|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

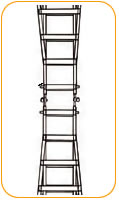

LITTLE

GIANT 375 LADDER SYSTEMS

SUPER DUTY TYPE 1AA

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For heavy-duty jobs, nothing

beats the Super Duty

Type 1AA Little Giant Ladder.

When you need industrial-strength,

only one ladder will

do—the Little Giant Type 1AA. It’s government rated

to a whopping 375 pounds, so you know it can stand up

to even the most demanding applications.

And because it’s a Little

Giant, the Type 1AA gives you

the advantages of traditional A-frame ladders, extension

ladders, stepladders and even scaffolding—all in one

convenient package. |

|

Safety

The Little Giant is designed to be the safest ladder on

the planet. Since it’s adjustable, the Little Giant can

be used safely on stairs, ramps, curbs, docks or other

uneven surfaces. |

|

|

|

|

|

|

Strength

The Little Giant is made of heavy-wall, 6005-T5

aluminum—the very same material used in aerospace

construction. So it’s ultra-strong while remaining light

and portable.

In fact, The Little Giant Type 1AA is government-rated

to hold up to 375 pounds, but has survived brutal stress

testing of up to 1200 pounds with absolutely no

structural failure. |

|

|

|

|

|

|

Little

Giant Type 1AA Features:

* Heavy-wall aircraft-grade

aluminum construction

* Rated to hold up to 375 lbs.

* Combines 24 different ladders into on convenient system

* Lightweight and portable

* Complies with all applicable OSHA ANSI A14.2

standards

* Includes a full Lifetime Warranty |

|

|

|

|

|

|

Versatility

No other ladder gives you the versatility of a Little

Giant. Independent tests prove the Little Giant will

replace 60-70% of all portable ladders currently being

manufactured.

When you buy a Little Giant, you’re not just getting one

ladder. You’re getting 24 different ladders combined to

make the world’s most versatile ladder system. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

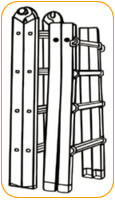

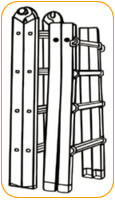

Little Giant Ladder

Configurations: |

|

|

|

|

|

|

|

|

|

|

|

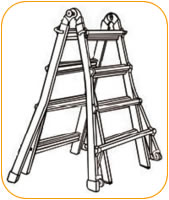

A-Frame Ladder

With a simple click of the patented hinge, the Little Giant can be used

as a

traditional A-Frame ladder. |

|

|

|

|

|

|

|

|

|

|

A-Frame

Ladder |

|

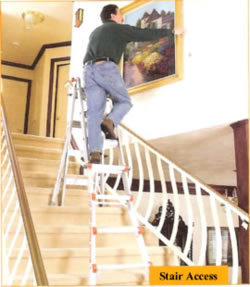

Staircase

Ladder

Because it's adjustable in one-foot increments, the Little Giant allows

one side

of the ladder to be extended allowing safe use on uneven surfaces like

staircases,

curbs or docks. |

|

|

|

|

|

|

|

|

|

|

|

Staircase

Ladder |

|

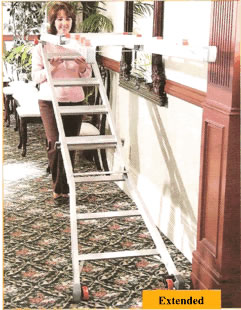

90°

Ladder

Traditional ladders make working close to walls nearly impossible. With

the Little

Giant, one adjustment allows you to safely work against any vertical surface. |

|

|

|

|

|

90°

Ladder |

|

Extension

Ladder

For large projects the Little Giant easily converts to a stable extension

ladder allowing you to reach rooftops, tree limbs and more with ease. |

|

|

|

|

|

|

|

|

|

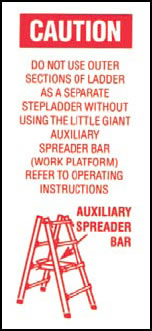

Scaffolding

Since the Little Giant pulls apart to form two scaffold trestles, you just

add the Little Giant work plank (sold separately) to form a convenient scaffolding

system. |

|

Extension

Ladder |

|

|

|

|

|

|

|

Scaffolding |

|

|

|

|

|

|

|

|

|

Specifications

- 375 lbs. Rated - Lifetime Warranty |

| Part # |

Model No. |

Stepladder

Height |

Extension

Height |

Scaffolding

Height |

Storage

Height |

Weight

Capacity |

| 10401 |

M13 |

3'-5' |

7'-11' |

3' |

3' 7" |

375 lbs |

| 10402 |

M17 |

4'-7' |

9'-15' |

4' |

4' 7" |

375 lbs |

| 10403 |

M22 |

5'-9' |

11'-19' |

5' |

5' 7" |

375 lbs |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Part No. of the item you wish to

purchase. |

|

|

PRICES

FOR 375 LADDERS |

| Part No. |

Description |

Weight |

Prices |

| 10401 |

13' |

36 lbs |

$548.33 |

| 10402 |

17' |

45 lbs |

$600.00 |

| 10403 |

22' |

54 lbs |

$676.67 |

|

|

|

|

|

|

|

|

|

|

|

|

Accessories |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WingSpan

Ladder

Stand Off

Model No. - 10111 |

|

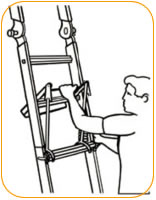

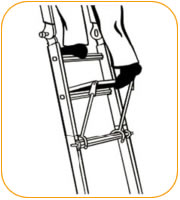

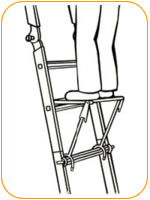

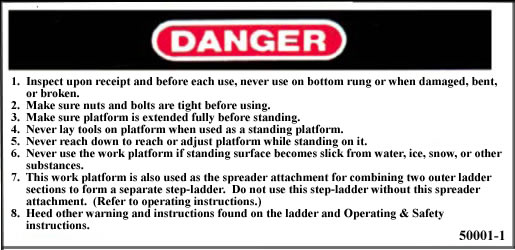

Work Platform

Model No. - 10104

300 lbs Rated |

|

Tip &

Glide Wheel Kit

Model No. - 10940 |

|

|

|

|

|

|

|

Ladder

Plank (250 lbs Rated)

Model No. - 11069 - 9' (6' to 9')

Model No. - 11813 - 13' (8' to 13')

Model No. - 11915 - 15' (9' to 15') |

|

|

Ladder Rack

Model No. - 15097

75 lbs Rated |

|

|

|

|

|

|

|

Project

Tray

Model No. - 15012 |

|

Cargo

Hold

Model No. - 15040-001 |

|

Fuel

Tank

Model No. - 15050-001 |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Part No. of the item you wish to

purchase. |

|

|

PRICES

FOR ACCESSORIES |

Part

No. |

Description |

Weight

(lbs) |

Prices |

|

Work

Platform |

8 |

$53.33 |

|

WingSpan

Ladder StandOff |

10 |

$61.67 |

|

Tip

& Glide Wheel Kit |

2 |

$33.33 |

|

Ladder

Rack |

8 |

$33.33 |

|

6'

- 9' Adjustable Plank |

35 |

$308.33 |

|

8'

- 13' Adjustable Plank |

48 |

$376.67 |

|

9'

- 15' Adjustable Plank |

59 |

$440.00 |

|

Project

Tray |

- |

$46.67 |

|

Cargo

Hold |

- |

$25.00 |

|

Fuel

Tank |

- |

$40.00 |

|

|

|

Operating

Instructions for Little Giant Ladder System® |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

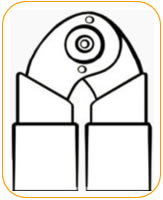

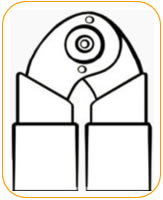

A. The Hinge - located

at the top of the ladder when it is in storage position, permits you to

alter the shape of the ladder.

The hinge locks in the following positions (See Figures A-1, A-2, and

A-3). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure

A-1 |

|

|

|

|

|

Figure

A-2 |

|

|

|

|

Figure

A-3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

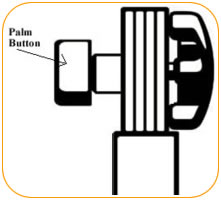

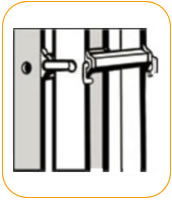

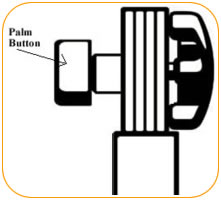

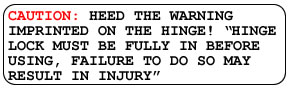

1. Unlock the hinge by pushing

straight in on the Palm Button until it stays in the open (unlocked) position

on both

hinges (See Figures A-4 and A-5). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure

A-4

LOCKED |

|

|

Figure

A-5

UNLOCKED |

|

|

|

|

Hinge |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

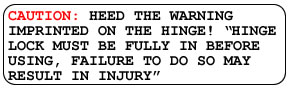

a.

NOTE - If there is pressure on hinge lock pins it will be difficult to unlock

the hinge. To relieve pressure,

simply adjust one half of the ladder back and forth until hinge lock pins

move without force. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

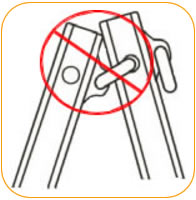

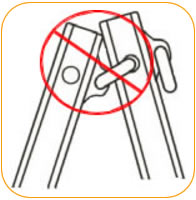

b.

NOTE - DO NOT FORCE HINGE LOCK in or out with any tools as it will cause

permanent damage to

the hinge mechanism. It should never require more than light pressure to

unlock the hinge if the holes are

properly aligned. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.

You may now open the ladder to the A-frame position by pulling the two ladder

halves apart until both hinge lock

pins snap into the A-frame locked position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.

Now place the ladder into the extension position by again pushing straight

in on the palm buttons of both hinges

(See Figures A-4 and A-5). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rotate

either side of the ladder until the hinge locks snap into their locked position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To

restore the ladder to the storage position, reverse the above procedure.

The hinge lock will lock automatically at

the A-frame configuration to prevent damage to the ladder or injury to the

user. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Use

caution and do not let the full weight of the ladder fall on the hinge lock

as the ladder folds from extension to

A-frame configuration. Disengage the hinge locks in the A-frame position

and return the ladder to its storage position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

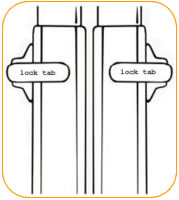

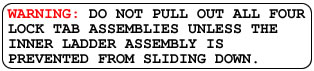

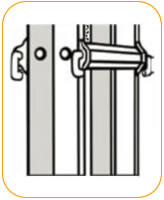

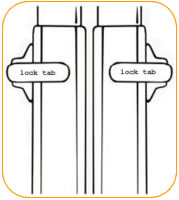

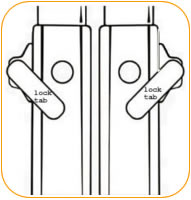

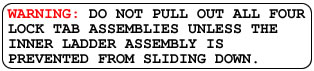

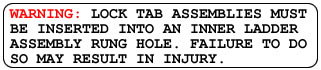

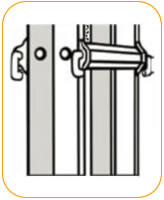

B.

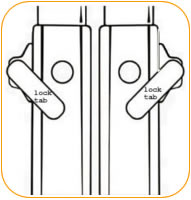

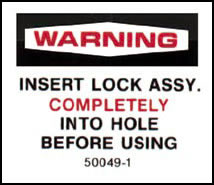

The Lock Tab Assemblies- The second mechanical component of the ladder

system is the LOCK TAB

ASSEMBLY. There are four of these on each ladder. These permit you to change

the height of the ladder (See

figure B-1 and C-1). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure

B-1 |

|

Figure

C-1 |

|

Figure

C-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| C.

Adjusting the height of the ladder for use in the A-frame position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

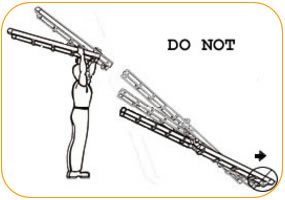

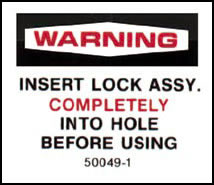

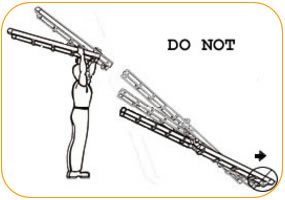

1.

Unlock both hinge locks (See figures A-4 & A-5).

2. With the ladder in the storage position and while holding the inner ladder

assembly firmly in place, pull the four

Lock Tab Assemblies out of the rung holes of the inner ladder and rest them

on the side of the outer ladder rail

(See figures C-1).

3. Raise the inner ladder up to the desired height.

4. At the desired height align the outer holes with the nearest rung hole

of the inner ladder assembly. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

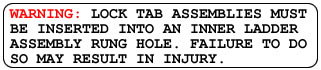

5.

Holding the inner and outer ladder at the aligned height with one hand,

reinsert the opposite Lock Tab Assemblies

into the rung holes with the other hand.

6. Alternate hands and perform the same operation with the other Lock Tab

Assemblies (See figure C-2). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.

Open the ladder to the A-frame configuration by pulling the ladder halves

apart until the hinges lock into place

(See figure A-2 and A-4).

8. To return the ladder to the storage position, reverse the procedures

and position as seen in Figure A-1. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

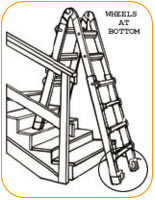

| D.

Adjusting the height of the ladder in its extension ladder position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. From its stored position,

unlock hinge (as indicated in figures A-4 & A-5)

and rotate to extension position until both hinges lock into place.

NOTE: Hinge will first lock in A-frame position, repeat unlocking

hinge to

rotate its extension position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure

D-1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

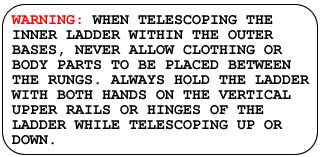

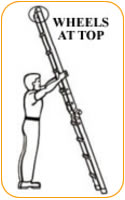

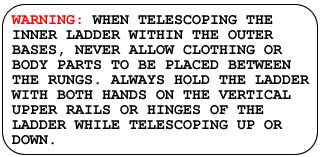

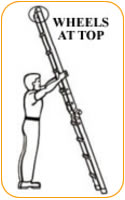

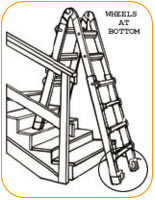

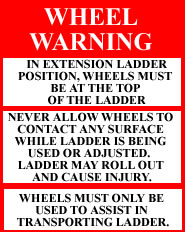

2.

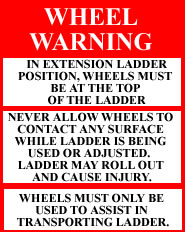

If equipped with wheels, wheels must be at the top of the ladder while

in the extension position. Unlock Lock Tab Assemblies on upper half of

the ladder. Grasp the outer ladder, walk backward, allowing the ladder

to telescope to the desired height. If more height is desired, extend the

lower half of the ladder (see figure D-1). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure

D-1A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

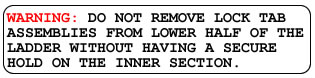

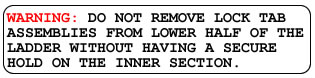

3.

To store the ladder from its extension position, reverse

the above sequence starting with the lower half of the

ladder. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| E.

Staircase Position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

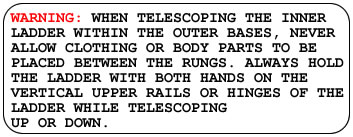

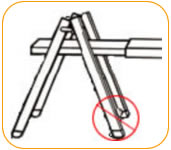

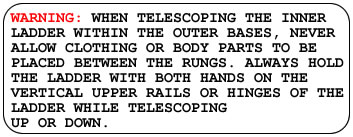

1.

Adjust ladder to desired height (review section

concerning adjusting the height of the ladder for use in the

A-frame position.) If equipped with wheels, the wheels

should be placed on the bottom of the long side, not against

the stairs. |

|

|

|

|

|

|

|

|

Figure

E-1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.

Then adjust the side desired for proper alignment to fit the

staircase (see figure E-1). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

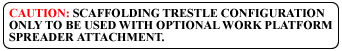

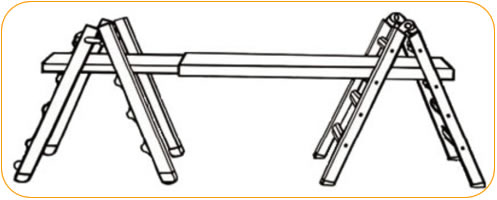

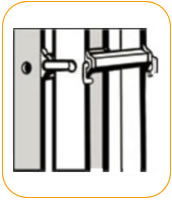

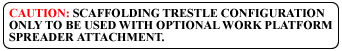

| F.

Scaffolding Trestle Operating Instructions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

Pull the inner ladder assembly completely out of the outer

ladder bases (see figure F-1). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.

Open the inner ladder assembly to the A-frame position until

both hinges lock (See figures A-4 and A-5). This is the first of

two trestles needed for the scaffolding function (see figure F-2). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.

Grasp both outer ladder bases (see figure F-3). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

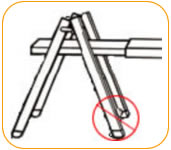

4.

If equipped with wheels, turn ladder without wheels 180º

and insert lock assemblies of that base into the adjacent holes

of the opposite outer base (see figure F-4). Wheels should be

facing out (see figure F-5). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure

F-1 |

|

|

|

|

|

Figure

F-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

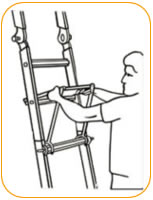

5.

Grasp the outer ladder base with the unused lock assemblies

and lower 1/2 inch, then spread the opposite outer ladder base

to form a second A-frame trestle (see figure F-5 and F-5

Close). |

|

|

|

|

|

|

|

|

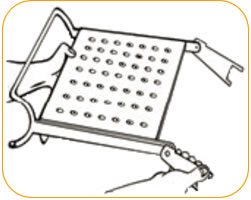

6.

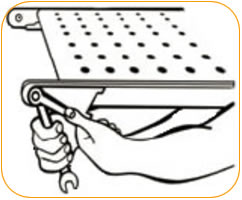

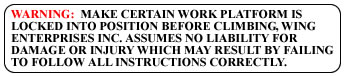

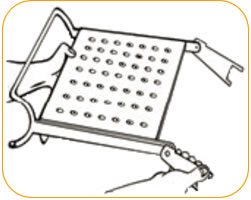

Rotate forked ears on work platform to position indicated

in figure F-6. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.

Insert work platform between outer ladder bases on the

third rung down of each base. The wire-formed end of the

work platform should surround the outer rung turned to the

inside of the outer ladder A-frame trestle (see figure F-7). |

|

|

|

|

|

|

|

|

Figure

F-3 |

|

|

|

Figure

F-4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure

F-5 Close |

Doing this

step

incorrectly may cause

damage to ladder. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure

F-6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wheels should

not be

on inside of trestle |

|

|

|

|

|

|

|

|

|

|

|

Figure

F-7 |

|

|

|

|

Figure

F-5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Little Giant 375 Ladder Systems

Type 1AA, Aluminum Step Ladder, Extension Ladder, used Safely on Stairs,

Ramps, Curbs, Docks or

other uneven surfaces, Aluminum, OSHA, 24 Different Ladders Combined,

A-Frame Ladder, Stair Access, Staircase Ladder, 90 Degree

Ladder, Extension Ladder, Scaffolding, and Telescoping Plank from your

source for material handling equipment. |

Back

to Product Category |

|

|