|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

MONORAILS

- ENCLOSED TRACK DESIGN

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

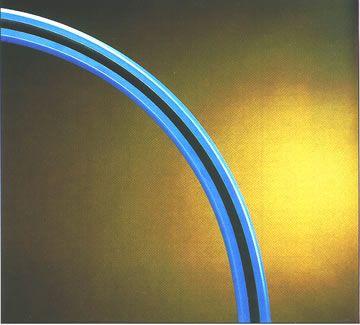

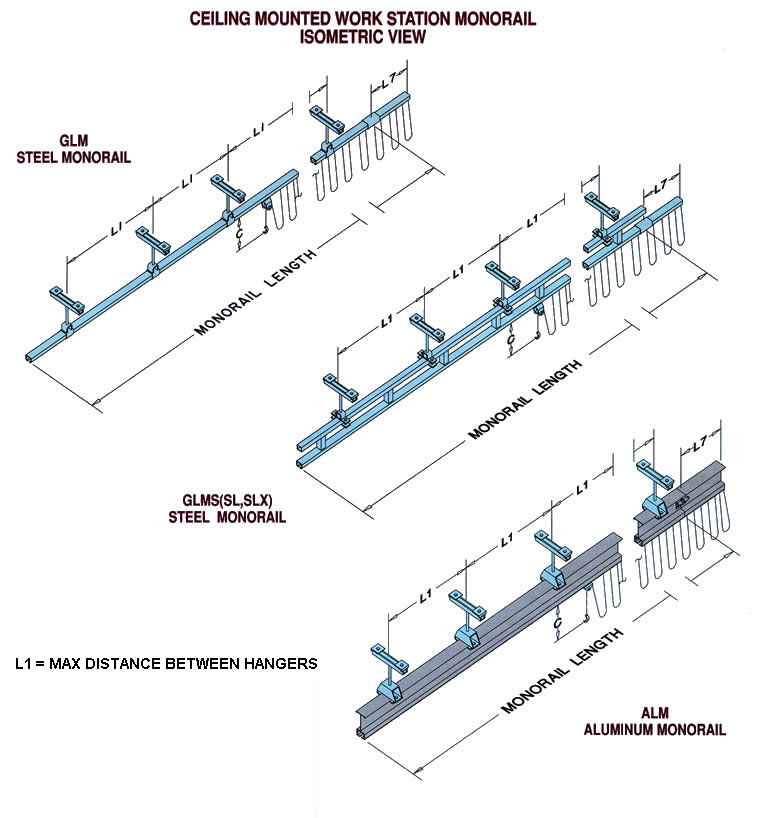

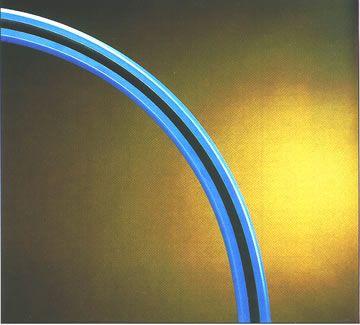

The

2° taper of the running flange

helps to center the trolley in the

track for smooth, effortless

movement of trolleys. |

|

|

|

|

|

|

|

|

|

ENCLOSED

TRACK DESIGN MAKES FOR EASY MOVEMENT AND LONG LIFE |

|

|

|

|

|

Both

the aluminum and steel monorail systems utilize enclosed track that is high

in strength and low in weight.

Major advantages: |

|

|

|

|

|

| •

Enclosed track monorails are easier to move that traditional structural

designs. |

|

|

|

|

|

•

The design virtually eliminates dirt and dust from the rolling surface,

thus reducing wear on the wheels of the

trolley. |

|

|

|

|

|

| •

The smooth running surface means lower rolling resistance. |

|

|

|

|

|

| •

The low profile of the steel track allows the system to be installed where

headroom is a problem. |

|

|

|

|

|

| •

The low track weight reduces the applied forces exerted on the supporting

structure. |

|

|

|

|

|

•

Long spans allow systems to be installed where hanging points are infrequent

(up to 30 feet with the steel truss

design). |

|

|

|

|

|

| •

Four distinct sizes to track -- 250, 500, 1000, and 2000 series -- enable

you to keep weights and costs to a minimum. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

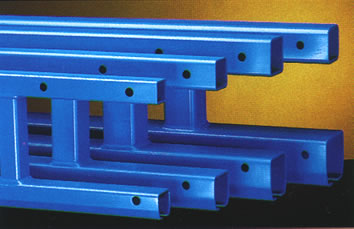

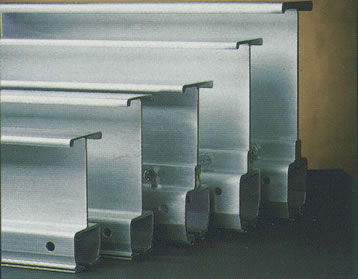

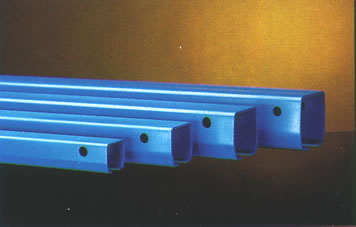

PLAIN

STEEL TRACK: |

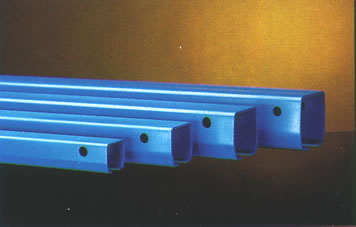

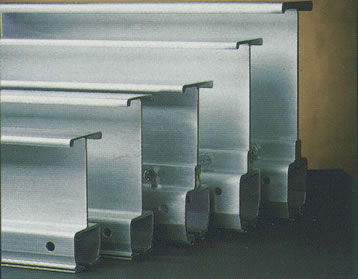

TRUSSED

STEEL TRACK: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For

use where frequent support points are available

or where maximum headroom is required. |

Permits

longer spans when frequent support points

are not available. |

|

|

|

|

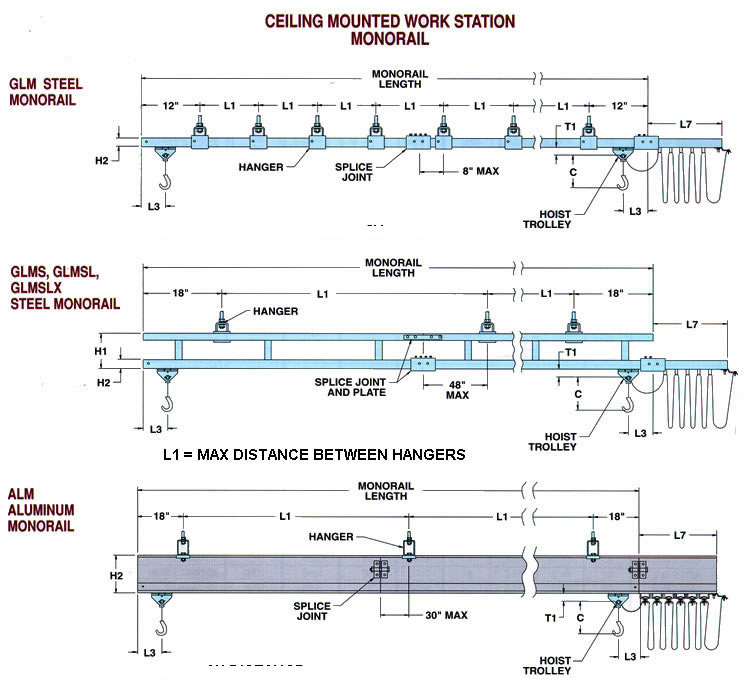

The

standard hot-rolled steel track profile offers a

low-weight to high-strength ratio. Model numbers start

with GLM for this track. |

The

trussed series uses the plain steel track profile

but is enhanced for longer spans via a built-up truss

design. This design increases the span, which

decreases the need for frequent hangers. Model

numbers start with GLMS (for monorails) for spans

up to 20 feet; GLMSL for spans up to 25 feet, and

GLMSLX for spans up to 30 feet. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

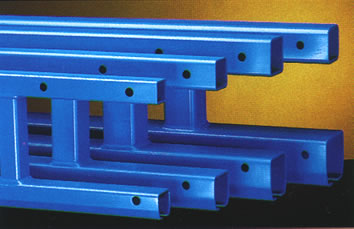

ALUMINUM

TRACK: |

|

|

|

|

For

use where easier movement is required. |

|

The

patented shape of aluminum enclosed track

provides for low weight, unparalleled spanning

capability, and effortless movement. The low weight

(up to 44% less than trussed steel track) results in

easier movement, which makes for safe, productive, ergonomic work cells.

Model numbers start with

ALM (for monorails). |

|

|

|

|

|

|

ANATOMY

OF A MONORAIL |

|

|

|

|

|

|

|

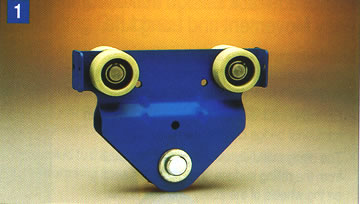

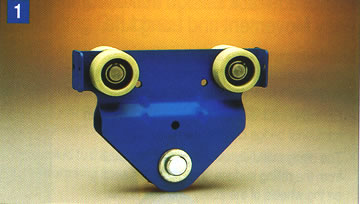

1 |

|

HOIST

TROLLEYS |

|

|

Hoist

trolleys provide the connection between the lifting

device and the monorail. The trolleys are designed for

effortless movement along the track. The stamped body

fits most rigid hook or eye lifting devices. |

|

•

Wheels are tapered to match the 2° taper of the track.

This reduces rolling resistance and wheel wear. Wheels

contain ball bearings that are sealed and lubricated for

life.

• Trolleys are designed to operate in temperatures from

+5° F to +200° F.

• All trolleys meet or exceed the ANSI B30.11

specification for underhung bridge cranes. |

|

|

|

|

|

|

|

|

|

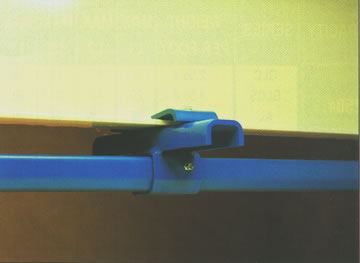

2 |

|

FESTOON

GLIDES |

|

|

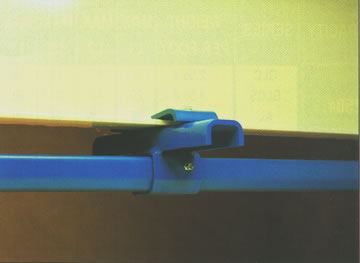

Festoon

gliders are used to support flat cable along the

monorail, and they are standard on monorails of 63 feet

or less. No tools are required to attach the festooning to

the gliders. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

FESTOON

TROLLEYS |

|

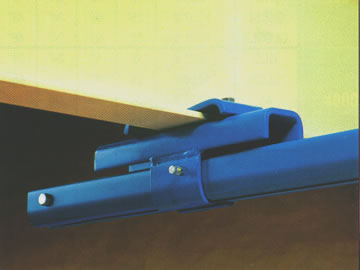

Festoon

trolleys (optional) are used to support flat cable

or air hose along the monorail. The trolleys have four

wheels and a pivoting festoon saddle support. They are

ideally suited for long runways (greater than 63 feet) or

with round cable or air hose. With monorails greater than

63 feet or with an all aluminum system, festoon trolleys

are standard. Special festoon trolleys for vacuum hose

are also available. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

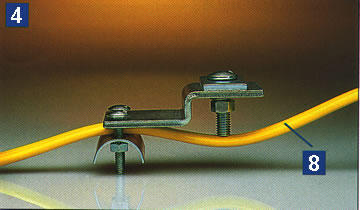

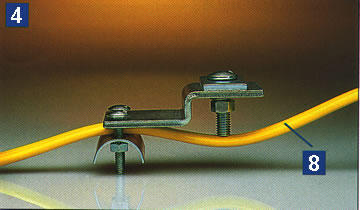

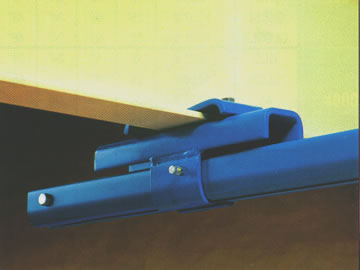

4 |

|

FESTOON

CLAMPS |

|

Festoon

clamps anchor the festooning at the start of the

monorail. They also prevent the festoon gliders from

exiting the track and they can provide a redundant stop

of the trolley. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

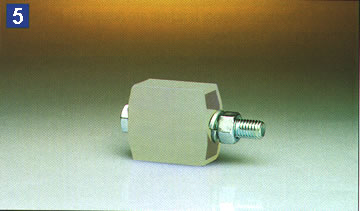

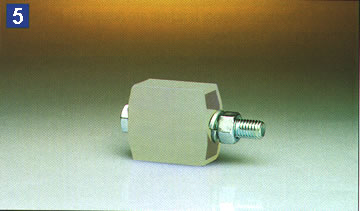

5 |

|

END

STOP BUMPERS |

|

High-impact

molded end stop bumpers are provided on

all monorails, to prevent the trolley from exiting the

track. The bumpers are bolted to the track to physically

limit the travel of the trolley. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

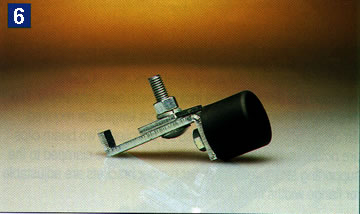

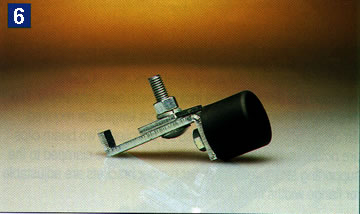

6 |

|

UNIVERSAL

BUMPERS |

|

A

universal bumper can be used as a secondary end

stop, either internally or externally. |

|

|

|

|

|

|

|

|

|

|

|

7 |

|

STACK

SECTIONS |

|

A

stack section at one end of a monorail serves as an

extension that allows festoon carriers to be stored on the

end of the monorail without reducing hoist coverage. |

|

|

|

|

|

8 |

|

FLAT

CABLE AND/OR AIR HOSE |

|

A

flat cable festooning system is included in all

monorails. Plenty of cable is provided for 3 foot loops

on the monorail.

Optional air hose is also available and is supported by

optional festoon trolleys. |

|

|

|

|

|

|

|

9 |

|

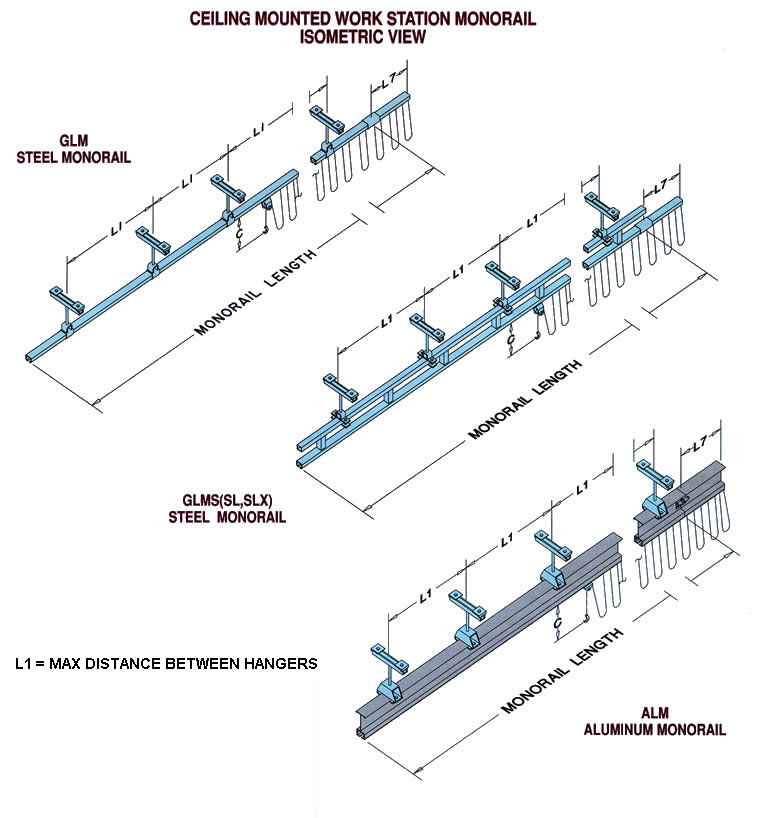

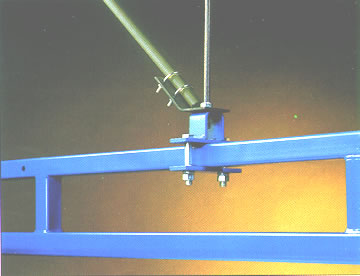

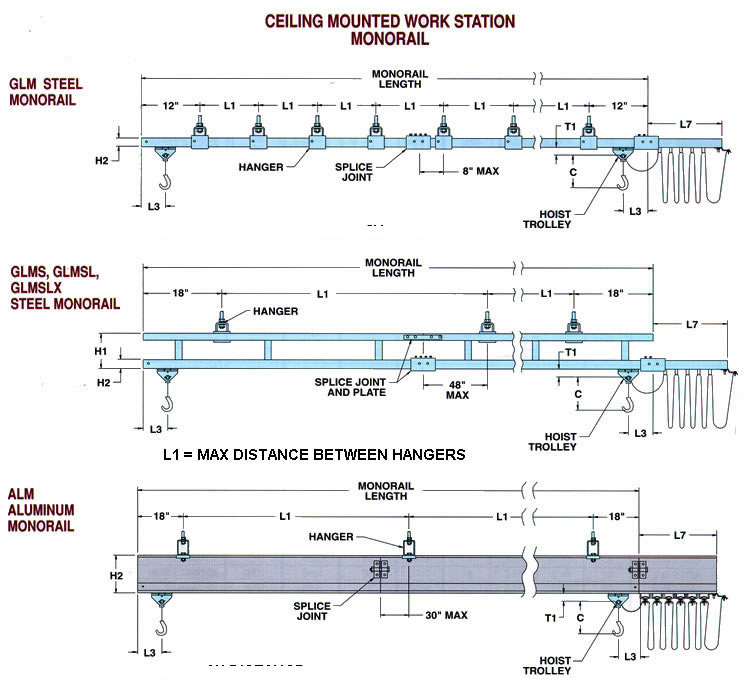

HANGER

ASSEMBLIES |

|

Each

monorail is provided with the number of standard

hanger assemblies listed, based on the maximum "L1"

spacing shown in this page. Sway bracing is required

on all systems, except flush-mounted systems. Sway

bracing kits are not included in the monorail kit (see

Sway Brace Fitting caption on this page). |

|

|

|

|

|

Standard

Hangers for Plain Steel Track |

|

|

|

|

Standard

Hangers - Plain Steel Track |

|

|

|

|

|

Standard

hangers for plain steel track, with a 20 inch

threaded rod (B7 alloy), are included with each

assembly. The threaded rod can be field cut to custom

lengths as required. An optional 72 inch rod can also be

supplied. Two beam clips are bolted to the upper hanger

bracket and are clamped to the supporting structure. The

upper hanger brackets are adjustable for flange widths

from 1 to 10 inches. |

|

|

|

|

|

|

|

|

|

Standard

Hangers for Trussed Steel Track |

|

|

|

|

|

Standard

hangers for trussed steel track, with a 20 inch

threaded rod (B7 alloy), are included with each

assembly. The threaded rod can be field cut to custom

lengths as required. An optional 72 inch rod can also be

supplied. Two beam clips are bolted to the upper hanger

bracket and are clamped to the supporting structure. The

upper hanger brackets are adjustable for flange widths

from 1 to 10 inches. |

Standard

Hangers - Trussed Steel Track |

|

|

|

|

|

|

|

|

|

|

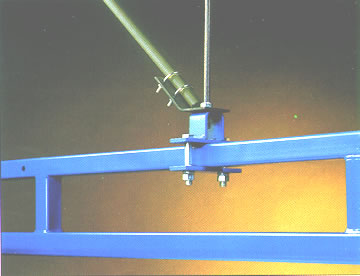

Standard

Hangers for Aluminum Track |

|

|

|

|

|

Standard

hangers for aluminum track, with a 20 inch

threaded rod (B7 alloy), are included with each

assembly. The threaded rod can be field cut to custom

lengths as required. An optional 72 inch rod can also be

supplied. Two beam clips are bolted to the upper hanger

bracket and are clamped to the supporting structure. The

upper hanger brackets are adjustable for flange widths

from 1 to 10 inches. |

Standard

Hangers - Aluminum Track |

|

|

|

|

|

|

|

|

|

|

SWAY

BRACING FITTING |

|

|

|

|

|

(Not

supplied as standard) see options below. |

|

|

|

|

|

Sway

bracing is required on all systems except flush

mounted systems to provide for a rigid-mount runway

that allows the trolley to move freely. The fittings permit

easy sway bracing with 1 inch standard steel pipe (pipe

optional below). The flange is drilled to accept a 5/8 inch

bolt (bolt by others) with two U-bolts (furnished). |

|

|

|

|

Sway

Bracing Fitting |

|

|

|

|

|

|

|

|

|

|

|

FLUSH-MOUNTED

HANGERS -

PARALLEL MOUNT |

|

|

|

|

An

optional ceiling-support bracket, with beam clips,

can be provided for plain track series that require flush

mounting. With this bracket, the track is mounted

underneath, parallel to the supporting steel. Two beam

clips are bolted to the hanger bracket and are clamped

to the supporting structure. When using this style, care

should be taken to determine if the monorail has

adequate overhead clearance. Note: to order this

bracket, the flange width of the supporting structure

must be supplied. |

|

|

|

Flush-Mounted

Hangers - Parallel |

|

|

|

|

|

|

|

|

|

|

|

|

FLUSH-MOUNTED

HANGERS -

PERPENDICULAR MOUNT |

|

|

|

|

An

optional ceiling-support bracket, with beam clips,

can be provided for plain track series that require flush

mounting. With this bracket, the track is mounted

underneath, perpendicular to the supporting steel. Four

beam clips are bolted to the hanger bracket and are

clamped to the supporting structure. When using this

style, care should be taken to determine if the monorail

has adequate overhead clearance. Note: to order this

bracket, the flange width of the supporting structure

must be supplied. |

|

|

|

Flush-Mounted

Hangers - Perpendicular |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

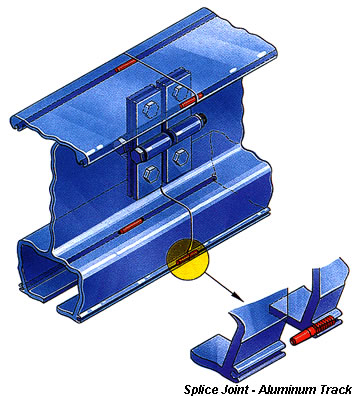

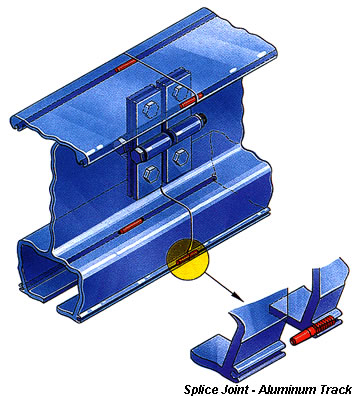

SPLICE

JOINTS FOR

ALUMINUM TRACK |

SPLICE

JOINTS FOR

STEEL TRACK |

|

|

|

|

|

Patented

splice joints for aluminum track allow for

precision alignment. The aluminum track is extruded

with four patented alignment slots. Four precision-

ground pins are provided to accurately align runway

sections, which provides for a smoother transition of

wheels over the spice joint than is possible with bolted

connections. In addition, clamp fasteners attach to the

vertical web of the track to pull the track together and

keep it from separating. |

|

|

A

splice joint is used to join track sections together

and enable the installer to quickly and properly align

the joined sections of track. Adjusting bolts are

provided on the splice joint for leveling and aligning. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

PRICING

- 250# CEILING MOUNTED WORK STATION - MONORAILS |

|

Price

includes: monorail track, hoist trolley, end stops, flat wire festooning,

festoon gliders (festoon trolleys

on steel monorail lengths greater than 63' and all aluminum systems), festoon

stack-up section, splice joints and

hanger brackets. Sway bracing is required on all systems except flush mounted

systems. Sway bracing kits are

available but are not included in the monorail kit. |

|

| 250 # CAPACITY |

| MODEL NO. |

WEIGHT (LBS) |

MONORAIL

(L) |

TRACK

MATL. |

MAX

L1 |

T1

IN. |

H1

IN |

H2

IN. |

L3

IN |

L7

IN |

HANGERS

(see note)* |

PRICE |

| GLM250-11.5 |

102 |

11' 6" |

Steel |

6' |

1-1/2 |

- |

1-3/4 |

5 |

9 |

3 @ 365# |

$1,246 |

| GLMS250-11.5 |

115 |

Steel |

20' |

1-1/2 |

9 |

1-3/4 |

5 |

9 |

2 @ 446# |

$1,282 |

| ALM250-11.5 |

178 |

Alum. |

20' |

2-5/8 |

- |

8 |

7-1/4 |

9 |

2 @ 430# |

$1,998 |

| GLM250-23 |

128 |

23' |

Steel |

6' |

1-1/2 |

- |

1-3/4 |

5 |

9 |

5 @ 365# |

$1,684 |

| GLMS250-23 |

127 |

Steel |

20' |

1-1/2 |

9 |

1-3/4 |

5 |

9 |

2 @ 446# |

$1,785 |

| ALM250-23 |

217 |

Alum. |

20' |

2-5/8 |

- |

8 |

7-1/4 |

13 |

2 @ 430# |

$2,196 |

| GLMSL250-28 |

238 |

28' |

Steel |

25' |

1-1/2 |

11 |

1-3/4 |

5 |

9 |

2 @ 554# |

$2,526 |

| GLM250-33 |

159 |

33' |

Steel |

6' |

1-1/2 |

- |

1-3/4 |

5 |

9 |

7 @ 365# |

$2,345 |

| GLMS250-33 |

166 |

Steel |

20' |

1-1/2 |

9 |

1-3/4 |

5 |

9 |

3 @ 446# |

$2,633 |

| ALM250-33 |

257 |

Alum. |

20' |

2-5/8 |

- |

8 |

7-1/4 |

19 |

3 @ 430# |

$3,279 |

| GLM250-43 |

234 |

43' |

Steel |

6' |

1-1/2 |

- |

1-3/4 |

5 |

13 |

9 @ 365# |

$2,850 |

| GLMS250-43 |

259 |

Steel |

20' |

1-1/2 |

9 |

1-3/4 |

5 |

13 |

3 @ 446# |

$3,070 |

| ALM250-43 |

292 |

Alum. |

20' |

2-5/8 |

- |

8 |

7-1/4 |

26 |

3 @ 430# |

$3,882 |

| GLM250-53 |

301 |

53' |

Steel |

6' |

1-1/2 |

- |

1-3/4 |

5 |

13 |

11 @ 365# |

$3,505 |

| GLMS250-53 |

319 |

Steel |

20' |

1-1/2 |

9 |

1-3/4 |

5 |

13 |

4 @ 446# |

$3,913 |

| ALM250-53 |

331 |

Alum. |

20' |

2-5/8 |

- |

8 |

7-1/4 |

30 |

4 @ 430# |

$4,932 |

| GLMSL250-53 |

454 |

Steel |

25' |

1-1/2 |

11 |

1-3/4 |

5 |

13 |

3 @ 554# |

$4,524 |

| GLM250-63 |

376 |

63' |

Steel |

6' |

1-1/2 |

- |

1-3/4 |

5 |

19 |

13 @ 365# |

$4,012 |

| GLMS250-63 |

412 |

Steel |

20' |

1-1/2 |

9 |

1-3/4 |

5 |

19 |

3 @ 446# |

$4,352 |

| ALM250-63 |

366 |

Alum. |

20' |

2-5/8 |

- |

8 |

7-1/4 |

36 |

3 @ 430# |

$5,527 |

| GLMSL250-78 |

671 |

78' |

Steel |

25' |

1-1/2 |

11 |

1-3/4 |

5 |

46 |

4 @ 554# |

Call |

| GLM250-83 |

428 |

83' |

Steel |

6' |

1-1/2 |

- |

1-3/4 |

5 |

46 |

17 @ 365# |

Call |

| GLMS250-83 |

472 |

Steel |

20' |

1-1/2 |

9 |

1-3/4 |

5 |

46 |

5 @ 446# |

Call |

| ALM250-83 |

440 |

Alum. |

20' |

2-5/8 |

- |

8 |

7-1/4 |

46 |

5 @ 430# |

Call |

| GLM250-103 |

500 |

103' |

Steel |

6' |

1-1/2 |

- |

1-3/4 |

5 |

54 |

24 @ 365# |

Call |

| GLMS250-103 |

558 |

Steel |

20' |

1-1/2 |

9 |

1-3/4 |

5 |

54 |

6 @ 446# |

Call |

| ALM250-103 |

515 |

Alum. |

20' |

2-5/8 |

- |

8 |

7-1/4 |

54 |

6 @ 430# |

Call |

| GLMSL250-103 |

888 |

Steel |

25' |

1-1/2 |

11 |

1-3/4 |

5 |

54 |

5 @ 554# |

Call |

|

NOTE: *This column provides the total number of support

hangers with the corresponding vertical load applied by

each support hanger (in pounds) based on the "L1" dimension shown

Up to a 20" hanger drop will be provided.

Additional hanger points or longer drops can be provided at an additional

charge. |

|

| PRICING

- 500# CEILING MOUNTED WORK STATION - MONORAILS |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

Price

includes: monorail track, hoist trolley, end stops, flat wire festooning,

festoon gliders (festoon trolleys

on steel monorail lengths greater than 63' and all aluminum systems), festoon

stack-up section, splice joints and

hanger brackets. Sway bracing is required on all systems except flush mounted

systems. Sway bracing kits are

available but are not included in the monorail kit. |

|

| 500 # CAPACITY |

MODEL

NO. |

WEIGHT

(LBS) |

MONORAIL

(L) |

TRACK

MATL. |

MAX

L1 |

T1

IN. |

H1

IN |

H2

IN. |

L3

IN |

L7

IN |

HANGERS

(see note)* |

PRICE |

| GLM500-11.5 |

127 |

11' 6" |

Steel |

6' |

2-3/4 |

- |

2-3/8 |

7-1/8 |

9 |

3 @ 725# |

$1,425 |

| GLMS500-11.5 |

148 |

Steel |

20' |

2-3/4 |

10 |

2-3/8 |

7-1/8 |

9 |

2 @ 845# |

$1,471 |

| ALM500-11.5 |

200 |

Alum. |

20' |

2-5/8 |

- |

10 |

7-1/4 |

9 |

2 @ 794# |

$2,360 |

| GLM500-23 |

181 |

23' |

Steel |

6' |

2-3/4 |

- |

2-3/8 |

7-1/8 |

9 |

5 @ 725# |

$1,947 |

| GLMS500-23 |

199 |

Steel |

20' |

2-3/4 |

10 |

2-3/8 |

7-1/8 |

9 |

2 @ 845# |

$2,125 |

| ALM500-23 |

264 |

Alum. |

20' |

2-5/8 |

- |

10 |

7-1/4 |

13 |

2 @ 794# |

$2,570 |

| GLMSL500-28 |

312 |

28' |

Steel |

25' |

2-3/4 |

12-3/8 |

2-3/8 |

7-1/8 |

9 |

2 @ 943# |

$2,800 |

| GLM500-33 |

240 |

33' |

Steel |

6' |

2-3/4 |

- |

2-3/8 |

7-1/8 |

9 |

7 @ 725# |

$2,715 |

| GLMS500-33 |

261 |

Steel |

20' |

2-3/4 |

10 |

2-3/8 |

7-1/8 |

9 |

3 @ 845# |

$3,134 |

| ALM500-33 |

322 |

Alum. |

20' |

2-5/8 |

- |

10 |

7-1/4 |

19 |

3 @ 794# |

$3,824 |

| GLMSLX500-34 |

356 |

34' |

Steel |

30' |

2-3/4 |

14-3/8 |

2-3/8 |

7-1/8 |

9 |

2 @ 991# |

$3,267 |

| GLM500-43 |

347 |

43' |

Steel |

6' |

2-3/4 |

- |

2-3/8 |

7-1/8 |

13 |

9 @ 725# |

$3,283 |

| GLMS500-43 |

395 |

Steel |

20' |

2-3/4 |

10 |

2-3/8 |

7-1/8 |

13 |

3 @ 845# |

$3,732 |

| ALM500-43 |

379 |

Alum. |

20' |

2-5/8 |

- |

|

7-1/4 |

26 |

3 @ 794# |

$4,608 |

| GLM500-53 |

441 |

53' |

Steel |

6' |

2-3/4 |

- |

2-3/8 |

7-1/8 |

13 |

11 @ 725# |

$4,046 |

| GLMS500-53 |

488 |

Steel |

20' |

2-3/4 |

10 |

2-3/8 |

7-1/8 |

13 |

4 @ 845# |

$4,738 |

| ALM500-53 |

436 |

Alum. |

20' |

2-5/8 |

- |

10 |

7-1/4 |

30 |

4 @ 794# |

$5,831 |

| GLMSL500-53 |

598 |

Steel |

25' |

2-3/4 |

12-3/8 |

2-3/8 |

7-1/8 |

13 |

3 @ 943# |

$5,249 |

| GLM500-63 |

548 |

63' |

Steel |

6' |

2-3/4 |

- |

2-3/8 |

7-1/8 |

19 |

23 @ 725# |

$4,611 |

| GLMS500-63 |

604 |

Steel |

20' |

2-3/4 |

10 |

2-3/8 |

7-1/8 |

19 |

4 @ 845# |

$5,334 |

| ALM500-63 |

493 |

Alum. |

20' |

2-5/8 |

- |

10 |

7-1/4 |

36 |

4 @ 794# |

$6,610 |

| GLMSLX500-64 |

650 |

64' |

Steel |

30' |

2-3/4 |

14-3/8 |

2-3/8 |

7-1/8 |

36 |

3 @ 991# |

$6,225 |

| GLMSL500-78 |

883 |

78' |

Steel |

25' |

2-3/4 |

12-3/8 |

2-3/8 |

7-1/8 |

46 |

4 @ 943# |

Call |

| GLM500-83 |

626 |

83' |

Steel |

6' |

2-3/4 |

- |

2-3/8 |

7-1/8 |

46 |

17 @ 725# |

Call |

| GLMS500-83 |

714 |

Steel |

20' |

2-3/4 |

10 |

2-3/8 |

7-1/8 |

46 |

5 @ 845# |

Call |

| ALM500-83 |

607 |

Alum. |

20' |

2-5/8 |

- |

10 |

7-1/4 |

46 |

5 @ 794# |

Call |

| GLMSLX500-94 |

961 |

94' |

Steel |

30' |

2-3/4 |

14-3/8 |

2-3/8 |

7-1/8 |

54 |

4 @ 991# |

Call |

| GLM500-103 |

708 |

103' |

Steel |

6' |

2-3/4 |

- |

2-3/8 |

7-1/8 |

54 |

24 @ 725# |

Call |

| GLMS500-103 |

819 |

Steel |

20' |

2-3/4 |

10 |

2-3/8 |

7-1/8 |

54 |

6 @ 845# |

Call |

| ALM500-103 |

722 |

Alum. |

20' |

2-5/8 |

- |

10 |

7-1/4 |

54 |

6 @ 794# |

Call |

| GLMSL500-103 |

1168 |

Steel |

25' |

2-3/4 |

12-3/8 |

2-3/8 |

7-1/8 |

54 |

5 @ 943# |

Call |

| GLMSLX500-124 |

1272 |

124' |

Steel |

30' |

2-3/4 |

14-3/8 |

2-3/8 |

7-1/8 |

54 |

5 @ 991# |

Call |

|

NOTE: *This column provides the total number of support

hangers with the corresponding vertical load applied by

each support hanger (in pounds) based on the "L1" dimension shown

Up to a 20" hanger drop will be provided.

Additional hanger points or longer drops can be provided at an additional

charge. |

|

| PRICING

- 1000# CEILING MOUNTED WORK STATION - MONORAILS |

|

Price

includes: monorail track, hoist trolley, end stops, flat wire festooning,

festoon gliders (festoon trolleys

on steel monorail lengths greater than 63' and all aluminum systems), festoon

stack-up section, splice joints

and hanger brackets. Sway bracing is required on all systems except flush

mounted systems. Sway bracing

kits are available but are not included in the monorail kit. |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

| 1000 # CAPACITY |

MODEL

NO. |

WEIGHT

(LBS) |

MONORAIL

(L) |

TRACK

MATL. |

MAX

L1 |

T1

IN. |

H1

IN |

H2

IN. |

L3

IN |

L7

IN |

HANGERS

(see note)* |

PRICE |

| GLM1000-11.5 |

165 |

11' 6" |

Steel |

6' |

3 |

- |

3 |

7-7/8 |

9 |

3 @ 1451# |

$2,092 |

| GLMS1000-11.5 |

216 |

Steel |

20' |

3 |

11 |

3 |

7-7/8 |

9 |

2 @ 1679# |

$1,885 |

| ALM1000-11.5 |

236 |

Alum. |

20' |

2-7/8 |

- |

11 |

7-7/8 |

9 |

2 @ 1567# |

$3,032 |

| GLM1000-23 |

211 |

23' |

Steel |

6' |

3 |

- |

3 |

7-7/8 |

9 |

5 @ 1451# |

$2,679 |

| GLMS1000-23 |

278 |

Steel |

20' |

3 |

11 |

3 |

7-7/8 |

9 |

2 @ 1679# |

$2,680 |

| ALM1000-23 |

335 |

Alum. |

20' |

2-7/8 |

- |

11 |

7-7/8 |

13 |

2 @ 1567# |

$3,425 |

| GLMSL1000-28 |

505 |

28' |

Steel |

25' |

3 |

13-7/8 |

3 |

7-7/8 |

13 |

2 @ 1781# |

$3,178 |

| GLM1000-33 |

304 |

33' |

Steel |

6' |

3 |

- |

3 |

7-7/8 |

13 |

7 @ 1451# |

$3,742 |

| GLMS1000-33 |

375 |

Steel |

20' |

3 |

11 |

3 |

7-7/8 |

13 |

3 @ 1679# |

$3,821 |

| ALM1000-33 |

420 |

Alum. |

20' |

2-7/8 |

- |

11 |

7-7/8 |

19 |

3 @ 1567# |

$4,952 |

| GLMSLX1000-34 |

547 |

34' |

Steel |

30' |

3 |

17 |

3 |

7-7/8 |

13 |

2 @ 1951# |

$3,827 |

| GLM1000-43 |

474 |

43' |

Steel |

6' |

3 |

- |

3 |

7-7/8 |

19 |

9 @ 1451# |

$4,578 |

| GLMS1000-43 |

599 |

Steel |

20' |

3 |

11 |

3 |

7-7/8 |

19 |

3 @ 1679# |

$4,436 |

| ALM1000-43 |

509 |

Alum. |

20' |

2-7/8 |

- |

11 |

7-7/8 |

26 |

3 @ 1567# |

$5,980 |

| GLM1000-53 |

603 |

53' |

Steel |

6' |

3 |

- |

3 |

7-7/8 |

19 |

11 @ 1451# |

$5,635 |

| GLMS1000-53 |

758 |

Steel |

20' |

3 |

11 |

3 |

7-7/8 |

19 |

4 @ 1679# |

$5,569 |

| ALM1000-53 |

594 |

Alum. |

20' |

2-7/8 |

- |

11 |

7-7/8 |

30 |

4 @ 1567# |

$7,476 |

| GLMSL1000-53 |

969 |

Steel |

25' |

3 |

13-7/8 |

3 |

7-7/8 |

19 |

3 @ 1728# |

$5,601 |

| GLM1000-63 |

763 |

63' |

Steel |

6' |

3 |

- |

3 |

7-7/8 |

26 |

13 @ 1451# |

$6,478 |

| GLMS1000-63 |

980 |

Steel |

20' |

3 |

11 |

3 |

7-7/8 |

26 |

4 @ 1679# |

$6,187 |

| ALM1000-63 |

682 |

Alum. |

20' |

2-7/8 |

- |

11 |

7-7/8 |

36 |

4 @ 1567# |

$8,496 |

| GLMSLX1000-64 |

1053 |

64' |

Steel |

30' |

3 |

17 |

3 |

7-7/8 |

36 |

3 @ 1915# |

$7,139 |

| GLMSL1000-78 |

1663 |

78' |

Steel |

25' |

3 |

13-7/8 |

3 |

7-7/8 |

46 |

4 @ 1781# |

Call |

| GLM1000-83 |

884 |

83' |

Steel |

6' |

3 |

- |

3 |

7-7/8 |

46 |

17 @ 1451# |

Call |

| GLMS1000-83 |

1139 |

Steel |

20' |

3 |

11 |

3 |

7-7/8 |

46 |

5 @ 1679# |

Call |

| ALM1000-83 |

856 |

Alum. |

20' |

2-7/8 |

- |

11 |

7-7/8 |

46 |

5 @ 1567# |

Call |

| GLMSLX1000-94 |

1558 |

94' |

Steel |

30' |

3 |

17 |

3 |

7-7/8 |

54 |

4 @ 1915# |

Call |

| GLM1000-103 |

1037 |

103' |

Steel |

6' |

3 |

- |

3 |

7-7/8 |

54 |

24 @ 1451# |

Call |

| GLMS1000-103 |

1344 |

Steel |

20' |

3 |

11 |

3 |

7-7/8 |

54 |

6 @ 1679# |

Call |

| ALM1000-103 |

1030 |

Alum. |

20' |

2-7/8 |

- |

11 |

7-7/8 |

54 |

6 @ 1567# |

Call |

| GLMSL1000-103 |

2203 |

Steel |

25' |

3 |

13-7/8 |

3 |

7-7/8 |

54 |

5 @ 1781# |

Call |

| GLMSLX1000-124 |

2063 |

124' |

Steel |

30' |

3 |

17 |

3 |

7-7/8 |

54 |

5 @ 1915# |

Call |

|

NOTE: *This column provides the total number of support

hangers with the corresponding vertical load applied by

each support hanger (in pounds) based on the "L1" dimension shown

Up to a 20" hanger drop will be provided.

Additional hanger points or longer drops can be provided at an additional

charge. |

|

| PRICING

- 2000# CEILING MOUNTED WORK STATION - MONORAILS |

Price

includes: monorail track, hoist trolley, end stops, flat wire festooning,

festoon gliders (festoon trolleys

on steel monorail lengths greater than 63' and all aluminum systems), festoon

stack-up section, splice joints

and hanger brackets. Sway bracing is required on all systems except flush

mounted systems. Sway bracing

kits are available but are not included in the monorail kit. |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

| 2000 # CAPACITY |

MODEL

NO. |

WEIGHT

(LBS) |

MONORAIL

(L) |

TRACK

MATL. |

MAX

L1 |

T1

IN. |

H1

IN |

H2

IN. |

L3

IN |

L7

IN |

HANGERS

(see note)* |

PRICE |

| GLM2000-11.5 |

241 |

11' 6" |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

8-1/8 |

9 |

3 @ 2894# |

$2,424 |

| GLMS2000-11.5 |

287 |

Steel |

20' |

2-7/8 |

12 |

3-1/2 |

8-1/8 |

9 |

2 @ 3137# |

$2,033 |

| ALM2000-11.5 |

303 |

Alum. |

20' |

2-7/8 |

- |

13-1/4 |

12-7/8 |

9 |

2 @ 3046# |

$3,331 |

| GLM2000-23 |

308 |

23' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

8-1/8 |

9 |

5 @ 2894# |

$3,272 |

| GLMS2000-23 |

378 |

Steel |

20' |

2-7/8 |

12 |

3-1/2 |

8-1/8 |

9 |

2 @ 3137# |

$2,860 |

| ALM2000-23 |

480 |

Alum. |

20' |

2-7/8 |

- |

13-1/4 |

12-7/8 |

13 |

2 @ 3046# |

$3,703 |

| GLMSL2000-28 |

674 |

28' |

Steel |

25' |

2-7/8 |

15-3/8 |

3-1/2 |

8-1/8 |

9 |

2 @ 3308# |

$4,010 |

| GLM2000-33 |

438 |

33' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

8-1/8 |

13 |

7 @ 2894# |

$4,569 |

| GLMS2000-33 |

522 |

Steel |

20' |

2-7/8 |

12 |

3-1/2 |

8-1/8 |

13 |

3 @ 3137# |

$4,189 |

| ALM2000-33 |

620 |

Alum. |

20' |

2-7/8 |

- |

13-1/4 |

12-7/8 |

19 |

3 @ 3046# |

$5,341 |

| GLMSLX2000-34 |

731 |

34' |

Steel |

30' |

2-7/8 |

18 |

3-1/2 |

8-1/8 |

13 |

2 @ 2894# |

$4,174 |

| GLM2000-43 |

656 |

43' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

8-1/8 |

19 |

9 @ 2894# |

$5,701 |

| GLMS2000-43 |

820 |

Steel |

20' |

2-7/8 |

12 |

3-1/2 |

8-1/8 |

19 |

3 @ 3137# |

$4,389 |

| ALM2000-43 |

781 |

Alum. |

20' |

2-7/8 |

- |

13-1/4 |

12-7/8 |

26 |

3 @ 3046# |

$6,440 |

| GLM2000-53 |

855 |

53' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

8-1/8 |

19 |

11 @ 2894# |

$6,814 |

| GLMS2000-53 |

1034 |

Steel |

20' |

2-7/8 |

12 |

3-1/2 |

8-1/8 |

19 |

4 @ 3137# |

$6,247 |

| ALM2000-53 |

919 |

Alum. |

20' |

2-7/8 |

- |

13-1/4 |

12-7/8 |

30 |

4 @ 3046# |

$8,044 |

| GLMSL2000-53 |

1298 |

Steel |

25' |

2-7/8 |

15-3/8 |

3-1/2 |

8-1/8 |

19 |

3 @ 3308# |

$7,219 |

| GLM2000-63 |

1037 |

63' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

8-1/8 |

26 |

13 @ 2894# |

$7,773 |

| GLMS2000-63 |

1331 |

Steel |

20' |

2-7/8 |

12 |

3-1/2 |

8-1/8 |

26 |

4 @ 3137# |

$6,981 |

| ALM2000-63 |

1080 |

Alum. |

20' |

2-7/8 |

- |

13-1/4 |

12-7/8 |

36 |

4 @ 3046# |

$9,139 |

| GLMSLX2000-64 |

1412 |

64' |

Steel |

30' |

2-7/8 |

18 |

3-1/2 |

8-1/8 |

36 |

3 @ 3402# |

$7,808 |

| GLMSL2000-78 |

1921 |

78' |

Steel |

25' |

2-7/8 |

15-3/8 |

3-1/2 |

8-1/8 |

46 |

4 @ 3308# |

Call |

| GLM2000-83 |

1231 |

83' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

8-1/8 |

46 |

17 @ 2894# |

Call |

| GLMS2000-83 |

1525 |

Steel |

20' |

2-7/8 |

12 |

3-1/2 |

8-1/8 |

46 |

5 @ 3137# |

Call |

| ALM2000-83 |

1379 |

Alum. |

20' |

2-7/8 |

- |

13-1/4 |

12-7/8 |

46 |

5 @ 3046# |

Call |

| GLMSLX2000-94 |

2092 |

94' |

Steel |

30' |

2-7/8 |

18 |

3-1/2 |

8-1/8 |

54 |

4 @ 3402# |

Call |

| GLM2000-103 |

1407 |

103' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

8-1/8 |

54 |

24 @ 2894# |

Call |

| GLMS2000-103 |

1771 |

Steel |

20' |

2-7/8 |

12 |

3-1/2 |

8-1/8 |

54 |

6 @ 3137# |

Call |

| ALM2000-103 |

1680 |

Alum. |

20' |

2-7/8 |

- |

13-1/4 |

12-7/8 |

54 |

6 @ 3046# |

Call |

| GLMSL2000-103 |

2544 |

Steel |

25' |

2-7/8 |

15-3/8 |

3-1/2 |

8-1/8 |

54 |

5 @ 3308# |

Call |

| GLMSLX2000-124 |

2772 |

124' |

Steel |

30' |

2-7/8 |

18 |

3-1/2 |

8-1/8 |

54 |

5 @ 3402# |

Call |

|

NOTE: *This column provides the total number of support

hangers with the corresponding vertical load applied by

each support hanger (in pounds) based on the "L1" dimension shown

Up to a 20" hanger drop will be provided.

Additional hanger points or longer drops can be provided at an additional

charge. |

|

| PRICING

- 4000# CEILING MOUNTED WORK STATION - MONORAILS |

|

Price

includes: monorail track, hoist trolley, end stops, flat wire festooning,

festoon gliders (festoon trolleys

on steel monorail lengths greater than 63' and all aluminum systems), festoon

stack-up section, splice joints

and hanger brackets. Sway bracing is required on all systems except flush

mounted systems. Sway bracing

kits are available but are not included in the monorail kit. |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

| 4000 # CAPACITY |

| MODEL NO. |

WEIGHT

(LBS) |

MONORAIL

(L) |

TRACK

MATL. |

MAX

L1 |

T1

IN. |

H1

IN |

H2

IN. |

L3 IN |

L7

IN |

HANGERS

(see note)* |

PRICE |

| GLM4000-23 |

763 |

23' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

15-1/8 |

9 |

5 @ 5664# |

$3,997 |

| GLMS4000-23 |

872 |

Steel |

20' |

2-7/8 |

18 |

3-1/2 |

15-1/8 |

9 |

2 @ 5995# |

$5,160 |

| GLMSL4000-28 |

1013 |

28' |

Steel |

25' |

2-7/8 |

20 |

3-1/2 |

15-1/8 |

13 |

2 @ 6093# |

$5,709 |

| GLM4000-33 |

1116 |

33' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

15-1/8 |

13 |

7 @ 5664# |

$6,181 |

| GLMS4000-33 |

1173 |

Steel |

20' |

2-7/8 |

18 |

3-1/2 |

15-1/8 |

13 |

3 @ 5995# |

$7,484 |

| GLM4000-43 |

1316 |

43' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

15-1/8 |

19 |

9 @ 5664# |

$7,006 |

| GLMS4000-43 |

1332 |

Steel |

20' |

2-7/8 |

18 |

3-1/2 |

15-1/8 |

19 |

3 @ 5995# |

$8,335 |

| GLM4000-53 |

1499 |

53' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

15-1/8 |

19 |

11 @ 5664# |

$8,528 |

| GLMS4000-53 |

1663 |

Steel |

20' |

2-7/8 |

18 |

3-1/2 |

15-1/8 |

19 |

4 @ 5995# |

$10,677 |

| GLMSL4000-53 |

1866 |

Steel |

25' |

2-7/8 |

20 |

3-1/2 |

15-1/8 |

19 |

3 @ 6093# |

$9,890 |

| GLM4000-63 |

1799 |

63' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

15-1/8 |

26 |

13 @ 5664# |

$9,604 |

| GLMS4000-63 |

1991 |

Steel |

20' |

2-7/8 |

18 |

3-1/2 |

15-1/8 |

26 |

4 @ 5995# |

$11,440 |

| GLMSL4000-78 |

2718 |

78' |

Steel |

25' |

2-7/8 |

20 |

3-1/2 |

15-1/8 |

46 |

4 @ 6093# |

Call |

| GLM4000-83 |

2212 |

83' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

15-1/8 |

46 |

17 @ 5664# |

Call |

| GLMS4000-83 |

2550 |

Steel |

20' |

2-7/8 |

18 |

3-1/2 |

15-1/8 |

46 |

5 @ 5995# |

Call |

| GLM4000-103 |

2695 |

103' |

Steel |

6' |

2-7/8 |

- |

3-1/2 |

15-1/8 |

54 |

21 @ 5664# |

Call |

| GLMS4000-103 |

3110 |

Steel |

20' |

2-7/8 |

18 |

3-1/2 |

15-1/8 |

54 |

6 @ 5995# |

Call |

| GLMSL4000-103 |

3570 |

Steel |

25' |

2-7/8 |

20 |

3-1/2 |

15-1/8 |

54 |

5 @ 6093# |

Call |

|

NOTE: *This column provides the total number of support

hangers with the corresponding vertical load applied by

each support hanger (in pounds) based on the "L1" dimension shown

Up to a 20" hanger drop will be provided.

Additional hanger points or longer drops can be provided at an additional

charge. |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

OPTIONS |

|

|

|

|

|

| PRICING

- SWAY BRACE FITTING |

|

|

|

|

|

|

|

|

|

|

|

|

| MODEL NO. |

WEIGHT |

PRICE |

| B-562 |

1# |

$26.30 |

|

|

|

|

|

|

|

These

clamps permit easy sway bracing with 1" outside diameter standard pipe

(pipe by

others). Clamps have a black zinc finish. Mounting hole in fitting is drilled

to accept 5/8"

mounting bolt (bolt by others). U-bolts are furnished. These fittings are

NOT INCLUDED

with monorail kit. |

|

|

|

|

|

|

|

|

|

| PRICING

- SWAY BRACE PIPE AND ANGLE |

|

|

|

|

|

|

|

|

|

Now

we offer sway brace pipe and angle as

components that can be added to your Ceiling

Mounted Work Station Crane order. Both pipe

and angle can be ordered in CraneBrain™ or by

contacting us. They are constructed of unpainted

steel and are available in the lengths shown below. |

|

|

|

|

|

|

|

SWAY BRACE PIPE |

| Model No. |

Description |

Length |

Weight |

Price |

|

1" SCH40 |

10'-6" |

18# |

$49.30 |

|

1" SCH40 |

21'-0" |

35# |

$103.53 |

|

1" SCH80 |

21'-0" |

46# |

$190.63 |

|

|

|

SWAY BRACE ANGLE |

| Model No. |

Description |

Length |

Weight |

Price/ft. |

|

2 x 2 x 1/4" |

20'-0" |

64# |

$6.57 |

|

2-1/2 x 2-1/2 x 1/4" |

20'-0" |

84# |

$8.20 |

|

3 x 3 x 1/4" |

20'-0" |

98# |

$9.90 |

|

|

|

|

|

THE SOLUTION FOR TRUE LINEAR MOVEMENT |

|

|

|

|

|

Monorails

can be readily adapted for more

sophisticated applications by the addition of extra

tracks, curves, switches, and interlocks (transfers)

that can be easily integrated into a total system. The

pre-engineered modular designs offer the ultimate in

flexibility, in layout, and in design for your manufacturing

facility. |

|

|

|

|

System

priced upon request. |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

| PRICING

- MONORAIL CURVE |

|

|

|

|

|

|

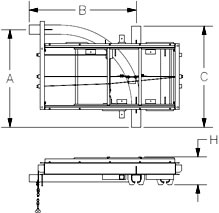

The

monorail curve is a section of track that

is rolled to provide a 90° curve. The curved

sections have a straight section which projects

beyond the curve. The curve needs to be

supported with three hangers, one in the

center, one at one end just outside the splice

joint, and one at the other end just inside the

splice joint. |

|

| CAP. (lbs.) |

250 |

500 |

1000 |

2000 |

| PRICE |

|

|

|

|

| PART NO. |

curve kit |

curve kit |

curve kit |

curve kit |

| RADIUS |

23-5/8" |

23-5/8" |

31-3/8" |

41" |

| X |

31-5/8" |

31-5/8" |

45" |

51" |

| WEIGHT |

17# |

27# |

53# |

73# |

|

|

|

|

|

|

|

|

|

|

|

|

|

Curve

is painted blue. Hangers (3 required) and track

splice joints are not included. 4 hangers required for

2000#. 4000# capacities are not available. Each hanger

must be braced to prevent movement "S" curve layouts

may require custom trolleys. Consult us for festooning

requirements. |

|

|

|

|

|

|

|

|

|

|

|

Greater

pull forces may be required. 100:1 productivity

ratio does not apply. |

|

|

|

|

PART

NUMBER: CURVE.KIT_____(fill in capacity) |

|

|

|

|

|

|

|

|

|

INTERLOCKS

(TRANSFERS) |

|

SWITCHES |

|

|

|

Interlocks

are used to transfer materials from the

working area of the bridge crane to storage monorails,

and vice versa. Request the Interlocks (Transfers) flyer

for additional information.

Priced upon request. |

Limited

sizes of switches can be provided. Please

contact us for additional information. |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

| PRICING

- SWITCHES |

|

|

|

|

|

|

|

|

PART

NUMBER: SWITCH.KIT Track series - Switch direction

(R)ight (L)eft - Electrified (Y)es or (N)o. |

|

|

|

|

|

|

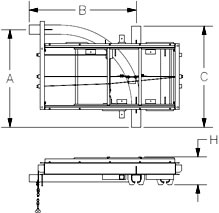

| CAP. (lbs.) |

250 |

500 |

1000 |

1000 |

2000 |

2000 |

| |

L / R |

L / R |

L |

R |

L |

R |

PRICE |

|

|

|

|

|

|

| PART NO. |

switch kit |

switch kit |

switch kit |

switch kit |

switch kit |

switch kit |

| A |

30-5/16" |

32-9/16" |

40-1/2" |

40-1/2" |

50-1/4" |

50-1/4" |

| B |

27-9/16" |

27-9/16" |

44-1/2" |

41-1/2" |

48-3/4" |

48-3/4" |

| C |

22-3/16" |

28-15/16" |

42" |

44-1/2" |

48-15/16" |

48-15/16" |

| H |

1-1/16" |

1-15/16" |

11-1/2" |

11-1/2" |

12" |

12" |

| WEIGHT |

29# |

33# |

294# |

294# |

359# |

359# |

|

Drawing

is only a representation.

Arrangements will vary per

application. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Available

in right or left hand (shown above) versions. 4 bar conductor

(not included) available for 1000# & 2000# switches only. Four (4)

hangers (not included). 4000# capacities are not available. |

Greater

pull forces may be required.

100:1 productivity ratio does not apply. |

|

| PRICING

- HANGERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hanger

assembly is painted blue. Includes beam clip and

hardware when threaded rod is provided. Fits flange

widths of 1" to 3", 3-1/4" to 5-1/4", 5-1/2" to

7-1/2",

and 8" to 10" and flange thickness up to 1/2" max.

for 250-500 lb. and 3/4" max. for 1000-4000 lb.

Please consult us for flanges not listed above. Sway

bracing is required except for flush mount applications. |

|

For

sloped ceiling consult us. |

|

|

*Hanger

drops greater than 6' we recommend rigid

hanger drops (by other). |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

STANDARD

HANGER ASSEMBLY

For

PLAIN STEEL track series 250# - 2000# |

|

|

|

|

|

|

|

|

|

|

| |

Capacity (lbs.) |

250 |

500 |

1000 |

2000 |

| No Rod |

Price (each) |

|

|

|

|

| H (minimum) |

8" |

8-7/8" |

10-1/8" |

10-5/8" |

| Weight |

16# |

18# |

24# |

27# |

| 20" Rod |

Price (each) |

|

|

|

|

| Weight |

18# |

20# |

26# |

29# |

| 72" Rod |

Price (each) |

|

|

|

|

| Weight |

21# |

23# |

29# |

32# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rods

are 5/8" in diameter. B7 Alloy - all thread. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STANDARD

HANGER ASSEMBLY

For

TRUSSED STEEL track series 250# - 2000# |

|

|

|

|

|

|

| |

Capacity (lbs.) |

250 |

500 |

1000 |

2000 |

| No Rod |

Price (each) |

|

|

|

|

| H (minimum) |

6-1/4" |

6-1/4" |

7" |

7" |

| Weight |

17# |

18# |

24# |

25# |

| 20" Rod |

Price (each) |

|

|

|

|

| Weight |

18# |

20# |

26# |

29# |

| 72" Rod |

Price (each) |

|

|

|

|

| Weight |

21# |

22# |

28# |

31# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rods

are 5/8" in diameter. B7 Alloy - all thread. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STANDARD

HANGER ASSEMBLY

For

PLAIN STEEL track series 4000# |

|

|

|

| |

Capacity (lbs.) |

4000 |

| No Rod |

Price (each) |

|

| H (minimum) |

14-1/2" |

| Weight |

56# |

| 20" Rod |

Price (each) |

|

| Weight |

58# |

| 72" Rod |

Price (each) |

|

| Weight |

61# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rods

are 3/4" in diameter. B7 Alloy - all thread. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

|

|

|

|

|

| |

Capacity (lbs.) |

4000 |

| No Rod |

Price (each) |

|

| H (minimum) |

11-1/2" |

| Weight |

56# |

| 20" Rod |

Price (each) |

|

| Weight |

58# |

| 72" Rod |

Price (each) |

|

| Weight |

61# |

|

|

STANDARD

HANGER ASSEMBLY

For

TRUSSED STEEL track series 4000# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rods

are 3/4" in diameter. B7 Alloy - all thread. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STANDARD

HANGER ASSEMBLY

For

ALUMINUM track series 250# - 2000# |

|

| |

Capacity (lbs.) |

250 |

500 |

1000 |

2000 |

| No Rod |

Price (each) |

|

|

|

|

| H (minimum) |

6-1/4" |

6-1/4" |

7" |

7" |

| Weight |

17# |

18# |

24# |

25# |

| 20" Rod |

Price (each) |

|

|

|

|

| Weight |

18# |

20# |

26# |

29# |

| 72" Rod |

Price (each) |

|

|

|

|

| Weight |

21# |

22# |

28# |

31# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

| PRICING

- TOUCH-UP PAINT |

|

|

|

|

|

|

|

| MODEL NO. |

COLOR |

PRICE |

| SP.12.OZ YEL |

YELLOW |

|

| YEL.GALLON |

YELLOW |

|

| SP.12.OZ BLU |

BLUE |

|

| BLUE.GALLON |

BLUE |

|

|

|

|

|

|

Available as

Quick Ship. |

|

|

|

|

|

|

|

|

Price

per spray can/gallon. There is an additional hazardous material

handling charge by UPS per box for paint. Can ship UPS Air except

to Canada (use FedEx). |

|

|

|

|

|

| PRICING

- TRACDOM |

|

|

|

Cover

for ends of rail sections

for steel bridges and runways

(yellow). |

|

| CAP. (lbs.) |

250 |

500 |

1000 |

2000 |

4000 |

| PRICE |

|

|

|

|

|

| YELLOW |

0215.Y |

0515.Y |

S1015.Y |

S2015.Y |

S2015.Y |

| WEIGHT |

1# |

1# |

1# |

1# |

1# |

|

|

|

| Available

as Quick Ship. |

|

|

|

|

Monorails-Enclosed Track

Design, Enclosed Track, Trolley, Festoon, Monorails, Overhead Conveyors,

and Monorail from your

source for material handling equipment. |

Back

to Product Category |

|

|