|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

TOP-OF-DOCK-LEVELERS

|

Hydraulic

Surface Mounted Dock Levelers

|

|

|

|

|

|

|

|

|

|

BENEFITS |

|

|

|

|

The

Top-Of-Dock is economical, allowing you The

Top-Of-Dock is economical, allowing you

to improve loading dock efficiency at a fraction

of the cost of pit-mounted dock levelers. Initial

cost is low. Maintenance is reduced to simple,

periodic lubrication and adjustment.

|

|

|

|

|

The

Top-Of-Dock is adaptable. A full 10" reach The

Top-Of-Dock is adaptable. A full 10" reach

above dock height is attainable. |

|

|

|

|

|

|

|

|

|

The

Top-Of-Dock is easy to install on virtually The

Top-Of-Dock is easy to install on virtually

any existing dock. No pit or other expensive

concrete work is required. It requires only 35"

back from dock edge.

|

|

|

|

|

|

The

Top-Of-Dock is easy to operate for one man The

Top-Of-Dock is easy to operate for one man

using one hand - whether you choose mechanical

or hydraulic operation. |

|

|

|

The

Top-Of-Dock is stout. Face plate and lip are The

Top-Of-Dock is stout. Face plate and lip are

high strength steel safety tread plate. Precision

bearings are used at load points. To safely

accommodate a wide range of trailer heights, full

18" high bumpers are standard equipment. These

bumpers are molded of first quality rubber and

secured to high strength 5/16" fully welded

bumper blocks.

|

|

|

|

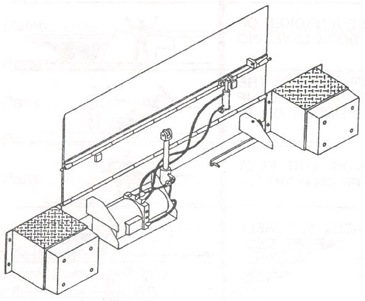

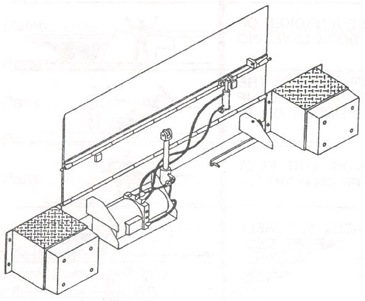

| HYDRAULIC

OPERATION |

|

|

Top-Of-Dock is offered in

your choice of a mechanically

or hydraulically operated model. With either model, you

can choose between 20,000 or 25,000 lb. capacity.

No matter which Top-Of-Dock you choose, you'll enjoy

years of smooth, dependable service and easy operation.

For hydraulically operated models, the operator simply

presses and holds the control button until the leveler

reaches the fully extended position. The operator then

releases the control button and the leveler automatically

lowers to create a good working level with the truck bed.

To retract and restore the leveler, the operator again

pushes the control button until the leveler lip clears the

trailer. Then upon release of the control button, the

leveler will smoothly descend into stored position.

Each of the twin hydraulic cylinders features an

adjustable descent control, eliminating the need for a

mechanical lip latch. This is an exclusive feature and

eliminates lip latch breakage. |

|

|

|

| THE

TOP-OF-DOCK LEVELER |

|

|

Older

docks are typically below the 50" industry

standard height. The trailers bought by major trucking companies match this

industry standard. The Top-Of-

Dock has a 10" upward reach to provide a good

working level on low docks. That, plus the clear

superiority and rugged dependability of levelers, is

why Top-Of-Dock is the overwhelming choice of the

freight handling professionals, the major motor freight

companies, when they work at low docks. They use

the Top-Of-Dock more than all other brands and types

of surface-mounted levelers. |

|

|

|

|

|

|

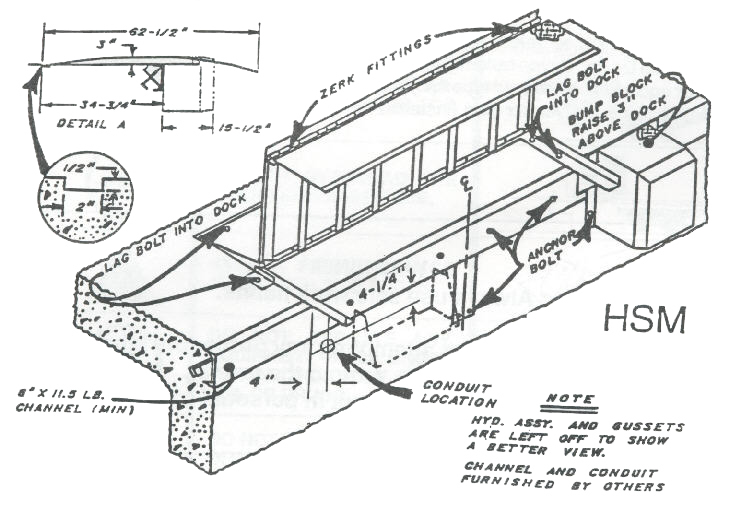

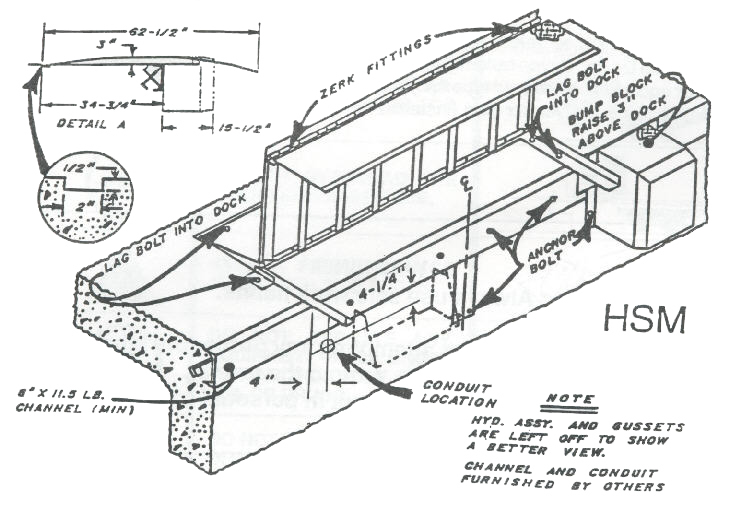

| SIMPLE

INSTALLATION |

|

|

|

Top-Of-Dock

simply mounts to the top and edge of loading dock. In fact, little or no

change is required on an existing

dock. A pit is not needed. For very little expense, Top-Of-Dock allows you

to create and effective working height on

older docks. To reduce loading and unloading grades, it has a generous 63"

span. Deck width is 72". |

|

|

|

| ARCHITECTURAL

SPECIFICATIONS |

|

|

|

Top-Of-Dock

leveler to be fully-electric hydraulic push-button operated with a ____________

lb. capacity, a 72"

deck width, a 15" lip, an 11" extension beyond bumpers, and a

10" upward reach and a 63" total span. Unit to have

two independently adjustable hydraulic cylinders, one on lip and one on

centerplate, for total hydraulic operation with

no mechanical lip latch. Unit to have 120V 1P totally enclosed unitized

pump motor and valve assembly with NEMA

12 push-button control. Unit to automatically return to stored position

after all operations. Unit to mount on top of

dock surface with no concrete pit forming required. Unit to include two

12" x 14" x 18" molded rubber bumpers

secured to fully-welded 5/16" steel bumper blocks. Unit to meet or

exceed all applicable OSHA, ANSI and CS202

requirements. Unit to be Top-Of-Dock leveler model #__________. |

|

| OPTIONS |

|

|

|

|

|

|

17" lip for trailers

with step sections

Rust inhibiting primer paint

Pro-dock brown paint (Machine

Tool Gray

paint is standard)

Key lock operation

Floating bumper block |

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

| PRICES |

| Model No |

Deck

Width |

Total

Unit Width |

20,000 CIR |

25,000 CIR |

30,000 CIR |

35,000 CIR |

| HSM-5 |

72" |

110" |

|

|

|

|

| Wt. |

1050# |

1075# |

1100# |

1125# |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

| Common

"EOD" Options |

| Description |

Price |

| 17" Lip for Refrigerated Trailers |

|

| U.S. Post

Office Model with 3" Run Off Guards (HED only) |

|

| Tapered

Lip (Tapered At Sides) |

|

| Abrasive

Deck Surface Over 4 Way |

|

| Solid Bar

Handle for NeverLift |

|

| Extended

Pipe Handle for Neverlift (Standard on 30k & 35k CIR) |

|

| Low Profile

Design (Flat Center Plate) Pallet-Jack Applications |

|

| Stainless

Steel Hinge Pins |

|

| Cold Spray

Metalized |

Consult

Us |

| Torsion

Spring (Extension Mechanism) DL Series Only |

N/C |

| Extra Heavy

Duty Sliding Bump Block Series Wall Mounting Bracket (1 Pair) (in

lieu of standard) |

|

| Steel Face

Bumpers (1 Pair) (in lieu of standard) |

|

| Laminated

Bumper Blocks (1 Pair, in lieu of standard) |

|

| Special Paint |

Consult

Us |

| Grey Bump

Blocks |

|

|

|

| Common

"EOD" Accessories |

| Model

No |

Description |

Price |

| DL96 |

Dock Ladder 7"x16"x45" with 36" dual grab bar

built into ladder |

|

| DL80 |

Dock Ladder 7"x16"x45" with single grab bar (detached) |

|

| DOTH9260 |

Trash Can Holders |

|

| KIT3650 |

Safety Flag |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

| "EOD" Installation Accessories |

|

| Model

No. |

Description |

Weight |

Price |

DOTH-3816 |

66"

Four-Sided Box Assembly |

235# |

|

DOTH-3836 |

72"

Four-Sided Box Assembly |

250# |

|

DOTH-3851 |

78"

Four-Sided Assembly |

265# |

|

DOTH-3853 |

84"

Four-Sided Assembly |

300# |

|

DOTH-9036 |

Embed

Channel 8" x 120" |

156# |

|

DOTH-9040 |

Embed

Channel 10" x 120" |

175# |

|

DOTH-9050 |

Ramp

Approach Plate 1/4"x12"x120" with 'Break', includes

Anchor Bolts |

170# |

|

DOTH-9051 |

Ramp

Approach Plate 1/4"x18"x120" with 'Break', includes

Anchor Bolts |

226# |

|

DOTH-9052 |

Ramp

Approach Plate 1/4"x24"x120" with 'Break', includes

Anchor Bolts |

338# |

|

DOTH-9054 |

Ramp

Approach Plate 1/4"x36"x120" with 'Break', includes

Anchor Bolts |

164# |

|

DOTH-9055 |

Ramp

Approach Plate 3/8"x12"x120" with 'Break', includes

Anchor Bolts |

246# |

|

DOTH-9056 |

Ramp

Approach Plate 3/8"x18"x120" with 'Break', includes

Anchor Bolts |

327# |

|

DOTH-9057 |

Ramp

Approach Plate 3/8"x24"x120" with 'Break', includes

Anchor Bolts |

612# |

|

DOTH-9059 |

Ramp

Approach Plate 3/8"x36"x120" with 'Break', includes

Anchor Bolts |

897# |

|

DOTH-9060 |

Ramp

Approach Plate 3/8"x48"x120" with 'Break', includes

Anchor Bolts |

900# |

|

DOTH-9072 |

Face

Plate 1/4"x9"x120" with Anchor Bolts |

76# |

|

DOTH-9073 |

Face

Plate 1/4"x12"x120" with Anchor Bolts |

102# |

|

DOTH-9074 |

Face

Plate 1/4"x15"x120" with Anchor Bolts |

127# |

|

DOTH-9066 |

Formed

Angle 1/4"x8"x10"x120" |

151# |

|

DOTH-9067 |

Formed

Angle 1/4"x8"x10"x120" with Break |

151# |

|

DOTH-9068 |

Formed

Angle 1/4"x12"x14"x120" |

217# |

|

DOTH-9069 |

Formed

Angle 1/4"x12"x14"x120" with Break |

217# |

|

| DKIT-9915 |

Installation Kit-included (4) angles 1/4"x2"x2"x6 &

17 Anchor Bolts |

6# |

|

| DKIT-9914 |

TOD Install Kit |

|

|

| DOTH-1003 |

Gray Touch Up Spray Paint |

|

|

| DOTH-1004 |

Orange Touch Up Spray Paint |

|

|

| DOTH-2079 |

Anchor Bolts 5/8"x5" (Round Heads) |

|

|

|

|

DLM, Dock Leveler, Dock Levelers,

Hydraulic Dock Levelers, Loading Dock Levelers, Manual Dock Leveler, Manual

Dock

Levelers, and Top-Of-Dock-Levelers from your complete source for material

handling equipment |

Back

to Product Category |

|

|