|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

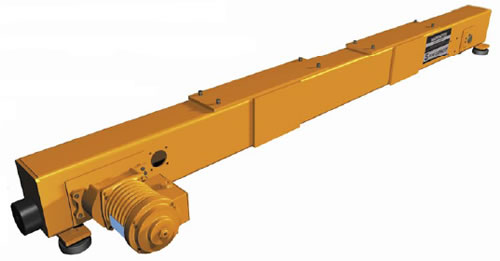

MTM—DOUBLE

GIRDER MAX-E-LIFT

|

Top

Running Motorized End Trucks

|

|

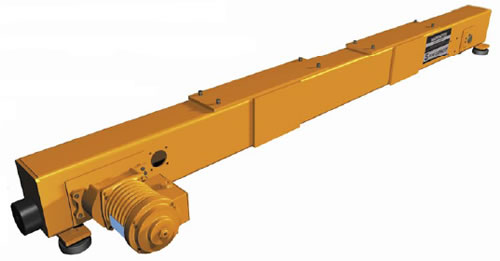

For

a compact, double girder configuration with all the benefits of the TM top

running motorized single girder design,

go with our MTM end trucks. Along with a full range of features, end truck

kits include: two trucks; two sealed,

totally enclosed non-ventilated (TENV) motors with adjustable DC brakes;

two helical gear reducers; rubber

bumpers; and bridge beam fastener set. All trucks are fully painted. Bridge

fabrication prints are also included. As

a member of Crane Manufacturers Association of America (CMAA), we build

MTM trucks to meet current industry

and regulatory codes. |

|

|

|

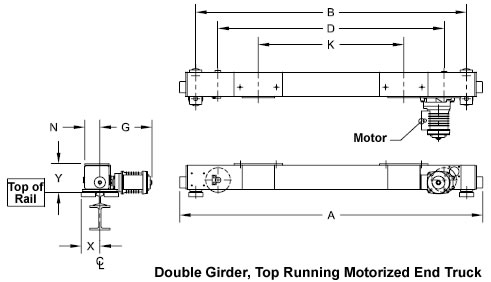

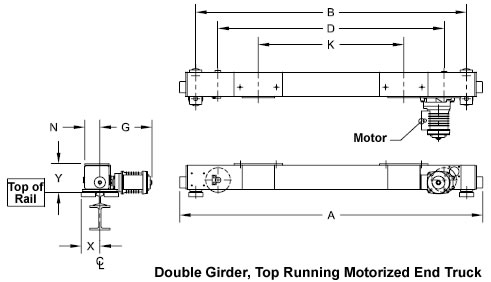

MTM -

MAX-E-LIFT TOP RUNNING MOTORIZED END TRUCK - DIMENSIONS |

Cap.

(Tons) |

Max.

Span

(ft.) |

End Truck

Product Code |

Wheel

Dia. (in) |

Sug.

Min.

Runway

Rail

(ASCE#) |

A

Overall

Length

(in) |

B

Roller

Base

(in) |

D

Wheel

Base (in) |

K

Beam

Gauge

(in) |

N

Runway

Ctr. Line

to Outer

Edge of ET

(in) |

X*

Width

Beyond

Span (in) |

Y

Top of

Rail to

Top of

End

Truck

(in) |

G

Motor

(in) |

| 1 |

35 |

MTML/S/H/D-3-0135 |

3.74 |

30 |

72 |

64 |

54 |

36 |

2.1 |

4.6 |

7.1 |

12.7 (L/S)

13.5 (H)

14.0 (D) |

| 60 |

MTML/S/H/D-3-0160 |

111 |

103 |

93 |

| 3 |

35 |

MTML/S/H/D-3-0335 |

6.10 |

75 |

67 |

56 |

3.8 |

13.0 (L/S)

13.4 (H)

14.3 (D) |

| 60 |

MTML/S/H/D-3-0360 |

40 |

112 |

104 |

93 |

| 5 |

35 |

MTML/S/H/D-3-0535 |

75 |

67 |

56 |

4.7 |

9.2 |

| 60 |

MTML/S/H/D-3-0560 |

8.27 |

112 |

103 |

87 |

3.5 |

9.3 |

15.0 (L/S/D)

15.4 (H) |

| 10 |

35 |

MTML/S/H/D-3-1035 |

9.84 |

60 |

93 |

83 |

67 |

48 |

5.3 |

6.3 |

11.3 |

17.4 (L/S/D)

18.7 (H) |

| 60 |

MTML/S/H/D-3-1060 |

113 |

103 |

87 |

|

| *Based

on suggested minimum runway rail. |

|

|

|

|

|

|

|

MTM

— MAX-E-LIFT TOP RUNNING MOTORIZED END TRUCK —

SPECIFICATIONS |

End Truck

Product Code |

Speed

Codes L and S |

Speed

Code H |

Speed

Code D |

End

Truck

Weight

(lbs/pr) |

One

Motor Per End Truck

3 Phase 60 Hz |

One

Motor Per End Truck

3 Phase 60 Hz |

One

Motor Per End Truck

3 Phase 60 Hz |

Output

(Hp) |

Rated Current

(amps ea.) |

Output

(Hp) |

Rated Current

(amps ea.) |

Output

(Hp) |

Rated Current

(amps ea.) |

| @230V |

@460V |

@230V |

@460V |

@230V |

@460V |

| MTML/S/H/D-3-0135 |

0.33 |

1.6 |

1.0 |

0.5 |

2.1 |

1.3 |

0.33/0.08 |

1.6/1.1 |

0.9/0.8 |

340 |

| MTML/S/H/D-3-0160 |

441 |

| MTML/S/H/D-3-0335 |

526 |

| MTML/S/H/D-3-0360 |

647 |

| MTML/S/H/D-3-0535 |

648 |

| MTML/S/H/D-3-0560 |

0.5 |

2.1 |

1.3 |

1.0 |

3.3 |

2.0 |

0.5/0.13 |

2.0/1.5 |

1.2/0.9 |

818 |

| MTML/S/H/D-3-1035 |

1.0 |

3.3 |

2.0 |

2.0 |

5.8 |

3.1 |

1.0/0.25 |

3.7/2.1 |

2.3/1.4 |

1105 |

| MTML/S/H/D-3-1060 |

1201 |

|

|

|

|

|

| Speed

Code |

|

Product

Code Derivation - example: MTML-3-0135 |

|

L

- Designates 40 ft/min

S - Designates 80 ft/min

H - Designates 120 ft/min

D - Designates dual speed 80/20 ft/min |

|

1st

M - Max-E-Lift Style

T - Top Running

2nd M - Motorized

L - Speed of 40 ft/min

3 - Series Number

01 - Max. Capacity – 1 Ton

35 - Maximum Span – 35 feet |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

|

PRICING |

SERIES

3 - DOUBLE GIRDER END TRUCKS STANDARD VOLTAGE (208-230/460-3-60) |

|

|

TM-

TOP RUNNING MOTORIZED SINGLE SPEED |

|

| Product Code |

Cap. (Tons) |

Span |

Std. (FPM) |

Price/Pair |

| MTML-3-0135 |

1 |

to 35' |

40 |

|

| MTMS-3-0135 |

1 |

to 35' |

80 |

|

| MTMH-3-0135 |

1 |

to 35' |

120 |

|

| MTML-3-0160 |

1 |

to 60' |

40 |

|

| MTMS-3-0160 |

1 |

to 60' |

80 |

|

| MTMH-3-0160 |

1 |

to 60' |

120 |

|

| MTML-3-0335 |

3 |

to 35' |

40 |

|

| MTMS-3-0335 |

3 |

to 35' |

80 |

|

| MTMH-3-0335 |

3 |

to 35' |

120 |

|

| MTML-3-0360 |

3 |

to 60' |

40 |

|

| MTMS-3-0360 |

3 |

to 60' |

80 |

|

| MTMH-3-0360 |

3 |

to 60' |

120 |

|

| MTML-3-0535 |

5 |

to 35' |

40 |

|

| MTMS-3-0535 |

5 |

to 35' |

80 |

|

| MTMH-3-0535 |

5 |

to 35' |

120 |

|

| MTML-3-0560 |

5 |

to 60' |

40 |

|

| MTMS-3-0560 |

5 |

to 60' |

80 |

|

| MTMH-3-0560 |

5 |

to 60' |

120 |

|

| MTML-3-1035 |

10 |

to 35' |

40 |

|

| MTMS-3-1035 |

10 |

to 35' |

80 |

|

| MTMH-3-1035 |

10 |

to 35' |

120 |

|

| MTML-3-1060 |

10 |

to 60' |

40 |

|

| MTMS-3-1060 |

10 |

to 60' |

80 |

|

| MTMH-3-1060 |

10 |

to 60' |

120 |

|

|

|

|

|

|

TM-

TOP RUNNING MOTORIZED DUAL SPEED |

|

|

| Product Code |

Cap. (Tons) |

Span |

Std. (FPM) |

Price/Pair |

| MTMD-3-0135 |

1 |

to 35' |

80/20 |

|

| MTMD-3-0160 |

1 |

to 60' |

80/20 |

|

| MTMD-3-0335 |

3 |

to 35' |

80/20 |

|

| MTMD-3-0360 |

3 |

to 60' |

80/20 |

|

| MTMD-3-0535 |

5 |

to 35' |

80/20 |

|

| MTMD-3-0560 |

5 |

to 60' |

80/20 |

|

| MTMD-3-1035 |

10 |

to 35' |

80/20 |

|

| MTMD-3-1060 |

10 |

to 60' |

80/20 |

|

|

|

|

All motorized

end trucks

include one pair of end

trucks, two drive motors

with gear boxes,

adjustable electric brakes

and rubber bumpers. |

|

| Specify

runway rail size. |

|

| For

travel speeds other than standard, see accessories below. |

|

| For

plug and play connections - add $315.30 |

|

|

|

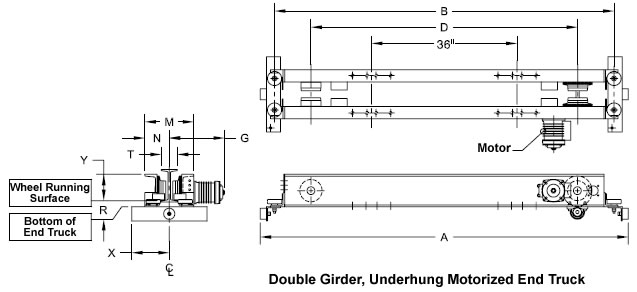

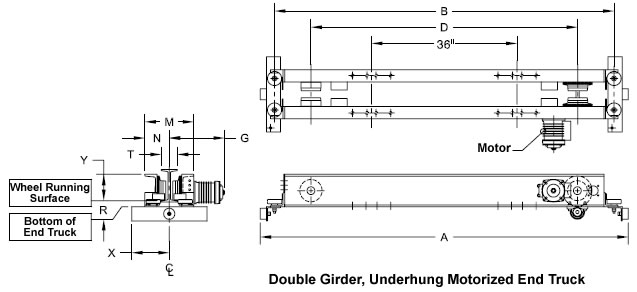

MUM—Double

Girder Max-E-Lift

|

Underhung

Motorized End Trucks |

|

Our

MUM end trucks offer the same benefits of the UM underhung motorized single

girder series, but in a compact,

double girder configuration. Unique for double girder cranes, these end

trucks offer the dimensional advantage of an

underhung crane combined with a top running trolley. Along with many important

features, end truck kits include: two

end trucks; two sealed, totally enclosed, nonventilated (TENV) motors with

adjustable electric brakes; two helical

gear reducers; rubber bumpers; and bridge beam fastener set. All trucks

are fully painted. Bridge fabrication prints

are also included. As a member of Crane Manufacturers Association of America

(CMAA), we build MUM trucks

to meet current industry and regulatory codes. |

|

|

MUM -

MAX-E-LIFT UNDERHUNG MOTORIZED END TRUCK - DIMENSIONS |

Cap.

(Tons) |

Max.

Span

(ft.) |

End Truck

Product Code |

Wheel

Dia.

(In) |

T

Flange

Range

Std. (in) |

A

Overall

Length

(in) |

B

Roller

Base

(in) |

D

Wheel

Base

(in) |

M

End

Truck

Frame

Width

(in) |

N

Runway

Ctr. Line

to Outer

Edge of

ET (in) |

R

Wheel

Running

Surf. To

Bottom of

Truck (in) |

X*

Width

Beyond

Span (in) |

Y

Wheel

Running

Surf. To

Upper Most

Part of ET (in) |

G

Motor

(in) |

| 2 |

35 |

MUML/S/H/D-3-0235 |

4.33 |

3 - 6 |

87 |

80 |

66 |

T+8.1 |

M/2 |

1.5 |

11.3 - T/2 |

6.5 |

T/2+

11.9 (L/S)

12.3 (H)

13.3 (D) |

| 50 |

MUML/S/H/D-3-0250 |

99 |

92 |

78 |

| 3 |

35 |

MUML/S/H/D3-0335 |

4.92 |

91 |

84 |

66 |

T+8.2 |

| 50 |

MUML/S/H/D-3-0350 |

103 |

96 |

78 |

| 5 |

35 |

MUML/S/H/D-3-0535 |

5.51 |

4 - 6 |

95 |

88 |

68 |

T+9.8 |

1.6 |

6.8 |

T/2+

13.7 (L/S/D)

14.2 (H) |

| 50 |

MUML/S/H/D-3-0550 |

107 |

100 |

80 |

|

| *These

formulas for Width Beyond Span do not apply for flanges greater than 6 inches.

For flanges greater than 6 inches, consult us. |

|

|

|

|

|

|

MUM -

MAX-E-LIFT UNDERHUNG MOTORIZED END TRUCK - SPECIFICATIONS |

End Truck

Product Code |

Speed

Codes L and S |

Speed

Code H |

Speed

Code D |

End Truck

Weight

(lbs/pr) |

One

Motor Per End Truck

3 Phase 60 Hz |

One

Motor Per End Truck

3 Phase 60 Hz |

One

Motor Per End Truck

3 Phase 60 Hz |

Output

(Hp) |

Rated Current

(amps ea.) |

Output

(Hp) |

Rated Current

(amps ea.) |

Output

(Hp) |

Rated Current

(amps ea.) |

| @230V |

@460V |

@230V |

@460V |

@230V |

@460V |

| MUML/S/H/D-3-0235 |

0.33 |

1.6 |

1.0 |

0.5 |

2.1 |

1.3 |

0.33/0.08 |

1.6/1.1 |

0.9/0.8 |

690 |

| MUML/S/H/D-3-0250 |

765 |

| MUML/S/H/D3-0335 |

736 |

| MUML/S/H/D-3-0350 |

811 |

| MUML/S/H/D-3-0535 |

0.5 |

2.1 |

1.3 |

1.0 |

3.3 |

2.0 |

0.5/0.13 |

2.0/1.5 |

1.2/0.9 |

888 |

MUML/S/H/D-3-0550 |

973 |

|

| Speed

Code |

|

Product

Code Derivation - example: MTML-3-0135 |

|

L

- Designates 40 ft/min

S - Designates 80 ft/min

H - Designates 120 ft/min

D - Designates dual speed 80/20 ft/min |

|

1st

M - Max-E-Lift Style

T - Top Running

2nd M - Motorized

L - Speed of 40 ft/min

3 - Series Number

01 - Max. Capacity – 1 Ton

35 - Maximum Span – 35 feet |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

|

PRICING |

SERIES

3 - DOUBLE GIRDER END TRUCKS STANDARD VOLTAGE (208-230/460-3-60) |

|

|

| UM

- UNDERHUNG MOTORIZED SINGLE SPEED |

|

| Product Code |

Cap. (Tons) |

Span |

Std. (FPM) |

Price/Pair |

| MUML-03-0235 |

2 |

to 35' |

40 |

|

| MUMS-3-0235 |

2 |

to 35' |

80 |

|

| MUMH-3-0235 |

2 |

to 35' |

120 |

|

| MUML-3-0250 |

2 |

to 50' |

40 |

|

| MUMS-3-0250 |

2 |

to 50' |

80 |

|

| MUMH-3-0250 |

2 |

to 50' |

120 |

|

| MUML-3-0335 |

3 |

to 35' |

40 |

|

| MUMS-3-0335 |

3 |

to 35' |

80 |

|

| MUMH-3-0335 |

3 |

to 35' |

120 |

|

| MUML-3-0350 |

3 |

to 50' |

40 |

|

| MUMS-3-0350 |

3 |

to 50' |

80 |

|

| MUMH-3-0350 |

3 |

to 50' |

120 |

|

| MUML-3-0535 |

5 |

to 35' |

40 |

|

| MUMS-3-0535 |

5 |

to 35' |

80 |

|

| MUMH-3-0535 |

5 |

to 35' |

120 |

|

| MUML-3-0550 |

5 |

to 50' |

40 |

|

| MUMS-3-0550 |

5 |

to 50' |

80 |

|

| MUMH-3-0550 |

5 |

to 50' |

120 |

|

|

|

|

|

UM

- UNDERHUNG MOTORIZED DUAL SPEED |

|

| Product Code |

Cap. (Tons) |

Span |

Std. (FPM) |

Price/Pair |

| MUMD-3-0235 |

2 |

to 35' |

80/20 |

|

| MUMD-3-0250 |

2 |

to 50' |

80/20 |

|

| MUMD-3-0335 |

3 |

to 35' |

80/20 |

|

| MUMD-3-0350 |

3 |

to 50' |

80/20 |

|

| MUMD-3-0535 |

5 |

to 35' |

80/20 |

|

| MUMD-3-0550 |

5 |

to 50' |

80/20 |

|

|

|

Specify runway flange width

and bridge beams.

For flange widths beyond 6 in. - add $654.90

For travel speeds other than standard, see

accessories below.

For plug and play connections - add $315.30 |

|

|

|

Patented

Track - Underhung End Trucks Only

For application approval: |

|

|

|

(1)

Give location of splice plates

(2) Give maximum web thickness including splice plates and hardware |

|

|

|

|

|

| On

approved application: |

|

|

|

(1)

Cutdown of 8 wheels required - add $287.00

(2) Hardened wheels is an option - add $3,290.00 |

|

|

|

|

|

|

All

motorized end trucks include one pair of end trucks, two drive motors with

gear boxes,

adjustable electric brakes and rubber bumpers. |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

CRANE

CONTROL PANELS |

|

|

|

|

|

| VARIABLE

FREQUENCY DRIVE |

|

|

|

|

|

| All

panels are certified to UL/CSA 508A and NEMA 4/12 |

Product

Code** |

Description |

Price |

Voltage |

Total

System Amps

| Max.

Total Crane Drive Amps* (1) |

P1V43 (1) |

460 |

24 |

4.0 |

|

P1V46 (1) |

460 |

48 |

9.0 |

|

12.5 |

|

P1V13

(1) |

208 / 230 |

24 |

5.9 |

|

P1V23

(1) |

|

P1V16 (1) |

208 / 230 |

48 |

7.5 |

|

P1V26

(1) |

16.5 |

|

P1V1X (1) |

208 / 230 |

80 |

24.0 |

|

PV2X

(1) |

|

|

|

|

|

|

|

| (1)

Total Crane Drive Amps Required |

|

|

24 =

2.4A

40 = 4.0A

59 = 5.9A

75 = 7.5A |

90 =

9.0A

X2=12.5A

X6 = 16.5A

Y4=24A |

|

|

|

|

|

|

|

*Actual

crane drive amps will be determined by system requirements.

** Plug and play connection (Availale up to 80A system)

- Panel with 5 male plugs (factory wired) - add $1,432.00

- Panel with 5 male plugs & mates (wiring by others) - add $2,005.00 |

|

|

|

|

|

| Standard

features included in all above Frequency Controls: |

|

|

|

|

|

Lock-out

compatible through-the-door manual disconnect switch with system

fusing, 110 volt control circuit

transformer with primary and secondary fusing, mainline contactor, Variable

Frequency Drive (VFD), brake relay,

branch circuit fusing for bridge, auto-reset thermal overload relay, and

bottom hinged door.

Mounting bracket included. |

|

|

|

|

|

These

panels can be used for dual and multiple speed applications, infinitely

variable speed applications and

programmed acceleration / deceleration control, using single speed end trucks.

VFD comes pre-loaded with many

easy-to-select programs to fit virtually any crane control application,

and includes fault-code trouble shooting. |

|

|

|

|

|

| THESE

ITEMS REPLACE STANDARD CRANE CONTROL PANELS. |

|

|

|

|

|

| If

more than two end truck motors to be controlled, consult us. |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

SINGLE

AND DUAL SPEEDS |

|

| Crane

Control Panels - Single Speed - All panels are certified to UL / CSA 508A

and NEMA 4/12 |

Product

Code**

| Description |

Price |

Voltage |

Total

System Amps

| Max.

Total Crane

Drive Amps* (1) |

P1S43 (1) |

460 |

24 |

4.0 |

|

P1S46 (1) |

460 |

48 |

8.0 |

|

P1S13 (1) |

208 / 230 |

24 |

4.0 |

|

P1S23

(1) |

8.0 |

|

P1S16 (1) |

208 / 230 |

48 |

8.0 |

|

P1S26

(1) |

16.0 |

|

P1S1X (1) |

208 / 230 |

80 |

8.0 |

|

P1S2X

(1) |

16.0 |

|

|

|

|

|

Crane

Control Panels - Dual Speed (for use with dual speed end truck drives)

All panels are certified to UL / CSA 508A and NEMA 4/12 |

Product

Code**

| Description |

Price |

Voltage |

Total

System Amps

| Max.

Total Crane Drive Amps* (1) |

P1D43 (1) |

460 |

24 |

4.0 |

|

P1D46 (1) |

460 |

48 |

8.0 |

|

P1D13 (1) |

208 / 230 |

24 |

8.0 |

|

|

P1D23

(1) |

P1D16 (1) |

208 / 230 |

48 |

16.0 |

|

|

P1D26

(1) |

P1D1X (1) |

208 / 230 |

80 |

16.0 |

|

|

P1D2X

(1) |

|

|

|

|

| (1) |

|

|

40

= 4.0A

80 = 8.0A

X6 = 16.0A |

|

|

|

|

|

|

*Actual

crane drive amps will be determined by system requirements.

** Plug and play connection (Availale up to 80A system)

- Panel with 5 male plugs (factory wired) - add $1,432.00

- Panel with 5 male plugs & mates (wiring by others) - add $2,005.00 |

|

|

|

Standard

features included in all above Crane Control Panels: *(Electronic acceleration

control not

included with 721E panel) |

|

|

|

Lockout

compatible through-the-door manual disconnect switch with system fusing,

110 volt control circuit

transformer with primary and secondary fusing, mainline contactor, mechanically

interlocked reversing contactor,

time and torque adjustable Electronic Acceleration Control (EAC),

branch circuit fusing for bridge, auto-reset

thermal overload relay, and bottom hinged door. Mounting bracket included. |

|

|

|

| If

more than two end truck motors to be controlled, consult us. |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

ELECTRICAL

AND MECHANICAL ASSEMBLY CHARGES |

Product

Code |

Description |

Price |

| WAC1 |

Single Girder Complete Crane System (Shipped unassembled) |

|

| WAC2 |

Single Girder Crane Package (No hoist or trolley) (Shipped unassembled) |

|

| WAC3 |

Trolley/Hoist modification (Special P/B, control voltage) |

|

| WAC4P* |

Partial Assembly Charge (End trucks, bracing and beam assembled)

(add to WAC1 or WAC2) |

|

| WAC4C* |

Complete Assembly Charge (All electrical / mechanical components fully

assembled)

(add to WAC1 or WAC2) |

|

| WAC5 |

Flat Cable Festooning |

|

|

|

NOTE: Labor charges for cutting wire, stripping and installing terminals,

installing wire and cables, and assembling

parts and/or components where applicable. |

|

*Preassembled

packages and systems will be shipped via dedicated carrier. Freight allowed

on L.T.L. weight of

500 pounds or more - additional dedicated carrier charges may apply. |

|

|

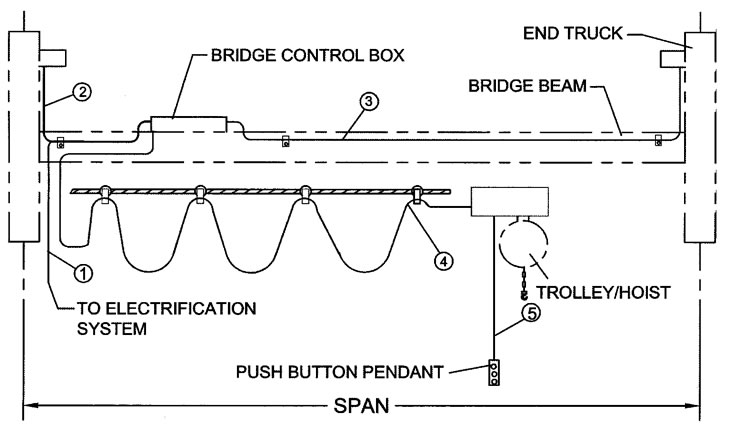

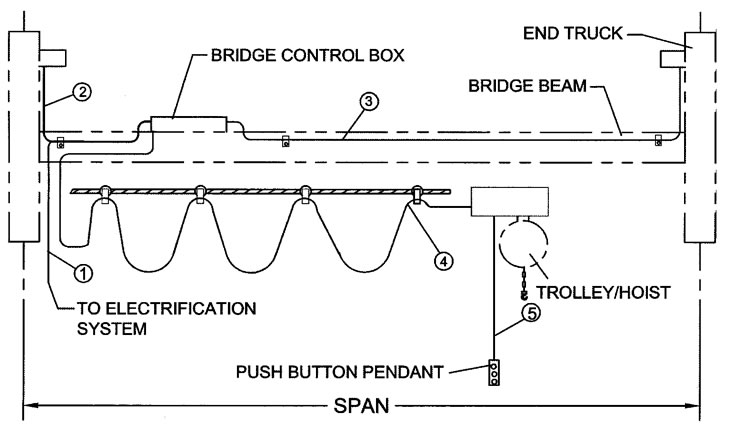

CRANE

WIRES FOR TOTAL CRANE SYSTEMS (see crane wiring diagram below) |

Product

Code |

Crane System

Wires |

Price* |

0Components

Included |

| CWA |

Crane System

To 30 AMP System

Up to 50' Span |

$593.28

+

$26.38/ft.

of span |

Wires 1 through 5,

Appropriate cable hangers

and guide wire kit |

| CWB |

Crane System

To 45 AMP System

Up to 50' Span |

$609.04

+

$29.64/ft.

of span |

Wires

1 through 5,

Appropriate cable hangers

and guide wire kit |

| CWE |

Crane System

To 30 AMP System

Up to 60' Span |

$819.70

+

$21.67/ft.

of span |

Wires

1, 2 , 3 and 5

Use with DWRPA or ECE3 |

| CWF |

Crane System

To 45 AMP System

Up to 60' Span |

$899.95

+

$21.67/ft.

of span |

Wires

1, 2 , 3 and 5

Use with DWRPA or ECE3 |

| CWG |

Crane System

To 45 AMP System

Up to 60' Span |

$1,028.92

+

$29.61/ft.

of span |

Wires

1, 2 , 3 and 5

Use with DWRPA or ECE3 |

|

| NOTE: Standard pendant drop is 6 ft. Extra per ft. is $20.22 |

|

| *For

plug and play connections - add $534.52 |

|

|

|

|

| Festooned

Flat Cable Electrification |

|

Flat

cable hoist power cord -

Product Code DWRPA

Includes: 12/4 and 16/8 flat cable, C-track, suspension bars, and cable

hangers. |

|

| Price: $342.50 /set plus $32.17per

ft. of travel + WAC5 charge of $706.00 |

|

WAC5

applies only once if both DWRPA and DWRPB are ordered.

For plug and play connections - add $644.87 when system includes RHN (RHN includes plug at panel and hoist)

add $229.29 when system includes ER2 (ER2 includes plug at panel, but is direct wired

at hoist) |

|

|

| All

permanently located wiring is routed through electrical metallic (EMT) and

liquid tight conduit. |

|

Double Girder Max-E-Lift,

Harrington Motorized End Trucks, Top Running Motorized End Trucks, Underhung

Motorized End Trucks, Double Girder End Trucks, Max-E-Lift Motorized End

Trucks, and Single / Dual Speed

Motorized End Trucks from your source for material handling equipment. |

Back

to Product Category |

|

|