|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

FS350

Insert Mounted

1-1/2 Ton Capacity |

FS350S

- SLEEVE MOUNTED (Add Sleeve - See below insert

mounted) |

|

| FS350 (Insert Mounted) |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

PRICING - (Dimension charts

are listed below pricing) - (Accessory Pricing

is listed below the dimension charts) |

| HUB |

SPAN |

8' |

9' |

10' |

11' |

12' |

13' |

14' |

15' |

16' |

17' |

18' |

19' |

20' |

| 8' |

Model (E-W) |

12-W10 |

12-W10 |

14-W10 |

14-W10 |

14-W10 |

14-W12 |

14-W12 |

14-W16 |

16-W16 |

16-W16 |

16-W18 |

16-W18 |

16-W18 |

| Weight (lbs) |

1032# |

1057# |

1292# |

1312# |

1342# |

1457# |

1487# |

1724# |

2176# |

2218# |

2372# |

2633# |

2683# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 9' |

Model (E-W) |

12-W10 |

12-W10 |

14-W10 |

14-W10 |

14-W10 |

14-W12 |

16-W12 |

16-W16 |

16-W16 |

16-W16 |

16-W18 |

16-W18 |

16-W18 |

| Weight (lbs) |

1067# |

1092# |

1337# |

1362# |

1392# |

1502# |

1962# |

2189# |

2236# |

2278# |

2437# |

2703# |

2753# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 10' |

Model (E-W) |

12-W10 |

12-W10 |

14-W10 |

14-W10 |

16-W10 |

16-W12 |

16-W12 |

16-W16 |

16-W16 |

16-W16 |

16-W18 |

16-W18 |

16-W18 |

| Weight (lbs) |

1092# |

1122# |

1382# |

1402# |

1867# |

1977# |

2017# |

2249# |

2296# |

2238# |

2492# |

2768# |

2818# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 11' |

Model (E-W) |

12-W10 |

12-W10 |

14-W10 |

14-W10 |

16-W10 |

16-W12 |

16-W12 |

16-W16 |

16-W16 |

16-W16 |

16-W18 |

16-W18 |

18-W18 |

| Weight (lbs) |

1127# |

1152# |

1422# |

1447# |

1927# |

2042# |

2077# |

2309# |

2356# |

2398# |

2552# |

2838# |

3438# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 12' |

Model (E-W) |

12-W10 |

12-W10 |

14-W10 |

14-W10 |

16-W10 |

16-W12 |

16-W12 |

16-W16 |

16-W16 |

16-W16 |

18-W18 |

18-W18 |

18-W18 |

| Weight (lbs) |

1162# |

1187# |

1467# |

1487# |

1987# |

2102# |

2142# |

2374# |

2416# |

2347# |

2857# |

3488# |

3538# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 13' |

Model (E-W) |

12-W10 |

12-W10 |

14-W10 |

14-W10 |

16-W10 |

16-W12 |

16-W12 |

16-W16 |

16-W16 |

18-W16 |

18-W18 |

18-W18 |

20-W18 |

| Weight (lbs) |

1192# |

1217# |

1512# |

1532# |

2047# |

2157# |

2187# |

2429# |

2476# |

2778# |

2922# |

3563# |

4138# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 14' |

Model (E-W) |

12-W10 |

12-W10 |

14-W10 |

16-W10 |

16-W10 |

16-W12 |

18-W12 |

18-W16 |

18-W16 |

18-W16 |

18-W18 |

18-W18 |

20-W18 |

| Weight (lbs) |

1222# |

1252# |

1562# |

2077# |

2107# |

2222# |

2532# |

2789# |

2831# |

2868# |

3642# |

3683# |

4253# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 15' |

Model (E-W) |

12-W10 |

12-W10 |

14-W10 |

16-W10 |

18-W10 |

18-W12 |

18-W12 |

18-W16 |

18-W16 |

18-W16 |

18-W18 |

18-W18 |

20-W18 |

| Weight (lbs) |

1252# |

1282# |

1602# |

2137# |

2437# |

2547# |

2577# |

2854# |

2896# |

2938# |

3742# |

4328# |

4373# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 16' |

Model (E-W) |

12-W10 |

14-W10 |

14-W10 |

16-W10 |

18-W10 |

18-W12 |

18-W12 |

18-W16 |

18-W16 |

18-W16 |

18-W18 |

20-W18 |

20-W18 |

| Weight (lbs) |

1287# |

1617# |

1647# |

2197# |

2502# |

2632# |

2662# |

2924# |

2961# |

3003# |

3842# |

4443# |

4493# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 17' |

Model (E-W) |

12-W10 |

14-W10 |

14-W10 |

16-W10 |

18-W10 |

18-W12 |

18-W12 |

18-W16 |

20-W16 |

20-W16 |

20-W18 |

20-W18 |

24-W18 |

| Weight (lbs) |

1317# |

1682# |

1692# |

2257# |

2567# |

2702# |

2727# |

2989# |

3366# |

3788# |

3942# |

4563# |

4618# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 18' |

Model (E-W) |

12-W10 |

14-W10 |

16-W10 |

16-W10 |

18-W10 |

18-W12 |

18-W12 |

20-W16 |

20-W16 |

20-W16 |

20-W18 |

20-W18 |

24-W18 |

| Weight (lbs) |

1347# |

1702# |

2297# |

2317# |

2632# |

2752# |

2787# |

3799# |

3836# |

3888# |

4632# |

4683# |

4728# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 19' |

Model (E-W) |

12-W10 |

14-W10 |

16-W10 |

16-W10 |

20-W10 |

20-W12 |

20-W12 |

20-W16 |

20-W16 |

20-W16 |

20-W18 |

24-W18 |

24-W18 |

| Weight (lbs) |

1382# |

1752# |

2357# |

2382# |

3502# |

3617# |

3647# |

3894# |

3936# |

3988# |

4752# |

4803# |

4848# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20' |

Model (E-W) |

12-W10 |

14-W10 |

16-W10 |

16-W10 |

20-W10 |

20-W12 |

20-W12 |

20-W16 |

20-W16 |

20-W16 |

20-W18 |

24-W18 |

24-W18 |

| Weight (lbs) |

1407# |

1792# |

2417# |

2437# |

3602# |

3717# |

3747# |

3994# |

4036# |

4088# |

4872# |

4918# |

4968# |

| Price |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Foundation Size |

6'0"x6'0"x4'0" |

7'0"

x7'0"x4'0" |

8'0" x8'0"x4'0" |

|

Model

Number Explanation

Example: 1/4 Ton FS350-8-6; 1/4 Ton = 500 pound capacity, FS350 =insert

mount style, 8 = mast diameter in inches (E),

6 = boom depth in inches (W). Use "E" dimension to determine base

plate and anchor bolt dimensions. |

| Jib

crane foundation requirements are based on soil pressure of 2500#/sq. ft.

and 3000 psi reinforced concrete. |

| AISC

specifications adhered to. If additional specifications are to be met, consult

us. |

|

|

|

Chart

1B. Boom Data |

|

|

|

|

|

| STANDARD

BOOM DATA |

Boom

Height (W) |

Beam Size |

Flange

Width (in) |

| 6" |

W6@12#/ft. |

4" |

| 8.125" |

W8@18#/ft. |

5-1/4" |

| 10.33" |

W10@26#/ft. |

5-3/4" |

| 12.5" |

W12@35#/ft. |

6-1/2" |

| 16.125" |

W16@45#/ft. |

7" |

| 18" |

W18@50#/ft. |

7-1/2" |

| 21" |

W21@62#/ft. |

8-1/4" |

| 24.125" |

W24@84#/ft. |

9" |

|

|

|

|

|

|

| FS350

INSERT MOUNTED |

|

|

|

|

|

2.7 Pour the first footing, according to the footing

dimensions in diagrams 2C and 2D, and charts

2C and 2D, with the anchor bolts (J-bolts) (by others)

in place. |

|

Chart

2C. Crane Dimensions |

|

PIPE

SIZE |

DIMENSIONS |

ANCHOR BOLT

PATTERN |

| E |

J |

K |

H1 |

H2 |

D |

P |

Q |

| 8 |

10-3/8 |

10 |

47 |

4 |

13/16 |

11 |

8 |

| 12 |

12-7/8 |

12-1/2 |

71-3/4 |

6 |

13/16 |

15 |

12 |

| 14 |

15-3/8 |

15 |

72 |

8 |

13/16 |

17 |

14 |

| 16 |

17-3/8 |

17 |

72 |

8 |

13/16 |

19 |

16 |

| 18 |

17-3/8 |

17 |

72 |

9 |

13/16 |

21 |

18 |

| 20 |

17-7/8 |

17-1/2 |

72 |

10 |

13/16 |

23 |

20 |

| 24 |

22-7/8 |

22-1/2 |

77 |

12 |

13/16 |

27 |

24 |

| 30 |

25-3/8 |

25 |

84 |

12 |

13/16 |

33 |

30 |

|

|

|

|

|

| NOTE: |

|

|

Jib

crane foundation requirements are based on a

soil pressure of 2500 lbs. per square foot. Concrete

recommended for jib crane foundation is 3000 lbs.

per square inch of compressive force. |

|

|

|

|

|

| NOTE: |

|

|

|

Foundation/concrete

must cure seven (7) days

prior to mast installation. Foundation/concrete must

cure 28 days prior to using crane to full capacity. |

|

|

|

|

|

|

|

2.8 Once the concrete has cured, set the mast into

place. |

|

Chart 2D. Foundation

Depth |

|

| STANDARD

FOOTING REQUIREMENTS |

| Capacity Tons |

Span (ft.) |

Width (ft.) M |

Depth (ft.) L |

| 1/4 |

8-13 |

4 |

3 |

| 1/4 |

14-20 |

4 |

4 |

| 1/2 |

8-12 |

4 |

4 |

| 1/2 |

13-20 |

5 |

4 |

| 1 |

8-10 |

5 |

4 |

| 1 |

11-15 |

6 |

4 |

| 1 |

16-20 |

7 |

4 |

| 1-1/2 |

8-12 |

6 |

4 |

| 1-1/2 |

13-15 |

7 |

4 |

| 1-1/2 |

16-20 |

8 |

4 |

| 2 |

8-11 |

6 |

4 |

| 2 |

12-15 |

7 |

4 |

| 2 |

16-20 |

8 |

4 |

| 3 |

8-16 |

8 |

4 |

| 3 |

17-20 |

9 |

4 |

| 4 |

8-13 |

8 |

4 |

| 4 |

14-20 |

10 |

4 |

| 5 |

8-14 |

9 |

4 |

| 5 |

15-18 |

10 |

4 |

| 5 |

19-20 |

10 |

5 |

|

|

|

2.9 Plumb mast following the plumbing procedure in

Step 3. |

|

|

|

| 2.10 Once mast is plumb, tighten anchor bolts per manufacturer’s specifications. |

|

|

|

2.11 Make the second pour according to the footing

dimensions in diagram 2C, and chart 2D. |

|

|

|

| 2.12 Proceed to Step 4, Head Installation. |

|

|

|

|

|

|

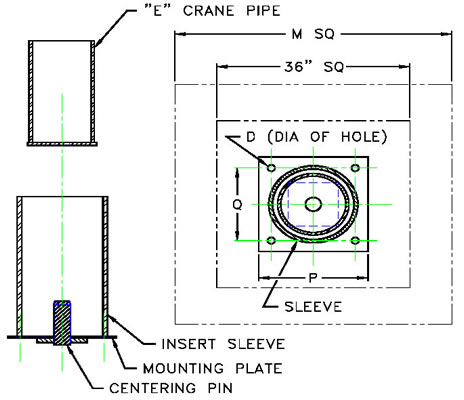

| FS350S - SLEEVE MOUNTED |

|

|

|

|

|

| Chart

2E. Stiffener Plate and Center Pin Cut-Out Requirements |

| Pipe Size (E) |

Footing Depth (L) |

Stiffener Plate Size

(in. sq.) |

Center Pin Depth

(in.) |

| 8 |

36 |

6 |

15/16 |

| 8 |

48 |

6 |

15/16 |

| 12 |

36 |

6 |

15/16 |

| 12 |

48 |

6 |

15/16 |

| 14 |

48 |

6 |

15/16 |

| 16 |

48 |

6 |

15/16 |

| 18 |

48 |

6 |

15/16 |

| 20 |

48 |

6 |

15/16 |

| 24 |

48 |

8 |

1-3/16 |

| 30 |

48 |

8 |

1-3/16 |

| 30 |

60 |

8 |

1-3/16 |

|

|

|

|

|

|

Chart

1B. Boom Data |

|

|

|

|

|

| STANDARD

BOOM DATA |

Boom

Height (W) |

Beam Size |

Flange

Width (in) |

| 6" |

W6@12#/ft. |

4" |

| 8.125" |

W8@18#/ft. |

5-1/4" |

| 10.33" |

W10@26#/ft. |

5-3/4" |

| 12.5" |

W12@35#/ft. |

6-1/2" |

| 16.125" |

W16@45#/ft. |

7" |

| 18" |

W18@50#/ft. |

7-1/2" |

| 21" |

W21@62#/ft. |

8-1/4" |

| 24.125" |

W24@84#/ft. |

9" |

|

|

|

|

|

|

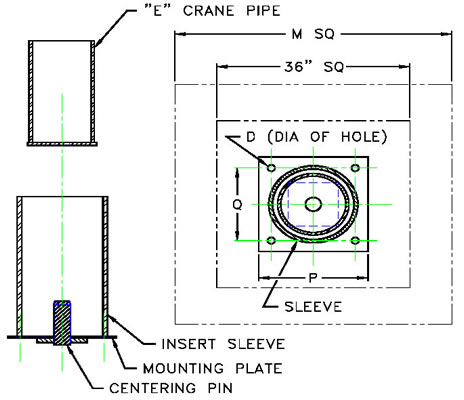

| FS350S

SLEEVE INSERT MOUNTED |

|

|

|

|

|

2.13 Pour the first footing, according to the footing

dimensions in diagrams 2E and 2F, and charts 2F

and 2G, with the anchor bolts (J-bolts) (by others) in

place. See chart 2E to calculate stiffener plate and

center pin cut-out requirements. |

|

Chart

2F. Crane Dimensions |

|

PIPE

SIZE |

DIMENSIONS |

ANCHOR BOLT

PATTERN |

| E |

J |

K |

H1 |

H2 |

D |

P |

Q |

| 8 |

10-3/8 |

10 |

47 |

4 |

1 |

13 |

10 |

| 12 |

12-7/8 |

12-1/2 |

71-3/4 |

6 |

1 |

17 |

14 |

| 14 |

15-3/8 |

15 |

72 |

8 |

1 |

19 |

16 |

| 16 |

17-3/8 |

17 |

72 |

8 |

1 |

21 |

18 |

| 18 |

17-3/8 |

17 |

72 |

9 |

1 |

23 |

20 |

| 20 |

17-7/8 |

17-1/2 |

72 |

10 |

1 |

25 |

22 |

| 24 |

22-7/8 |

22-1/2 |

77 |

12 |

1 |

29 |

26 |

| 30 |

25-3/8 |

25 |

84 |

12 |

1 |

35 |

32 |

|

|

|

|

|

| NOTE: |

|

|

Jib

crane foundation requirements are based on a

soil pressure of 2500 lbs. per square foot. Concrete

recommended for jib crane foundation is 3000 lbs.

per square inch of compressive force. |

|

|

|

|

|

| NOTE: |

|

|

|

Foundation/concrete

must cure seven (7) days

prior to mast installation. Foundation/concrete must

cure 28 days prior to using crane to full capacity. |

|

|

|

|

|

|

|

2.14 Once the concrete has set, set the sleeve in

place (confirm sleeve size prior to setting) and tighten

the anchor bolts, making sure the sleeve is plumb. |

|

Chart 2G. Foundation

Depth |

|

| STANDARD

FOOTING REQUIREMENTS |

| Capacity Tons |

Span (ft.) |

Width (ft.) M |

Depth (ft.) L |

| 1/4 |

8-13 |

4 |

3 |

| 1/4 |

14-20 |

4 |

4 |

| 1/2 |

8-12 |

4 |

4 |

| 1/2 |

13-20 |

5 |

4 |

| 1 |

8-10 |

5 |

4 |

| 1 |

11-15 |

6 |

4 |

| 1 |

16-20 |

7 |

4 |

| 1-1/2 |

8-12 |

6 |

4 |

| 1-1/2 |

13-15 |

7 |

4 |

| 1-1/2 |

16-20 |

8 |

4 |

| 2 |

8-11 |

6 |

4 |

| 2 |

12-15 |

7 |

4 |

| 2 |

16-20 |

8 |

4 |

| 3 |

8-16 |

8 |

4 |

| 3 |

17-20 |

9 |

4 |

| 4 |

8-13 |

8 |

4 |

| 4 |

14-20 |

10 |

4 |

| 5 |

8-14 |

9 |

4 |

| 5 |

15-18 |

10 |

4 |

| 5 |

19-20 |

10 |

5 |

|

|

|

2.15 Make the second pour according to the footing

dimensions in diagram 2F, and chart 2G. |

|

|

|

2.16 When the second pour has cured, insert the

mast inside the sleeve. Ensure that the center

pin is fully inserted in the centering hole in the

mast. |

|

|

|

2.17 Using steel wedges (included) every 60º, plumb

mast following the plumbing procedure in Step 3. |

|

|

|

2.18 Once the mast is plumb, weld the steel wedges

to the mast and sleeve to prevent any shifting of

the mast. |

|

|

|

WARNING |

|

All

welds must meet American Welding Society

(AWS) specification D1.1 using E70xx electrodes. |

|

|

|

|

| FS350S

- SLEEVE ASSEMBLY |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

ANCHOR

BOLT PATTERN |

| PART NUMBER |

E (MAST DIA.) |

D (IN) |

P (IN) |

Q (IN) |

L |

WT. |

SLEEVE PRICE |

| 55835A |

8 |

1 |

13 |

10 |

3' |

105# |

|

| 55836A |

8 |

1 |

13 |

10 |

4' |

133# |

|

| 55837A |

12 |

1 |

17 |

14 |

4'-1/8" |

259# |

|

| 55838A |

14 |

1 |

19 |

16 |

4' |

309# |

|

| 55839A |

16 |

1 |

21 |

18 |

4' |

352# |

|

| 55840A |

18 |

1 |

23 |

20 |

4' |

517# |

|

| 55841A |

20 |

1 |

25 |

22 |

4' |

615# |

|

| 55842A |

24 |

1 |

29 |

26 |

4' |

674# |

|

| 55843A |

30 |

1 |

35 |

32 |

4' |

984# |

|

| 55844A |

30 |

1 |

35 |

32 |

5' |

1152# |

|

|

|

ACCESSORIES |

|

Included

in the base price of all jib cranes: Jib End Stops, Installation & Maintenance

Manual (2), Touch-Up Paint

(1 spray can). |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

| Description |

Approx.

Ship Wt. |

Price |

| Free Standing Series Manual Rotation Stops. Three pieces

shipped loose for field welding. |

1 |

|

Tagline Assemblies. (if desired without collector).

Includes two trolley stops with tagline angle,

tagline cable, 2 cable clamps, 2 eye bolts, and 5 "S" hooks.

Electrical wire is not included (See "Flat

and Round Cable") |

25 |

|

| End Stop Kits. Includes two trolley stops with hardware.

Tagline is not included. |

|

| a. for beam sizes S6, W8 and S10 |

2 |

|

| b. for beam sizes S12, W16, W18, W21 and W24 |

2 |

|

Free Standing Crane Bottom Entry Collector. Includes

- 4 ring collector, collector cover, 4 pieces of

#12 wire through mast, 1 junction box at base of mast, tagline assembly,

and 1 collector to adapter pin

if required. Electrical wire from the collector to the hoist is not

included. (See "Flat and Round Cable"). |

29 |

|

Free Standing Crane Top Entry Collector. Includes 4

ring collector and tagline assembly. Electrical wire

from the collector to the hoist is not included. (See "Flat and

Round Cable"). Adds 10-1/2" to OAH. |

35 |

|

FS Series 360 Rotation Air Swivel Bottom Entry and internally

piped (specify 1/2" or 3/4" diameter airline).

3/4" airline will not fit 8 or 12 mast size. Includes: tagline

assy., male NPT thread at bottom of mast assembly

and at top of head assembly. Air hose from swivel to the hoist not

included. Add 9-1/8" to OAH. |

48 |

|

FS Series 360 Rotation Air Swivel Top Entry (specify

1/2" or 3/4" diameter airline). Includes: tagline

assembly, male NPT threads. Air hose from swivel to the hois not included.

Adds 9-1/8" to OAH. |

25 |

|

| Multi-position Lock Device - For FS, WB, & WC Series.

Indoor Applications only (no wind load conditions). |

up to

450 |

|

| Single-position Lock Device - For Free Standing Crane.

Indoor Applications only (no wind load conditions). |

up to

250 |

|

Retrofit I Universal Motorized Kit. - 1/4 ton - 2 ton,

20' span max. Indoor use only. Includes: AC Mainline

Contactor (optional) |

|

| Retrofit II Universal Motorized Kit. - 3 ton - 5 ton,

20' span max. Indoor use only. Includes: AC Mainline Contactor (optional) |

|

| Flat and Round Wire - 4 conductor #14 |

.1/ft. |

|

| Flat and Wire Cord Grip Connectors - for 4 conductor

#14 flat wires |

3 |

|

| Air Hose |

| a. 3/8" ID |

.1/ft. |

|

| b. 1/2" ID |

.1/ft. |

|

| Wire Rope Trolley - (specify for flat or round wire) |

1 |

|

| Fusible Disconnect Switches. Includes mounting bracket

to attach to mast |

| a. Nema 1 - Indoor Use Only |

10 |

|

| b. Nema 12 - Indoor Use Only |

10 |

|

| c. Nema 3R - Outdoor Use Only |

10 |

|

| d. Nema 4 - Indoor or Outdoor Use |

10 |

|

| e. Nema 4X - Indoor or Outdoor Use |

10 |

|

|

|

|

|

| Please

contact us for pricing on the following options: |

|

a. Special

Paint |

|

|

b. Sandblasting |

|

|

c. Galvanizing |

|

|

d. 2"

diameter |

|

|

e. Minimum

total rod charge |

|

|

Insert Mounted Jib Cranes,

Sleeve Mounted Jib Cranes, Cranes, Articulating Jib Cranes, Gorbel Jib

Cranes, Jib Cranes,

Floor Mounted Jib Cranes, Gorbel Cranes, Hoist, and Jib Booms from your

source for material handling equipment. |

Back

to Product Category |

|

|