|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back

to Product Category

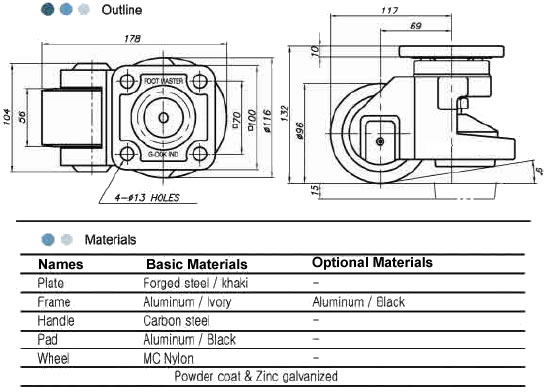

GD-150F

LEVELING PLATE CASTERS |

|

|

|

|

|

|

|

|

|

|

The

GD, GDN, and GDR Series of leveling casters are a solution to the age old

problem of flexible movement

combined with the ability of securely setting and braking a caster in a

specific location.The leveling foot, once set

in place, provides for stable, anti-vibrational placement. Our leveling

casters can easily move up to 6,600 Lbs

over four casters. Greater weight requirements may require the use of more

casters. Our casters are being used

on work stations medical, computer, communication, printing, woodworking,

automation and assembly equipment.

They are typically found in all manufacturing environments, including clean

room and laboratory facilities. |

|

|

|

|

|

|

|

|

|

|

|

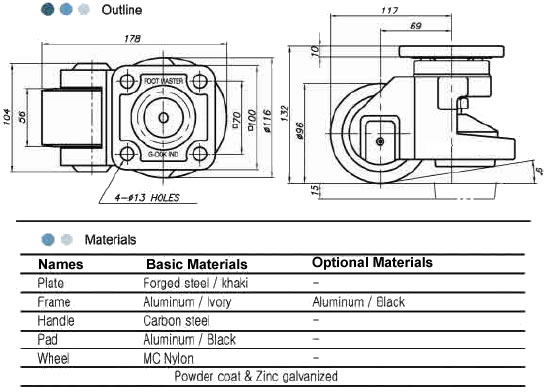

SPECIFICATIONS |

|

Load

Capacity (per caster): 3,300 lbs (1,500 kg)

Recommended Load (4 casters): 6,600 lbs. (3,000 kg)

Temperature Range: +14 ~ +194° F (-10 ~ +90° C)

Weight: 7.7 lbs. (3.5 kg)

Top Plate (1): 3 15/16" x 3 15/16"

(2 3/4" x 2 3/4")

Frame Material (2): Aluminum Die Cast

Handle (3): Carbon Steel

Leveling Pad Material (4): Aluminum

Wheel Material (5): MC Nylon

Surface Treatment: Powder Coated & Zinc Galvanized |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

| Model No. |

Top Plate (bolt hole

pattern) |

Load |

O.A.H. |

Weight |

Price (each) |

| GD-150F |

3.15/16 x 3.15/16"

(2.3/4 x 2.3/4") |

3,300 lbs. |

5 3/16" |

7.7 lbs. |

$146.00 |

|

|

| Understand

Leveling Casters... |

|

|

|

|

|

Moving a piece

of equipment into a desired location, applying

a wheel braking mechanism, and setting the unit into an exact

position; is easier said than done in many caster applications.

Our leveling casters offer a simple solution. |

|

|

|

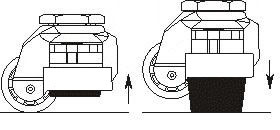

After installation

of the appropriate number of leveling casters,

with either standard top plates or threaded stems, the equipment

is easily pushed into position. Once positioned in the exact spot

of operation, the anti-vibration foot/pad is lowered, the caster

wheel is lifted off the ground, making the equipment completely

stationary. This pad allows for minor adjustments in leveling

requirements. When your equipment needs to be moved out

of the way; just raise the anti-vibrational foot/pad and push it

easily to a new location. |

|

|

|

|

|

|

|

| Three

types of handles |

Leveling

casters utilize three devices to raise and lower anti-vibration foot/pad. |

|

|

|

|

|

|

|

|

Manual

Handle |

Nut |

Ratchet |

|

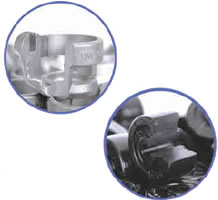

(4)

All production processes are kept in house to maintain higher quality, which

is managed

under ISO 9001. |

|

Unlike

most of competitors who had phased out in-house production. G-dok deeps

the in-house production with

craftmanship. It has always been our philosophy that we cannot get the best

quality if we do not do it ourselves,

and that quality is the only thing that endures. |

|

|

|

|

|

(5)

Ratchet system |

|

|

|

|

Ratchet

leveling casters are patented by G-dok. |

|

|

|

|

For

easier use, the self-contained ratcheting device is offered.

This device is protected by the patent law, so no competitor

can imitate this product. |

|

|

|

|

(6) RoHS |

100%

of all components found in the leveling

casters are manufactured to comply with world

wide RoHS requirements. |

|

|

|

|

|

|

| (8)

Side and Back Access |

|

| Convenient

multiple designs |

The

GD series is standard with a larger radial opening, which allows for easier

adjustment in a multitude of

applications. The GDN series offers a rear access opening for adjustment

of the stabilizing pad. |

|

|

|

Leveling Stem Casters, Plate

Casters, Retractable Caster, Adjustable Casters, Lifting Caster, Ratchet

Caster, Leveling Casters, Swivel Caster, Nylon Wheels, Leveling Pads,

and Locking Casters from your source for material handling equipment. |

Back

to Product Category |

|

|