|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

ROUND

CABLE AND AIR HOSE

FESTOON SYSTEMS |

|

|

|

SEE BELOW

FOR INSTALLATION INSTRUCTION FOR WIRE SUPPORTED SYSTEMS |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

PRICES |

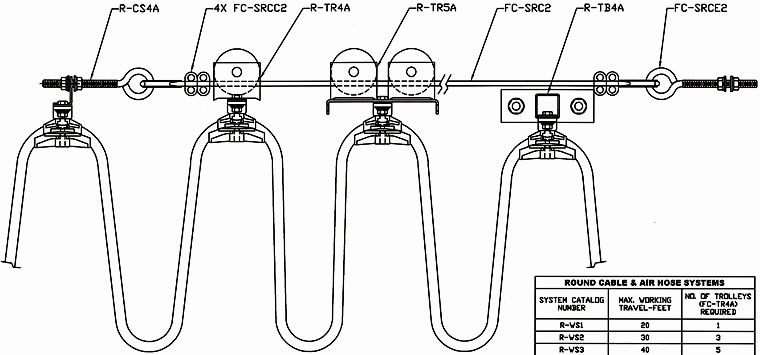

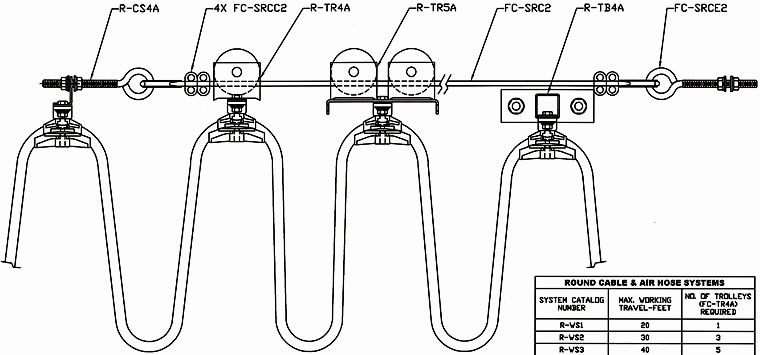

System

Model # |

Max.

Working Travel-Feet |

No.

of Trolleys (R-TR4A) Required |

Prices |

|

20 |

1 |

$208.00 |

|

30 |

3 |

$286.00 |

|

40 |

5 |

$363.00 |

|

|

| Each

round cable and air hose system includes the parts in the following table.

Order cable and connectors separately. |

Index

# |

Model

# |

Component |

1 |

R-CS4A |

End

Clamp Assembly |

2 |

FC-SRCE2 |

Eye

Bolt and Thimble |

3 |

FC-SRCC2 |

U-Clamp,

4 required |

4 |

R-TR4A |

Single

Wheel Trolley |

5 |

FC-SRC2 |

Nylon

Coated Wire Rope 1/4" dia. |

6 |

R-TB5A |

Two

Wheel Lead Trolley |

6 |

R-TB4A |

Tow

Arm Assembly |

|

|

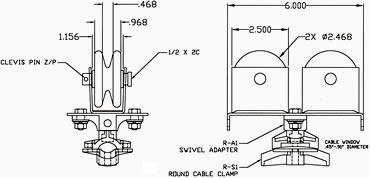

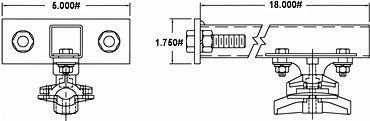

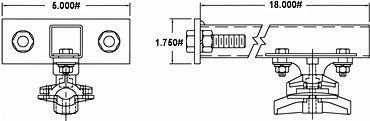

R-WS1 |

|

|

|

|

|

|

|

R-CS4A |

|

FC-SRCE2 |

|

|

|

|

|

R-TR4A |

|

|

|

|

|

R-TR5A |

|

|

|

|

|

|

|

R-TB4A |

|

|

|

|

|

|

|

|

INSTALLATION

INSTRUCTIONS FOR WIRE SUPPORTED SYSTEMS |

|

|

|

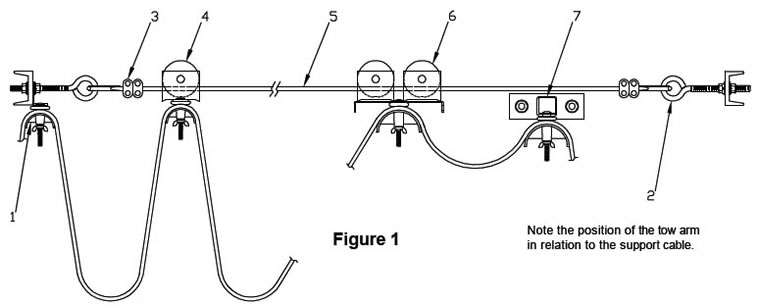

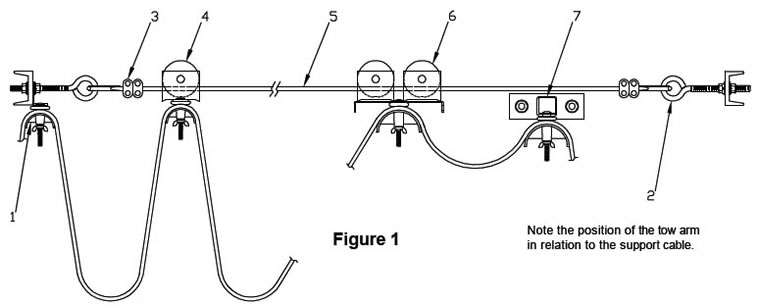

Figure

1 illustrates a typical stretched wire supported festoon cable system. Component

part numbers for all types of

the wire supported systems are listed below. |

|

|

|

|

|

|

Index

# |

Model

# |

Component |

Index

# |

Model

# |

Component |

1 |

FC-CS4 |

End

Clamp Assembly |

5 |

FS-SRC2 |

Nylon

Coated Wire Rope, 1/4" dia. |

2 |

FC-SRCE2 |

Eye

Bolt and Thimble |

|

3 |

FC-SRCC2 |

U-Clamp,

4 required |

6 |

FS-TR5 |

Two-Wheel

Lead Trolley |

4 |

FC-TR4 |

Single

Wheel Trolley |

7 |

FC-TB4 |

Tow

Arm Assembly |

|

|

|

Note

that the support brackets which are normally mounted on each end of the

crane bridge to be electrified are not

included in the system but are supplied by the purchaser. These brackets

must be adequate to support the cable tension

applied when the adjustment is made to eliminate the cable sag caused by

the weight of the trolleys and festoon cable.

Normally this will be 1/4" thick angle or channel iron adequately fastened. |

|

|

The

position of the cable on the bridge is determined by the placement of the

tow arm assembly. The tow arm must

located just under the cable to provide for pushing back on the trolleys

when returning to the storage end of the system.

Be sure that a suitable place is found to install the tow arm and then place

the cable just above the tow arm. It will be

necessary to drill a hole in each support bracket for the 3/8" eye

bolts which will hold the cable ends. |

|

|

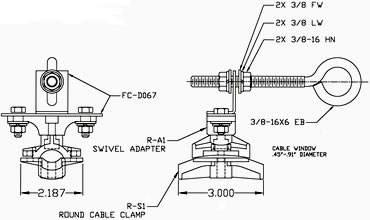

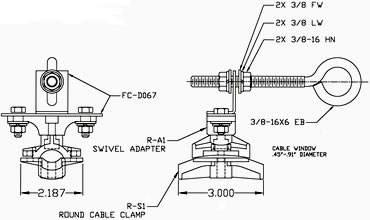

At

the end nearest the junction box where the cable connection is to be made,

install the FC-CS4 end clamp assembly.

(R-CS4A for round cable) The end clamp assembly has an eye bolt for one

end of the support cable. Feed the trolleys

onto the support cable and tie them near the end clamp until it is time

for a running test. Install the FC-SRCE2 eye bolt

and thimble at the opposite end. Draw the 1/4" nylon coated cable through

the eye bolt at each end and clamp the end

of the cable loop with the FC-SRCC2 U-clamps (2 at each end). Tighten the

nuts on the U-clamps to 50 inch-pounds. |

|

|

Adjust

the outside tightening nut on each of the eye bolts until adequate tension

is applied. To test for adequate tension,

first run the trolleys to the storage end so they are not weighting on the

cable. At the center of the system pull down on

the cable. If you can pull down more than 1" on a 20 to 60 ft. cable,

keep tightening until it does not exceed that amount.

The breaking strength of 1/4" nylon covered cable is 4,200#. Then tighten

the inside locking nut on the eye bolts at

each end of the system. |

|

|

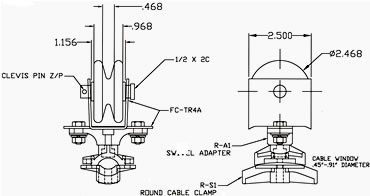

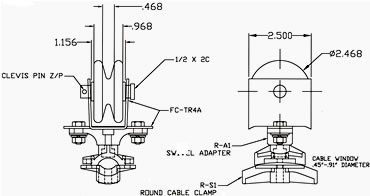

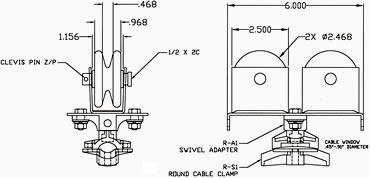

Untie

the trolleys and feed the festoon cable through the saddles until the proper

amount for trolley spacing on the

system is achieved. Tighten the saddle bolts to hold the cable(s) in place

and then run the system back and forth to

see that all trolleys run freely. |

|

|

| Then

apply power to the system and check through several cycles at slow speed

to check under operating conditions. |

|

|

Round Cable and Air Hose

Festoon System, Wire Supported Systems, Slide Wire Systems, Wheel Trolley

Systems, Industrial Festooning

Systems, Festoon Cable Systems, Pendant Control, Duct-O-Wire, Flat Cable,

Flat Cables, and C-Track from your complete source

for material handling equipment. |

Back

to Product Category |

|

|