|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back

to Product Category

|

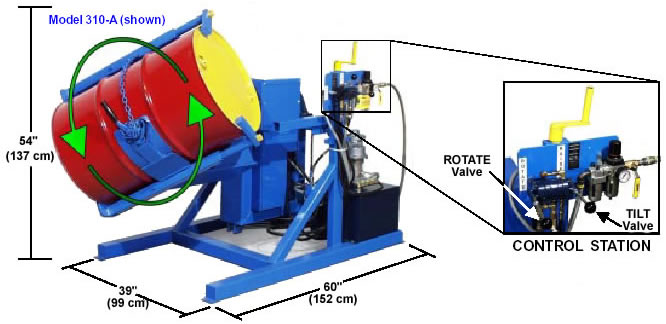

Load

upright drum at floor level |

|

Secure

your drum in holder |

|

Powered

lift and rotate |

|

|

|

|

|

|

|

|

|

|

|

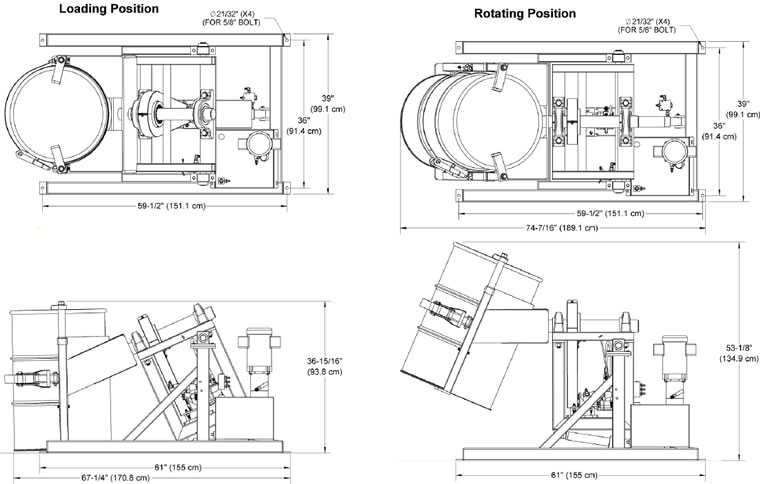

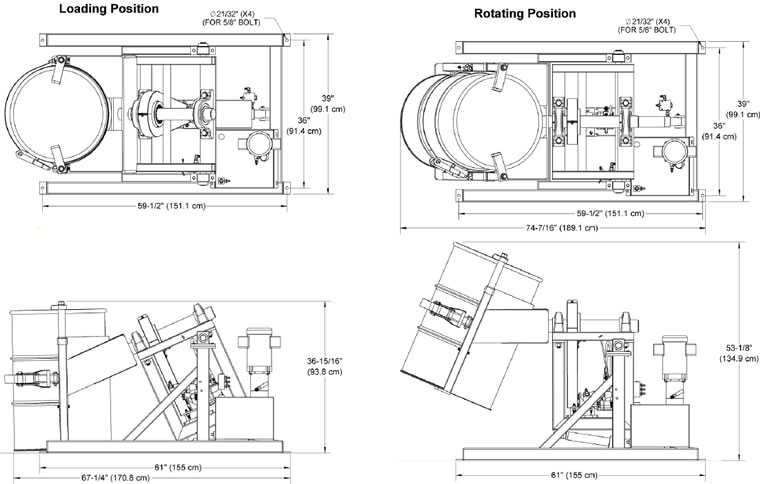

Load drum

into the rotator with the

drum holder in the lowered position,

the hinged ratchet plate and the top

clamps both open. The Model 152

Drum Truck is shown loading the

drum into the rotator. Can also load

with Model 81 Drum Spotter or

Model 92 Below-Hook Drum

Lifter (inset). |

|

Secure drum in the

rotator using the

cinch chain and ratchet, and

tightening the top clamps (inset). |

|

Turn the

motor on to activate the

hydraulics. Raise the drum to the top

position by raising the TILT control

valve. To begin rotating, raise the

ROTATE control valve. |

|

|

|

|

|

|

|

|

*

Half-full Capacity is an indication of the capacity for tilting an unbalanced,

bottom-heavy drum. A partially full drum with an unbalanced and shifting

load is harder to tilt than a full drum. |

|

|

CONTROL

PACKAGES (sold separately) |

|

|

|

|

|

|

|

|

Select

the appropriate Control Package for each model, and your power supply. Use

power controls to start and

stop drum rolling. The control mast can be positioned outside the Safety

Enclosure on either the left or right side,

or at the back of Drum Tumbler. |

|

|

|

|

|

|

|

|

| AC Control

Package (sold separately) NEMA 4/12 for NON-Hazardous Areas |

|

|

|

|

|

|

|

|

|

|

| Includes

Control Box with: |

|

|

|

|

|

|

|

|

|

|

|

•

Timer adjusts from a few seconds to 16 hours

• Start and Stop Buttons

• Red Emergency Stop Button

• Lockable Main Disconnect to shut off and lock

out power to the unit

• 24V DC Control Supply

• Wire terminals for external connection of safety

interlock switch |

|

|

|

|

|

|

Explosion

Proof AC Control Packages

NEMA 7/9 for Hazardous Areas

(sold separately) |

|

|

| Includes

Control Box with: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•

Start and Stop Buttons

• Wire terminals for external connection

of safety interlock switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Control

Package Information |

Control

Package No. |

Control

Package

For Model No. |

Min

Power

Supply |

Power

Supply |

Shipping

Weight |

CP-310-1-115* |

310-1 |

30

Amp |

1-Phase

115V 60Hz |

40

lbs |

CP-310-1-230* |

310-1 |

15

Amp |

1-Phase

230V 60Hz |

40

lbs |

CP-310-1-220-50 |

310-1-50 |

15

Amp |

1-Phase

220V 50Hz |

40

lbs |

CP-310-3-230* |

310-3 |

15

Amp |

3-Phase

230V 60Hz |

40

lbs |

CP-310-3-460* |

310-3 |

10

Amp |

3-Phase

460V 60Hz |

40

lbs |

CP-310-3-230-50 |

310-3-50 |

10

Amp |

3-Phase

230V 50Hz |

40

lbs |

CP-310-3-400-50 |

310-3-50 |

10

Amp |

3-Phase

400V 50Hz |

40

lbs |

CP-310-3-575 |

310-3-575 |

10

Amp |

3-Phase

575V 60Hz |

40

lbs |

CP-310-E1-115* |

310-E1,

Explosion-Proof |

30

Amp |

1-Phase

115V 60Hz |

70

lbs |

CP-310-E1-230* |

310-E1,

Explosion-Proof |

15

Amp |

1-Phase

230V 60Hz |

70

lbs |

CP-310-E1-220-50* |

310-E1-50,

Explosion-Proof |

15

Amp |

1-Phase

220V 50Hz |

70

lbs |

CP-310-E3-230* |

310-E3,

Explosion-Proof |

15

Amp |

3-Phase

230V 60Hz |

70

lbs |

CP-310-E3-230-50* |

310-E3-50,

Explosion-Proof |

15

Amp |

3-Phase

230V 50Hz |

70

lbs |

CP-310-E3-460* |

310-E3,

Explosion-Proof |

10

Amp |

3-Phase

460V 60Hz |

70

lbs |

CP-310-E3-400-50* |

310-E3-50,

Explosion-Proof |

10

Amp |

3-Phase

400V 50Hz |

70

lbs |

|

|

|

|

|

|

|

|

|

| Air

Controls are Included with Model 310-A |

|

|

| Air

Controls Include: |

|

|

•

Filter, Regulator and Lubricator (FRL)

• On / Off Valve |

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

Model

310 Prices |

| Note: Control Packages are sold separately. |

Model

No. |

RPM |

Motor

Style |

Motor

Information |

Weight

(lbs) |

Price |

Control

Packages |

HP |

Phase |

Motor

Voltage |

Amp

Draw |

Model

No. |

Price |

|

5-20 |

60

Hz TEFC |

2 |

1 |

115 |

23† |

950 |

$15,397 |

|

$2,785 |

208/230 |

12/11.5 |

|

$2,656 |

|

4-16 |

50

Hz TEFC |

2 |

1 |

220 |

9.7 |

950 |

$16,263 |

|

$2,785 |

|

5-20 |

60

Hz TEFC |

2 |

3 |

208/230 |

6.2/5.8 |

950 |

$15,269 |

|

$2,527 |

460 |

2.9 |

|

$2,393 |

|

4-16 |

50

Hz TEFC |

2 |

3 |

230 |

5.2 |

950 |

$15,561 |

|

$2,527 |

400 |

3 |

|

$2,504 |

|

5-20 |

60

Hz TEFC |

2 |

3 |

575 |

2.2 |

950 |

$15,257 |

|

$3,241 |

|

5-20 |

60

Hz Explosion

Proof ** |

2 |

1 |

115 |

23† |

1000 |

$17,527 |

|

$4,382 |

208/230 |

12/11.5 |

|

$4,820 |

|

4-16 |

50

Hz Explosion

Proof ** |

2 |

1 |

220 |

9.8 |

1000 |

$18,018 |

|

$5,031 |

208/230 |

5.5/5.2 |

|

$4,809 |

|

5-20 |

60

Hz Explosion

Proof ** |

2 |

3 |

460 |

2.6 |

1000 |

$17,328 |

|

$4,820 |

230 |

5.5 |

|

$5,031 |

|

4-16 |

50

Hz Explosion

Proof ** |

2 |

3 |

400 |

3.2 |

1000 |

$16,965 |

|

$5,616 |

|

5-20 |

AirMotor

*** |

- |

- |

- |

- |

950 |

$15,444 |

Air

Controls Included*** |

- |

|

*

ONLY NON-Explosion Proof AC Control Packages include a pre-wired control

box.

Explosion-proof Control Packages have no wiring from the NEMA 7/9

control box to the motor. Please consult an electrician to complete the

wiring in accordance to local code.

** Explosion-proof motors are rated for Class I Group D, and Class II Groups

F and G. |

***

Air powered model requires plant air at 50 to 60 PSI and flowing at a rate

of 60 SCFM.

Filter, Regulator, Lubricator and valve are included with drum Tumbler model

310-A.

† Requires 30 Amp circuit, and can have amp spikes higher than that. |

|

|

|

|

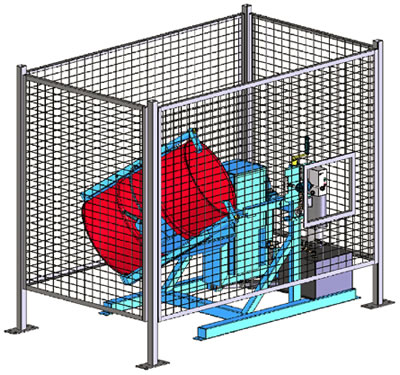

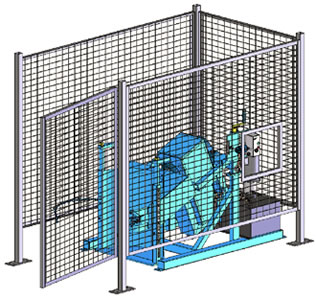

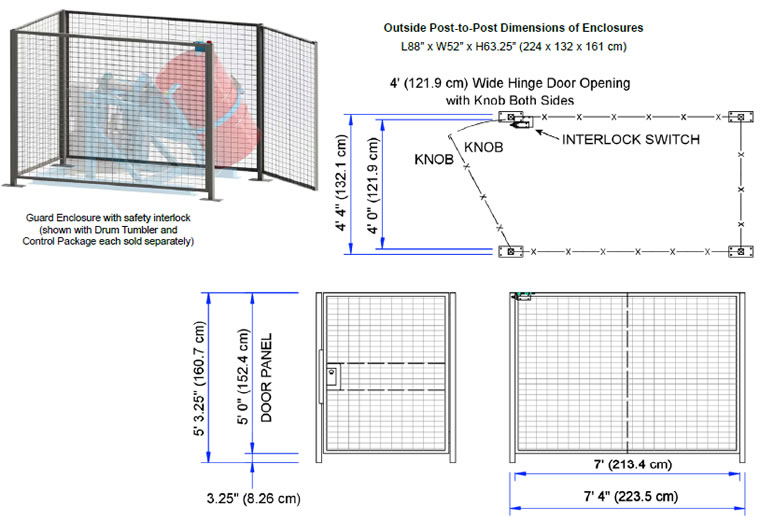

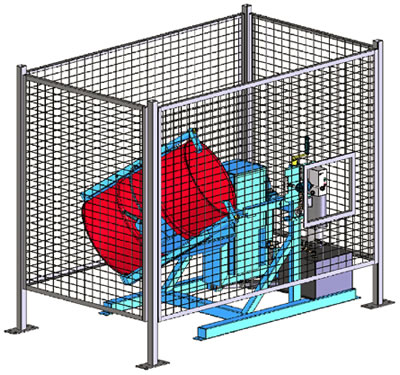

Enclosures

with Safety Interlock for Tilt-To-Load Drum Tumblers |

|

|

|

|

Help

You Comply with OSHA Requirements |

|

|

(Drum

Tumblers Sold Separately) |

|

|

|

Enclosures

for Tilt-To-Load Drum Rotators have

a safety interlock to automatically shut off the drum

roller when the gate is opened. Open the enclosure

gate, secure your upright drum on the base plate,

then close the gate to allow operation. An opening

in the side of the enclosure provides access to the

RAISE and ROTATE controls on the drum roller

with the drum safely enclosed. |

|

|

|

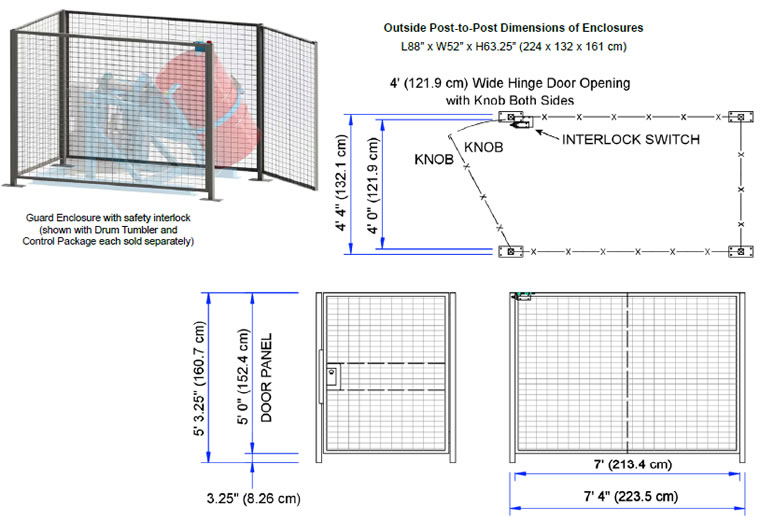

| Outside post-to-post

Dimensions: L88" x W52" x H74" |

|

|

|

Install

all Morse Drum Rotators in accordance with

OSHA requirements for enclosure and safety interlock,

etc. Drum roller automatically turns

off when

enclosure door is opened. |

|

|

|

For OSHA

compliance, see OSHA subpart

O.1910.212(a)(4) "Barrels, containers, and drums.

Revolving drums, barrels, and containers shall be

guarded by an enclosure which is interlocked with

the drive mechanism, so that the barrel, drum, or

container cannot revolve unless the guard enclosure

is in place." |

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

Rotator

Model 310 Prices |

Model

No. |

Fits

Model No. |

Gate

Switch |

Shipping

Dimensions |

Shipping

Weight |

Price |

|

310-1,

310-1-50 |

AC |

101"L

x 31"W x 66"H |

400

lbs |

$4,826 |

|

310-3,

310-3-50, 310-3-575 |

AC |

101"L

x 31"W x 66"H |

400

lbs |

$4,826 |

|

310-E1,

310-E1-50 |

AC

Exp. Proof |

101"L

x 31"W x 66"H |

400

lbs |

$5,312 |

|

310-E3,

310-E3-50, 310-E3-575 |

AC

Exp. Proof |

101"L

x 31"W x 66"H |

400

lbs |

$5,312 |

|

310-A |

Air

Switch |

101"L

x 31"W x 66"H |

400

lbs |

$5,376 |

|

| *Explosion Proof rated

for Class I Group D, and Class II Groups F and G |

|

Tilt-To-Load Drum Rotator,

Morse Model 310, Mix, Blend, Tumble, Drum Dumpers, Drum Rotators, Dumpers,

Barrel Dumpers,

Drum Handlers, Drum Handling, and Drum Lifting from your source for material

handling equipment. |

Back

to Product Category |

|

|