

1740 |

1332 |

1053 |

853 |

705 |

592 |

505 |

435 |

333 |

263 |

| D |

0.038 |

0.060 |

0.086 |

0.117 |

0.152 |

0.193 |

0.238 |

0.288 |

0.343 |

0.402 |

0.467 |

0.610 |

0.771 |

| C |

5329 |

4263 |

3553 |

3045 |

2664 |

2368 |

2132 |

1938 |

1776 |

1640 |

1523 |

1332 |

1184 |

| D |

0.030 |

0.048 |

0.069 |

0.093 |

0.122 |

0.154 |

0.190 |

0.230 |

0.274 |

0.322 |

0.373 |

0.488 |

0.617 |

2-1/2"

x 3/16" |

19-4-W-SS |

17.2 |

1.974 |

U |

6579 |

4211 |

2924 |

2148 |

1645 |

1300 |

1053 |

870 |

731 |

623 |

537 |

411 |

325 |

| D |

0.034 |

0.054 |

0.077 |

0.105 |

0.137 |

0.174 |

0.214 |

0.259 |

0.309 |

0.362 |

0.420 |

0.549 |

0.694 |

| C |

6579 |

5263 |

4386 |

3759 |

3289 |

2924 |

2632 |

2392 |

2193 |

2024 |

1880 |

1645 |

1462 |

| D |

0.027 |

0.043 |

0.062 |

0.084 |

0.110 |

0.139 |

0.171 |

0.207 |

0.247 |

0.290 |

0.336 |

0.439 |

0.555 |

|

| Note:

For gratings with other than 1-3/16" bearing bar spacing, proportionate

conversion factors apply. |

|

19S

PANEL WIDTH (inches) Note: S-Stainless Welded cross rods

may extend 1/8" each side. Panel widths do not include these

extensions. |

| No. of Bars |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 1/8" Bar |

1 5/16 |

2 1/2 |

3 11/16 |

4 7/8 |

6 1/16 |

7 1/4 |

8 7/16 |

9 5/8 |

10 13/16 |

12 |

13 3/16 |

14 3/8 |

15 9/16 |

16 3/4 |

17 15/16 |

| 3/16" Bar |

1 3/8 |

2 9/16 |

3 3/4 |

4 15/16 |

6 1/8 |

7 5/16 |

8 1/2 |

9 11/16 |

10 7/8 |

12 1/16 |

13 1/4 |

14 7/16 |

15 5/8 |

16 13/16 |

18 |

| No. of Bars |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

28 |

29 |

30 |

31 |

| 1/8" Bar |

19 1/8 |

20 5/16 |

21 1/2 |

22 11/16 |

23 7/8 |

25 1/16 |

26 1/4 |

27 7/16 |

28 5/8 |

29 13/16 |

31 |

32 3/16 |

33 3/8 |

34 9/16 |

35 3/4 |

| 3/16"

Bar |

19 3/16 |

20 3/8 |

21 9/16 |

22 3/4 |

23 15/16 |

25 1/8 |

26 5/16 |

27 1/2 |

28 11/16 |

29 7/8 |

31 1/16 |

32 1/4 |

33 7/16 |

34 5/8 |

35 13/16 |

|

|

Steel Bar Grating, Stainless

Steel Grating, Floor Grating, Corrosion Resistance, Bar Grating Clip,

and 19W4-304SS from your

complete source for material handling equipment. |

Back

to Product Category |

|

|