|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back

to Product Category

|

|

|

|

|

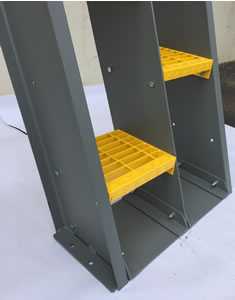

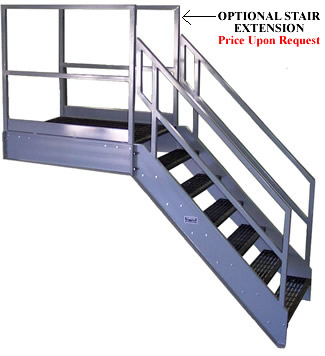

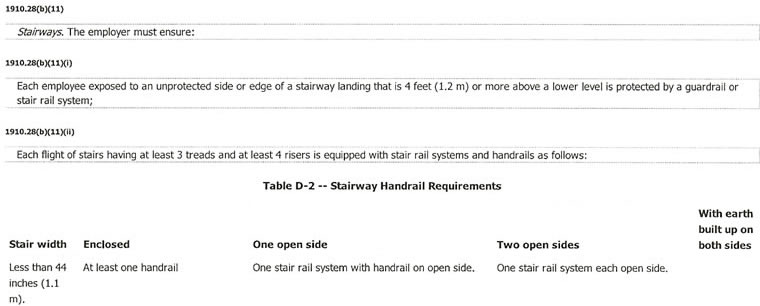

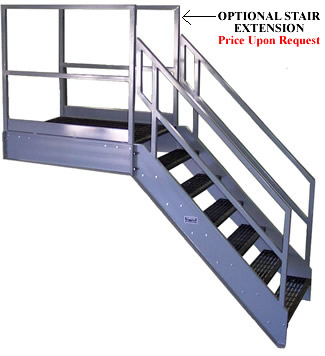

Order

all galvanized

frame and tread finish

for maximum durability

and corrosion resistance. |

|

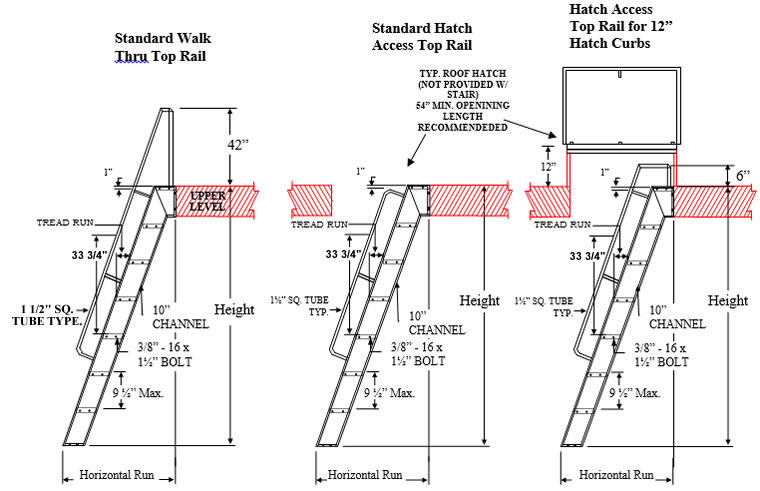

OSHA stair

shown with optional

horizontal extension. |

|

|

|

|

|

|

|

|

|

|

CUSTOM

SIZES - SAME DAY QUOTES |

|

Custom

sizes and configurations are readily available. We provide same day price

quotes if you require a special

stair angle, specific tread rise/run, or a maximum horizontal stair run

to satisfy available floor space constraints. |

|

NEW!

Optional Finishes! |

Our

standard finish is a quick dry polyester powder coat Gray (RAL

7005).

Also available in Black (RAL 9005), Blue (RAL

5010), White (RAL 9016) and

Safety Yellow (RAL 1023). In addition we are pleased to offer our products

with a

hot-dipped

galvanized finish or in a Two Part System which is our powder coat over a

hot-dipped galvanized undercoat. |

|

|

|

Color

Disclaimer: Please note

that the appearance of the color blocks shown above may vary depending on

the device used

to view this web page. |

|

PRICING

FOR ALTERNATING TREAD STAIRS WITH

STANDARD POWDER COATED FRAME |

|

|

|

|

|

|

|

|

|

This

is a steep incline stair not acceptable for public

access, office use, or residential applications. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steel

Stair Treads |

|

Other

tread types and sizes available upon request |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

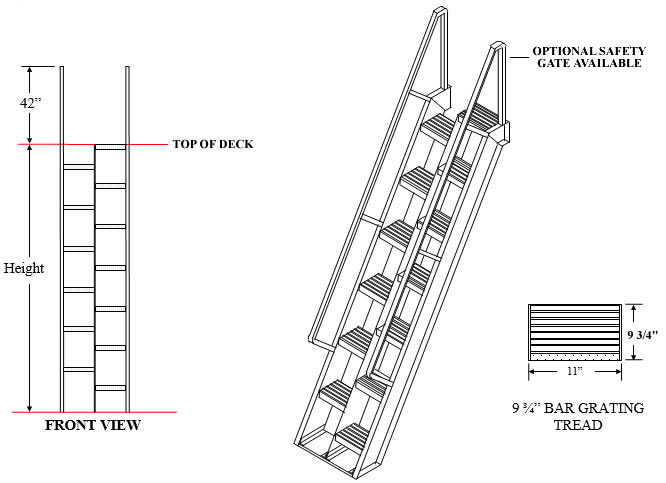

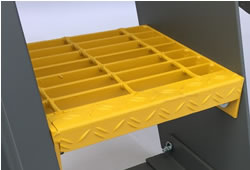

Bar

grating stair treads are safe, self-

cleaning, skid-resistant and economical. |

|

|

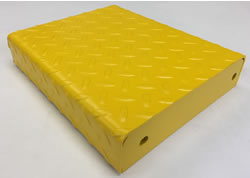

9

1/2" Dia. Plate Tread |

|

|

|

|

|

|

Powder

Coated yellow for high visibility |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

PRICES

FOR ALTERNATING TREAD STEEL STAIRS

WITH BAR GRATING TREADS |

Type

Model No. |

(A)

Height Range |

(B)

Horizontal

Run @ 68 deg. |

Tread

Width |

Nominal

Overall

Width |

(A)

Price

w/Powder

Coated Frame

Bar Grating

Treads |

(B)

Price with

Galvanized

Finish |

Price

with

Galvanized &

Powder

Coated |

Lower

Ht. (in) |

Upper

Ht. (in) |

ALTS2438 |

36" |

41" |

24

5/16 - 26 5/16 |

11" |

27" |

|

|

|

ALTS2444 |

42" |

47" |

26

3/4 - 28 3/4 |

11" |

27" |

|

|

|

ALTS2450 |

48" |

53" |

29

3/16 - 31 3/16 |

11" |

27" |

|

|

|

ALTS2456 |

54" |

59" |

31

9/16 - 33 5/8 |

11" |

27" |

|

|

|

ALTS2462 |

60" |

65" |

34

- 36 1/16 |

11" |

27" |

|

|

|

ALTS2468 |

66" |

71" |

36

7/16 - 38 7/16 |

11" |

27" |

|

|

|

ALTS2474 |

72" |

77" |

38

7/8 - 40 7/8 |

11" |

27" |

|

|

|

ALTS2480 |

78" |

83" |

41

5/16 - 43 5/16 |

11" |

27" |

|

|

|

ALTS2486 |

84" |

89" |

43

11/16 - 45 3/4 |

11" |

27" |

|

|

|

ALTS2490 |

90" |

95" |

46

1/8 - 48 3/16 |

11" |

27" |

|

|

|

ALTS2498 |

96" |

101" |

48

9/16 - 50 9/16 |

11" |

27" |

|

|

|

ALTS24104 |

102" |

107" |

51

- 53 |

11" |

27" |

|

|

|

ALTS24110 |

108" |

113" |

53

7/16 - 55 7/16 |

11" |

27" |

|

|

|

ALTS24116 |

114" |

119" |

55

13/16 - 57 7/8 |

11" |

27" |

|

|

|

ALTS24122 |

120" |

125" |

58

1/4 - 60 1/4 |

11" |

27" |

|

|

|

ALTS24128 |

126" |

131" |

60

11/16 - 62 11/16 |

11" |

27" |

|

|

|

ALTS24134 |

132" |

137" |

63

1/8 - 65 1/8 |

11" |

27" |

|

|

|

ALTS24140 |

138" |

143" |

65

1/2 - 67 9/16 |

11" |

27" |

|

|

|

ALTS24146 |

144" |

149" |

67

15/16 - 70 |

11" |

27" |

|

|

|

ALTS24152 |

150" |

155" |

70

3/8 - 72 3/8 |

11" |

27" |

|

|

|

ALTS24158 |

156" |

161" |

72

13/16 - 74 13/16 |

11" |

27" |

|

|

|

ALTS24164 |

162" |

167" |

75

1/4 - 77 1/4 |

11" |

27" |

|

|

|

ALTS24170 |

168" |

173" |

77

5/8 - 79 11/16 |

11" |

27" |

|

|

|

ALTS24178 |

174" |

179" |

80

1/16 - 82 1/8 |

11" |

27" |

|

|

|

ALTS24184 |

180" |

185" |

82

1/2 - 84 1/2 |

11" |

27" |

|

|

|

ALTS24190 |

186" |

191" |

84

15/16 - 86 15/16 |

11" |

27" |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Model No. of the item you wish to

purchase. |

|

|

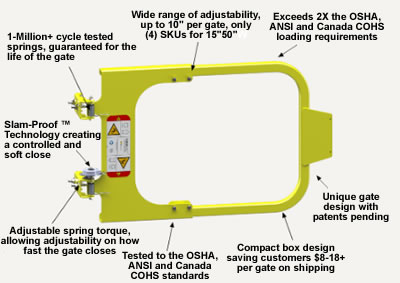

PRICES

FOR SAFETY GATE |

Powder

Coat

Safety Yellow |

Hot-Dip

Galvanized |

Railing

Opening

Width |

Flat

Surface

Opening Width

| Ship

Wgt

(lbs.)

| Price

Ea. |

Powder

Coat

Safety Yellow |

Hot-Dip

Galv. |

Model

No. |

Model

No. |

Min. |

Max. |

Min. |

Max. |

|

|

20" |

30" |

22

5/16" |

32

9/16" |

24 |

$408 |

$528 |

|

|

FACTORY

LOAD TEST |

|

|

|

|

|

|

|

|

|

|

In

addition to theoretical

design analysis

FS Industries has

performed actual load

tests with a 25%

overload to insure

design conformance to

OSHA standard 1910.25

which is printed below

test photos. |

|

|

|

|

|

|

|

1250 lbs.

concentrated load applied

to the center span of stair tread on a

3" long x 1 1/2" flat bar bearing surface. |

|

Underside

view of 1250 lbs.

Concentrated load suspended

from center of stair tread. |

|

|

|

|

|

|

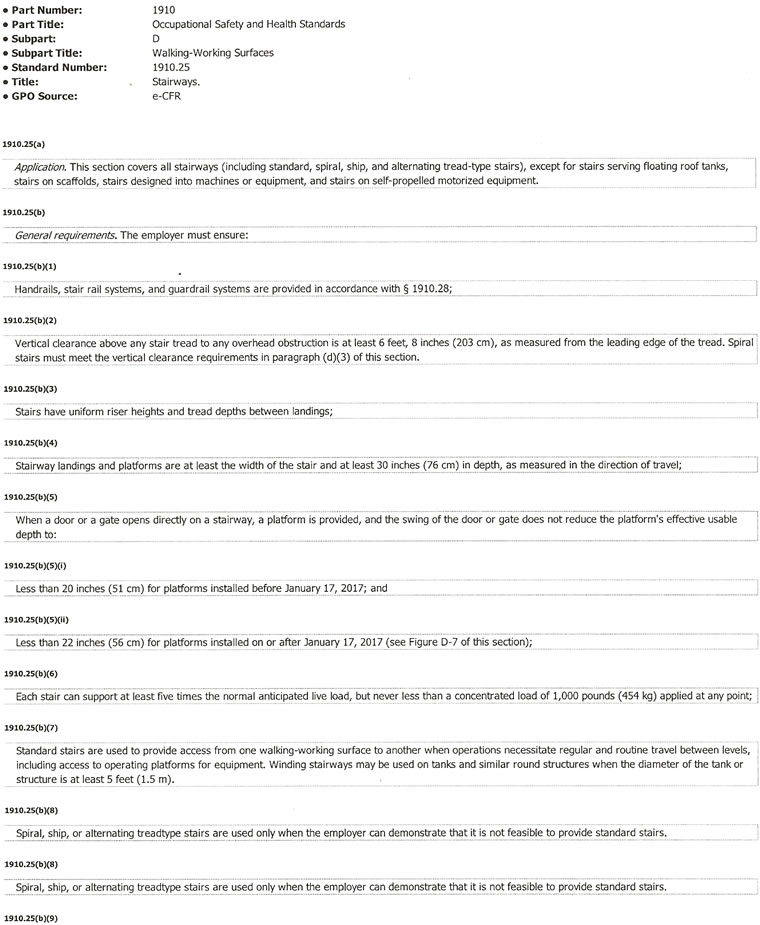

INTERNATIONAL

BUILDING CODE STANDARDS |

|

|

|

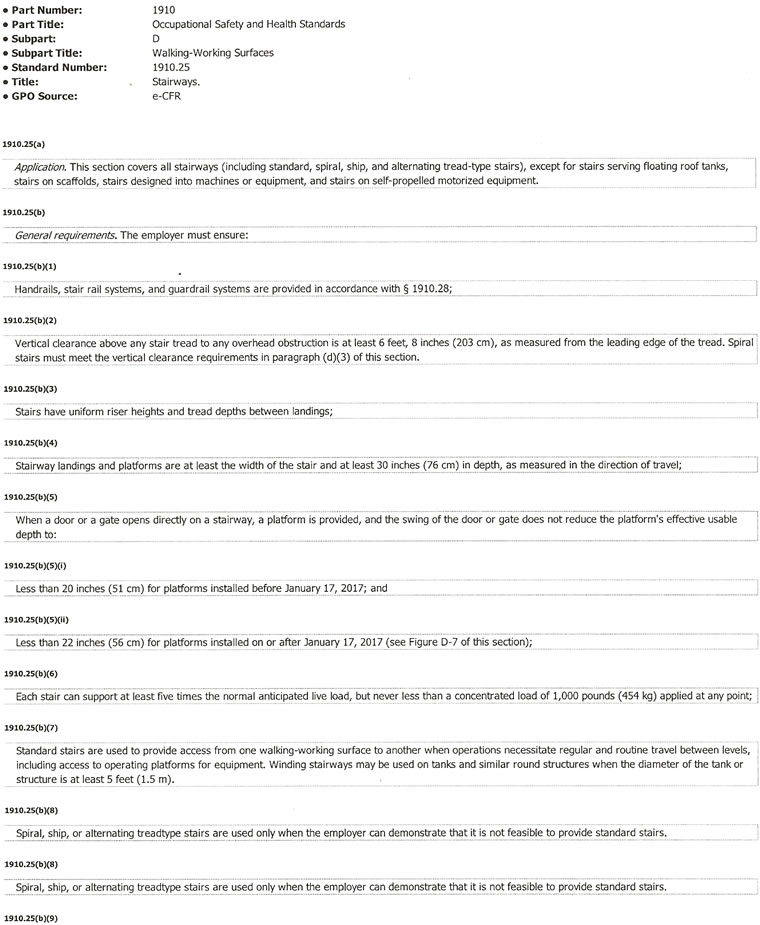

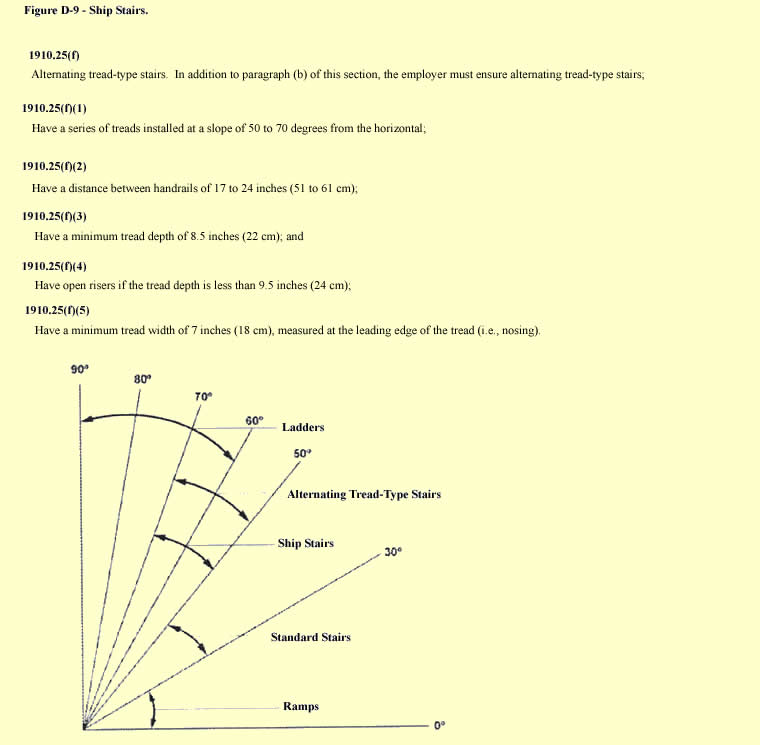

| 1011.14

Alternating tread devices. |

1011.14.2

Treads of alternating tread devices. |

Alternating

tread devices are limited to an element of a

means of egress in buildings of Groups F, H and S

from a mezzanine not more than 250 square feet (23 m²)

in area and that serves not more than five occupants; in

buildings of Group I-3 from a guard tower, observation

station or control room not more than 250 square feet

(23 m²) in area and for access to unoccupied roofs.

Alternating tread devices used as a means of egress

shall not have a rise greater than 20 feet (6096 mm)

between floor levels or landings. |

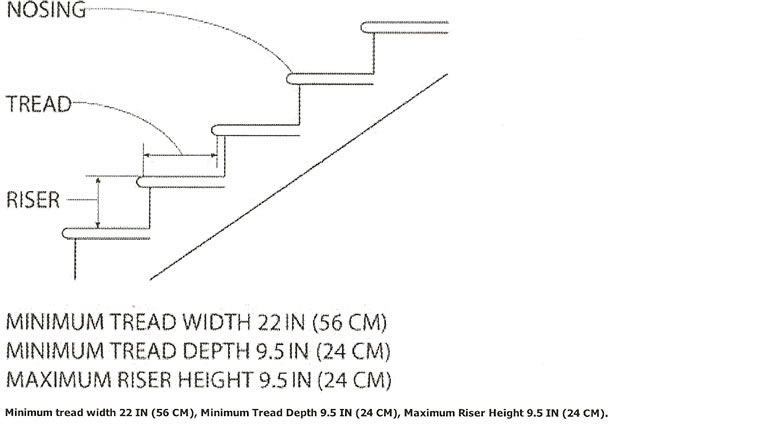

Alternating

tread devices shall have a minimum tread

depth of 5 inches (127 mm), a minimum projected

tread depth of 8 1/2 inches (216 mm), a minimum

tread width of 7 inches (178 mm) and a maximum

riser height of 9 1/2 inches (241 mm). The tread

depth shall be measured horizontally between the

vertical planes of the foremost projections of adjacent

treads. The riser height shall be measured vertically

between the leading edges of adjacent treads. The riser

height and tread depth provided shall result in an angle

of ascent from the horizontal of between 50 and 70

degrees (0.87 and 1.22 rad). The initial tread of the

device shall begin at the same elevation as the platform,

landing or floor surface. |

|

| 1011.14.1

Handrails of alternating tread devices. |

Handrails

shall be provided on both sides of alternating

tread devices and shall comply with Section 1014. |

|

|

|

|

|

|

Exception: Alternating tread devices used a an

element of a means of egress in buildings from a

mezzanine area not more than 250 square feet (23m²)

in area that serves not more than five occupants shall

have a minimum tread depth of 3 inches (76 mm) with

a minimum projected tread depth of 10 1/2 inches

(267 mm). The rise to the next alternating tread surface

shall not exceed 8 inches (203 mm). |

|

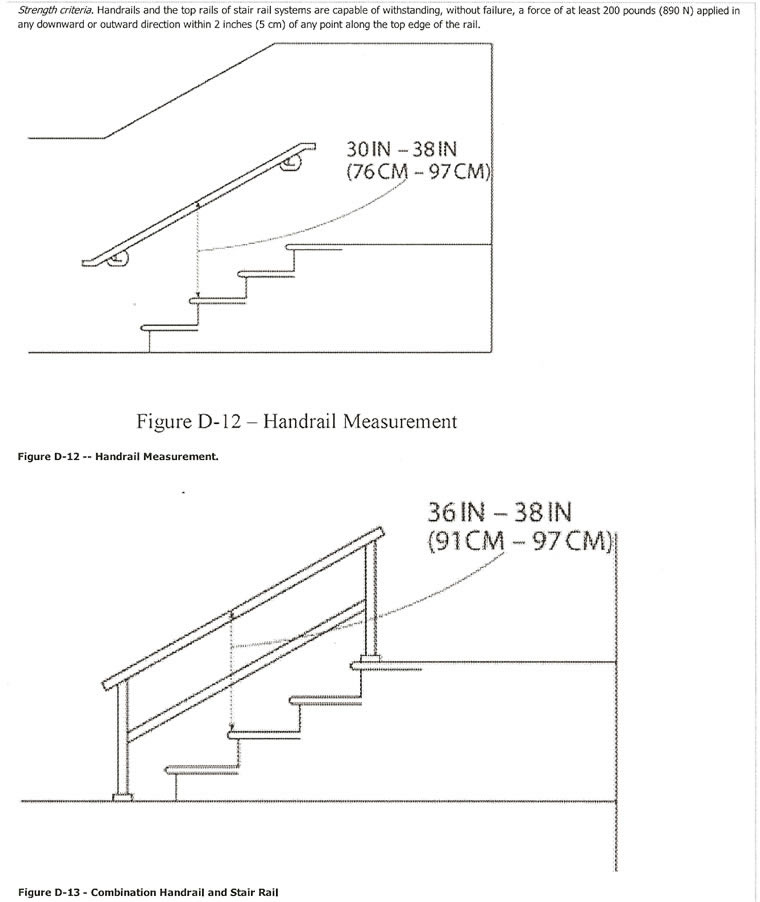

OSHA

STANDARD 1910.25 STAIRWAYS |

|

|

|

|

|

|

|

Walking-Working

Surfaces and Personal Fall Protection Systems Final Rule

Frequently Asked Questions |

The

intent of OSHA’s Walking-Working Surfaces standard, 29 CFR Part 1910,

Subpart D & I, is to increase the

protection of general industry employees and employers from hazards associated

with walking-working surfaces. The

rule making will significantly reduce the number of worker deaths and injuries

that occur each year resulting from

workplace slip, trip, and fall hazards. The final rule was published on

November 18, 2016, and became effective on

January 17, 2017. Some requirements in the final rule have compliance dates

after the effective date and will be

discussed in further detail below. This final rule and the associated preamble,

providing more detailed explanation of

the rule, is available on the Federal Register website at 81 FR 82494, Walking-Working

Surfaces; Personal Protective

Equipment; Final Rule, November 18, 2016.

OSHA requirements are set by statute, standards, and regulations. The Agency’s

interpretations explain these require-

ments and how they apply to particular circumstances, but they do not create

additional employer obligations. Note

that our enforcement guidance may be affected by legislative or rule making

changes to OSHA requirements. Also,

from time to time we update our guidance in response to new information.

To keep apprised of such developments,

you can consult OSHA’s website at http://www.osha.gov.

This webpage provides guidance, in a question and answer format, regarding

OSHA’s Final Rule, Walking-Working

Surfaces and Personal Protective Equipment, 29 CFR Part 1910, Subpart D

and I. These Frequently Asked Questions

(FAQs) are divided into five sections: general questions, rope descent system

(RDS) questions, outdoor advertising

questions, residential roof questions, and agricultural operation questions. |

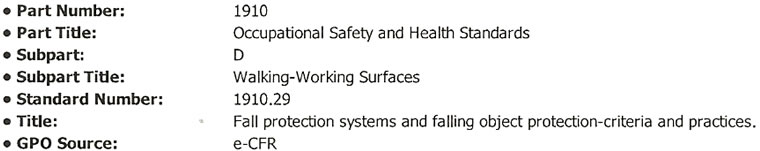

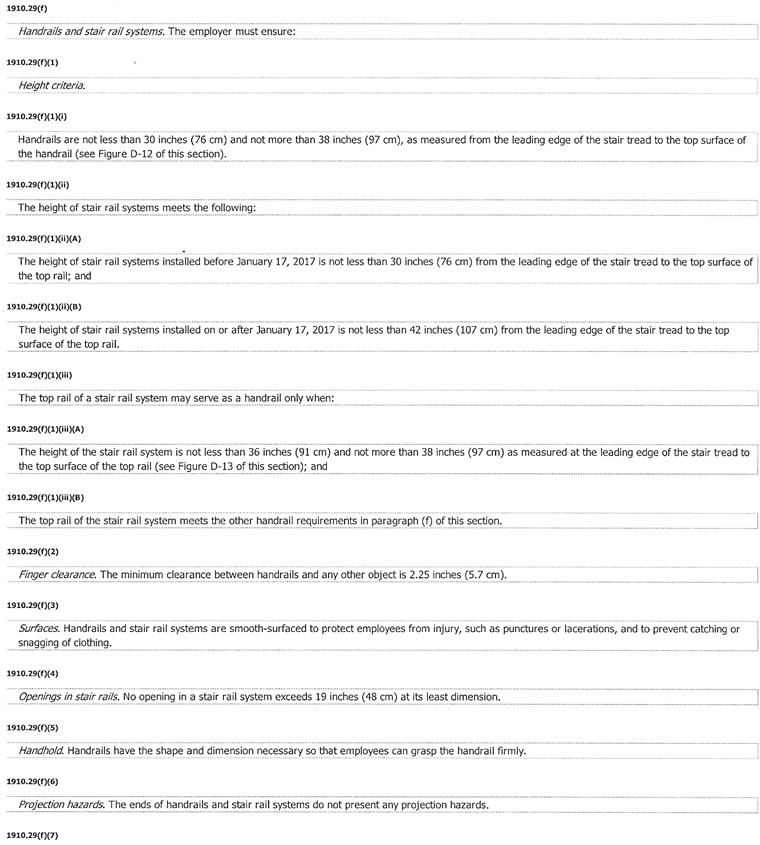

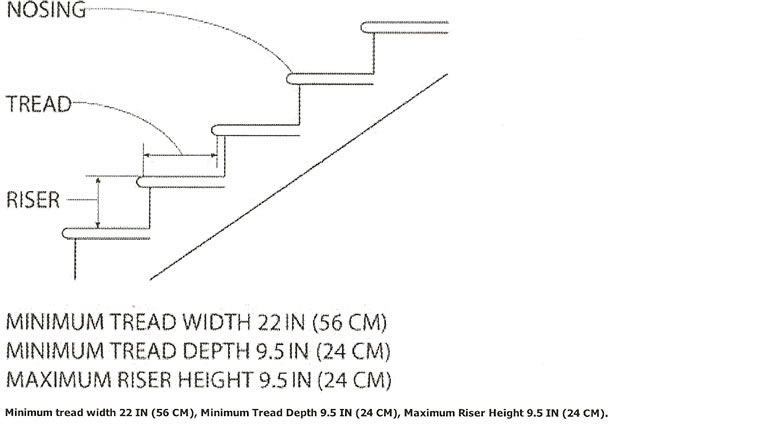

| Standard

Stairs |

Does

the exception to the 9.5-inch riser height and 9.5-inch tread depth requirements

for stairs installed before

January 17, 2017 (§19210.25(c)(5)), also apply to stairs designed and

fabricated, but not yet installed, by that date? |

Stairs

with design drawings issued for construction or that were in fabrication

before January 17, 2017, but not

installed, will be in compliance if they met the previous requirements for

standard stairs. |

|

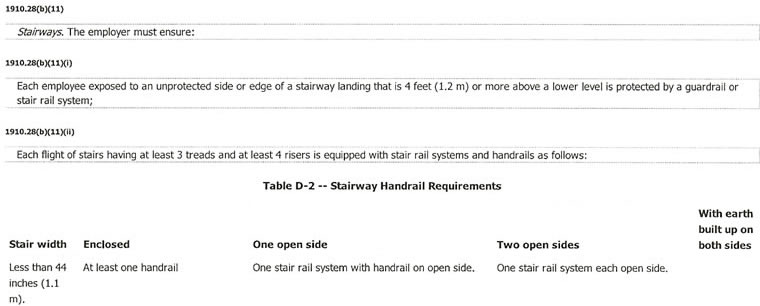

Under

the previous standard, stairs with a handrail that doubles as a stair rail

could have a rail height of 30 to 34

inches. If an employer's stairs were installed prior to January 17, 2017,

must the rails have a minimum height of

36 inches if the stair rail doubles as a handrail? |

The

final rule does not affect stair rail systems and handrails installed before

January 17, 2017 that were in com-

pliance with the requirements in the old standard. |

|

Does

the requirement that standard stairs have a slope between 30 to 50 degrees

apply to stairs installed after January

7, 2017. Therefore, the maximum angle for standard stairs is 45 degrees. |

Yes.

The final rule limits the maximum rise height and minimum tread depth to

9.5 inches for standard stairs installed

after January 17, 2017. Therefore, the maximum angle for standard stairs

is 45 degrees. |

|

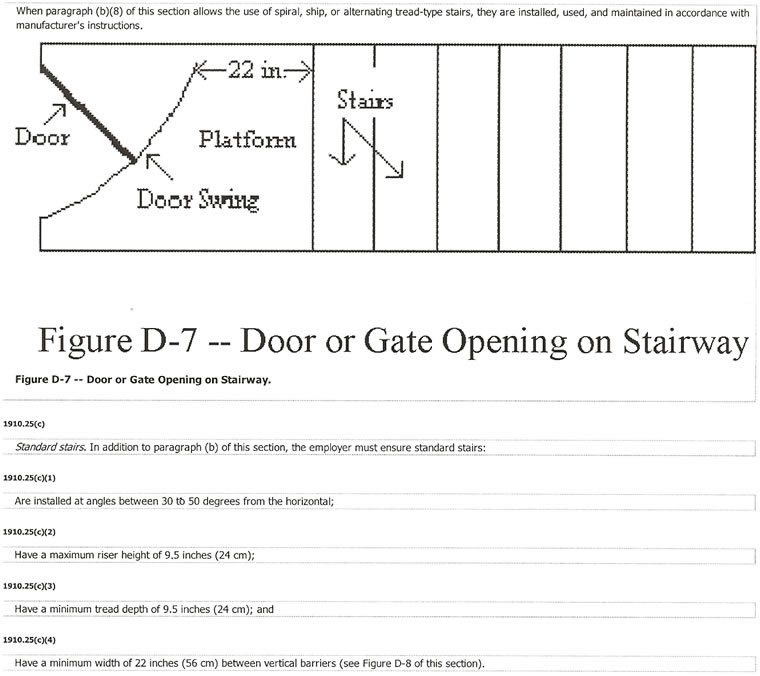

| Are

stairs installed after January 17, 2017, that have an angle of 50 degrees

considered to be ships stairs? |

The

final rule defines ship stairs as “a stairway that is equipped with

treads, stair rails, and open risers, and has a slope

of 50 to 70 degrees.” Ship stairs must also comply with §1910.25(b)

and (e), such as a minimum tread depth of 4

inches, a minimum tread width of 18 inches, and a vertical clearance above

any stair tread to any overhead

obstruction of at least 6 feet 8 inches. |

|

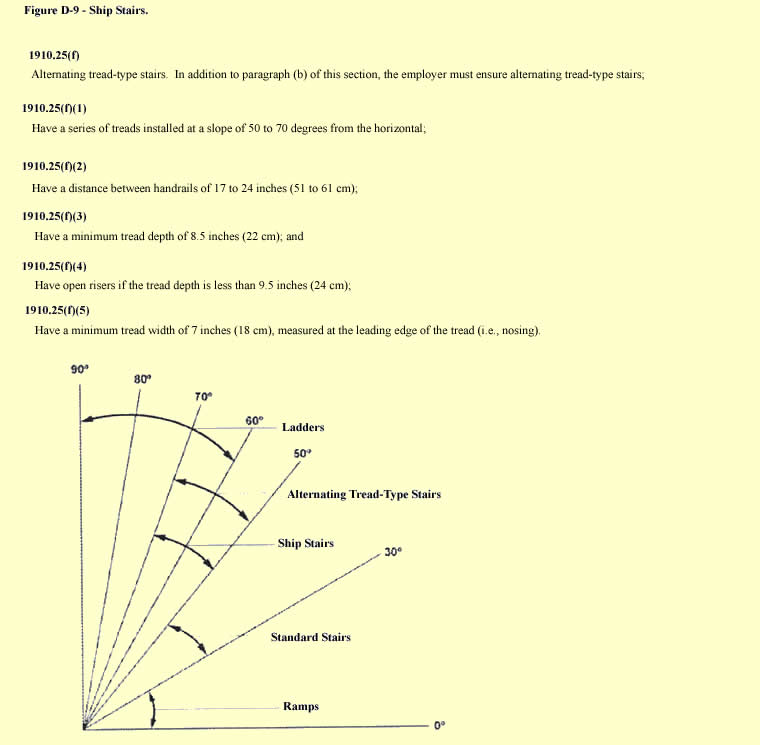

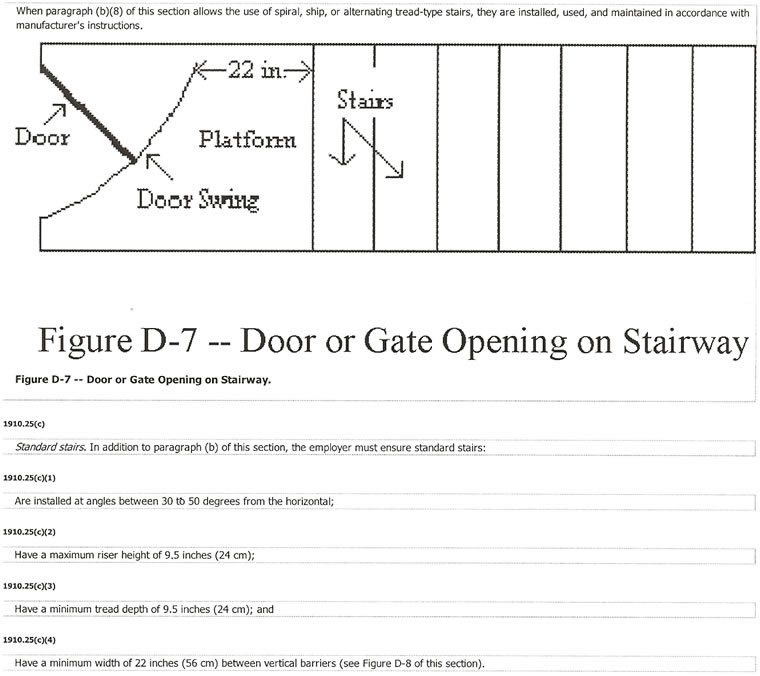

What

if the doorway described in §1910.25(b)(5)(ii) and shown in figure

D-7 is perpendicular to the direction of

travel and opens onto the landing? Does the same dimension apply to this

condition? |

Yes.

As figure D-7 illustrates, Section 1910.25(b)(5) requires that a platform

be provided when a door or a gate opens

directly onto a stairway. For platforms installed after January 17, 2017,

the final rule also requires that employers

ensure the swing of the door or gate does not reduce the "effective

usable depth" of the platform to less than 22 inches (§1910.25(b)(5)(ii)).

The preamble to the final rule describes “effective usable depth”

as the portion of the platform

beyond the swing of the door where a worker can stand when opening the door

(82 FR 82557). The provision applies

equally to stairway doors that are perpendicular to the direction of travel. |

|

Are

fixed stairs attached to the exterior of tanks required to comply with the

requirements of §1910.25(b) or would

those stairs fall under the exemptions in §1910.25(a)?

The exception from the stair requirements in §1910.25(a) only applies

to stairs serving floating roof tanks, stairs on

scaffolds, stairs on self-propelled motorized equipment, or stairs designed

into machines or equipment. For stairs on

the exterior of other tanks, employers would have to ensure they comply

with the requirements in §1910.25(b) and (c). |

|

Would

winding stairs attached to tanks be required to meet the requirements in

§1910.25(d) for spiral stairs?

No. Section 1910.21(b) defines spiral stairs as a "series of treads

attached to a vertical pole in a winding fashion,

usually within a cylindrical space" (emphasis added). Winding stairs

attached to tanks do not have vertical poles;

therefore, they are not spiral stairs and must meet the requirements of

§1910.25(b) and (c). |

|

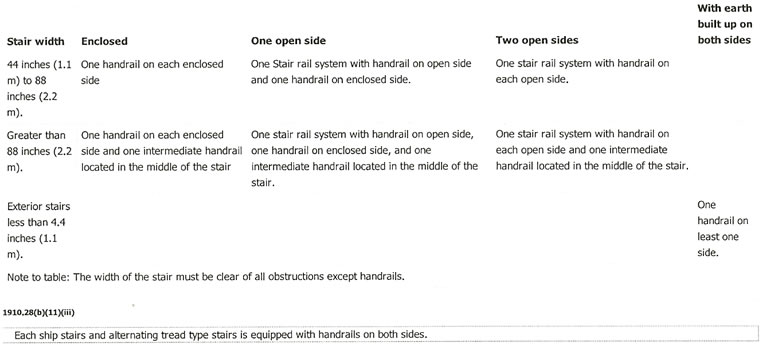

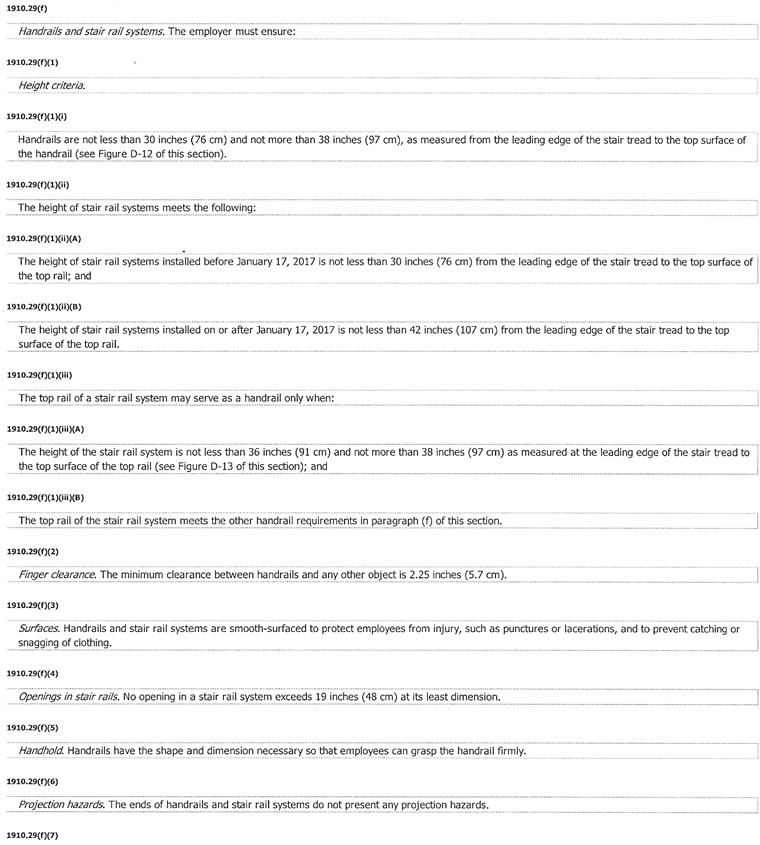

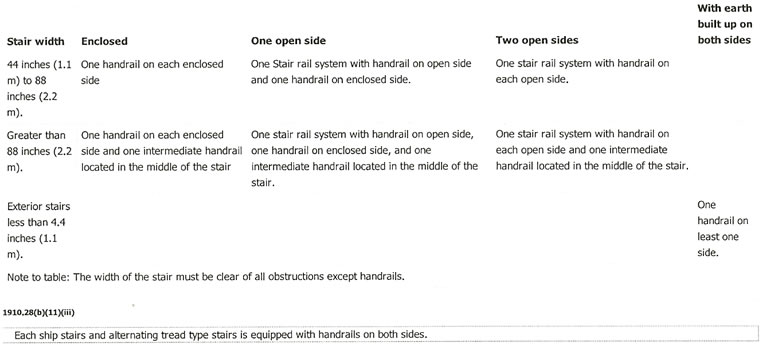

Based

on the height requirements for stair rails and handrails and the requirements

in Table D-2, are both stair rails

and handrails required on stairs that have two open sides and are less than

44-in. wide?

Yes. Section 1910.28(b)(11)(ii) Table D-2 contains a printing error, which

OSHA will correct in a published notice.

For each flight of stairs with two open sides and a width of less than 44

inches, column 4 of Table D-2 should state

"One stair rail system with hand rail on each open side" is required.

(See 81 FR 82611-12). |

|

|

|

|

|

|

Galvanized Stairs, Industrial

Stairs, Metal Stairs, Open Tread Stair, OSHA Prefab Stairways, Outdoor

Steel Stairs, Prefab Metal Stairs,

Prefab Steel Stairs, Prefabricated Stair, Stair Manufacturers, Steel Pan

Stairs, and Steel Stairs from your complete source for material

handling equipment. |

Back

to Product Category |

|

|