|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

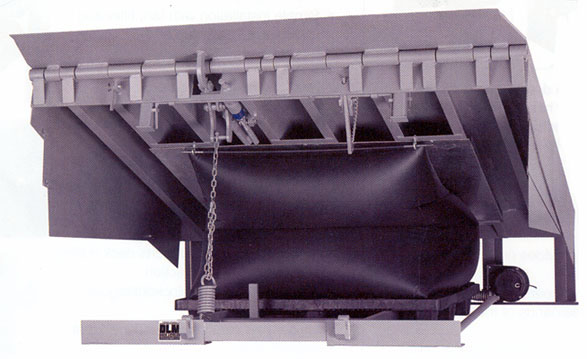

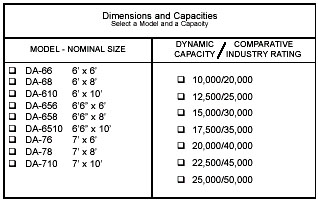

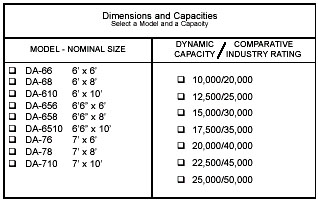

DA

Series Air Powered Dock Leveler

|

The

"DA" Series leveler combines the "push-button" convenience

of hydraulic levelers with the economics of the

mechanical leveler to bring value and performance to your loading dock.

From superior structural design to unlimited

operator features, the "DA" Series air powered leveler is a wise

investment.. |

|

|

|

|

|

|

|

| Standard

Features Include |

|

|

|

• Simple Push Button

Activation

• High Volume, Low Pressure, Activation System

• Four Sided Box Construction - Deck Assembly

• 115 Volt Single Phase Power

• 16" Lip Plate

• Multi-positon Structural Steel Safety Legs

• Below Dock Endloading Control |

|

• Lockout/Tagout Maintenance

Strut

• Night Locks/Cross Traffic Support

• 3-wheel Fork Truck Protection (35k + CIR)

• Lip Supporting Service Strut

• Full Range Toe Guards

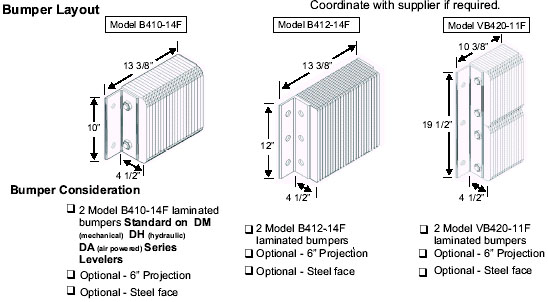

• Two (2) B410-14 Laminated Bumpers |

|

|

|

|

|

|

|

Efficient

Power |

|

•

Low pressure, high volume air

supply.

• 115v single phase motor.

• Simple installation with fan, filter

and "receptacle type" plug end. |

|

|

|

|

|

|

|

|

|

|

| Structurally

Superior |

|

|

|

|

|

|

|

|

•

Over 29" of direct rear hinge support - heaviest in the

industry.

• Four sided box construction provides unmatched struc-

tural integrity.

• Deck construction is capacity dependent to insure your

loading bridge matches the demands of the approved

work load.

• Leveler lip and deck are constructed with high-strength

55,000 lb. yield, safety treadplate.

• Deck support members are application dependent |

|

Unique

Lip Latch |

|

•

Provides reliable lip extension

activation.

• Positive, full height lip extension

for 16", 18" and 20" lip lengths.

• Lip mechanism is fully yieldable in

case of impact with a backing

truck. |

|

|

|

|

|

|

|

|

|

|

|

Deck

& Lip Maintenance Struts |

|

•

Permanently mounted, hinged main-

tenance strut supports deck during maintenance

or inspection.

• Maintenance strut is lockout/tagout

capable.

• Lip support strut permits independent

support of lip. |

|

|

Low Capacity -

Roll form "C" channel

Medium Capacity - Structural "C" channel

Heavy Capacity - Structural "C" channel and "I"

beam |

|

•

Close and consistent spacing of beams provide necessary

support for 3-wheeled and 4-wheeled fork trucks (35k +

CIR). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Multiposition

Safety Legs |

|

|

|

•

Provides free-fall protection should

a truck depart prematurely..

• Safety legs are sized and positioned

to minimize obstructions during

below dock loading operations. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

PRICES

FOR DA SERIES MECHANICAL DOCK LEVELER |

| Size Model No. |

25,000 CIR |

30,000 CIR |

35,000 CIR |

40,000 CIR |

45,000 CIR |

50,000 CIR |

| 6' x 6' |

|

|

|

|

|

|

| DA-66 |

1525# |

1545# |

1625# |

1645# |

1745# |

1765# |

| 6' x 8' |

|

|

|

|

|

|

| DA-68 |

1815# |

1835# |

1915# |

1935# |

2035# |

2055# |

| 6' x 10' |

|

|

|

|

|

|

| DA-610 |

2115# |

2135# |

2215# |

2235# |

2335# |

2355# |

| 6.5' x 6' |

|

|

|

|

|

|

| DA-656 |

1705# |

1725# |

1805# |

2510# |

1925# |

1945# |

| 6.5' x 8' |

|

|

|

|

|

|

| DA-658 |

2030# |

2050# |

2130# |

2150# |

2250# |

2270# |

| 6.5' x 10' |

|

|

|

|

|

|

| DA-6510 |

2380# |

2300# |

2380# |

2400# |

2500# |

2520# |

| 7' x 6' |

|

|

|

|

|

|

| DA-76 |

1745# |

1765# |

1845# |

1865# |

1965# |

1985# |

| 7' x 8' |

|

|

|

|

|

|

| DA-78 |

2055# |

2075# |

2255# |

2175# |

2275# |

2295# |

| 7' x 10' |

|

|

|

|

|

|

| DA-710 |

2370# |

2390# |

2470# |

2490# |

2590# |

2610# |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

PRICES

FOR DA SERIES OPTIONS |

| Description |

Prices |

Nema

12 Controls - N12CB (Interlock Terminals) |

|

Rubber

Weatherseal (Foam Rear) |

|

Brush

Weatherseal (Foam Rear) |

|

Brush

Weatherseal (Brush Rear) |

|

18"

Lip |

|

20"

Lip |

|

| Barrier

Lip Minimum 8'0" Long Levelers with 5" high barrier |

|

| 24" Pit Conversion (Factory Installed) |

|

|

|

| Description |

Prices |

| Yellow

Toe Guards |

|

| Yellow

& Black Toe Guard Safety Type |

|

| Grease

Fittings |

|

| Smooth

Deck & Lip |

|

| Abrasive

Finish on Deck & Lip (Includes Smooth Deck & Lip) |

|

| Abrasive

Finish on Deck & Lip (On 4 Way Checker Plate) |

|

| Full

Range Toeguards |

|

| B2

Barrier Lip (Smooth Transition with Debris Screen) |

|

| Extended

Lip Chamfer (3") |

|

| Reduced

Lip Crown (Range +6" - 8") |

|

| 3-Wheel

Fork Truck Protection (Optional for 20k thru 30k) |

|

| Rubber

Weatherseal (Rear Foam) |

|

| Brush

Weatherseal (Rear Foam) |

|

| Brush

Weatherseal (Rear Brush) |

|

| 24"

Pit Conversion (blocked and elevated frame) |

|

| 18"

Lip |

|

| 20"

Lip |

|

| Foam

Insulated Deck |

|

| Stainless

Steel Hinge Pins (Front and rear) |

|

| Special

Paint Requirements (Optional) |

Consult

us |

| Spray

Metalized (Deck, Lip & Frame) |

|

| Gray

Touch-up Spray Paint |

|

| Yellow

Touch-up Spray Paint |

|

|

|

|

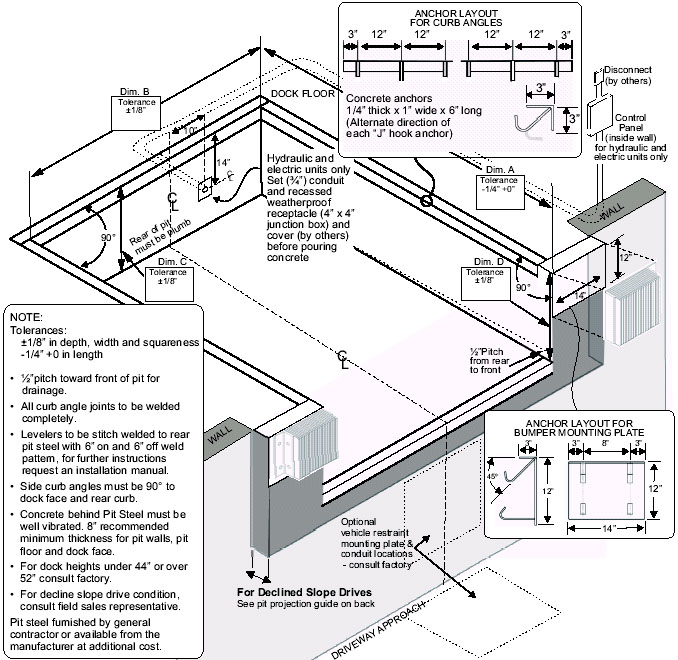

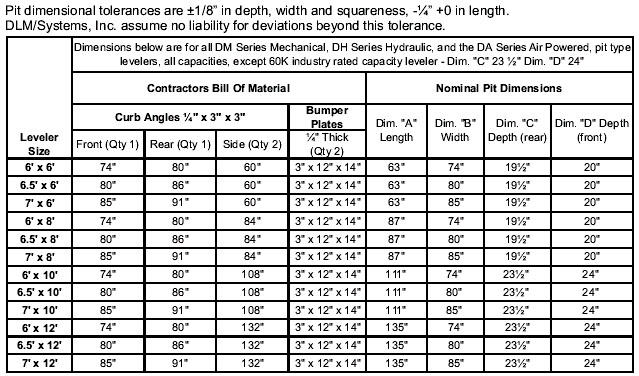

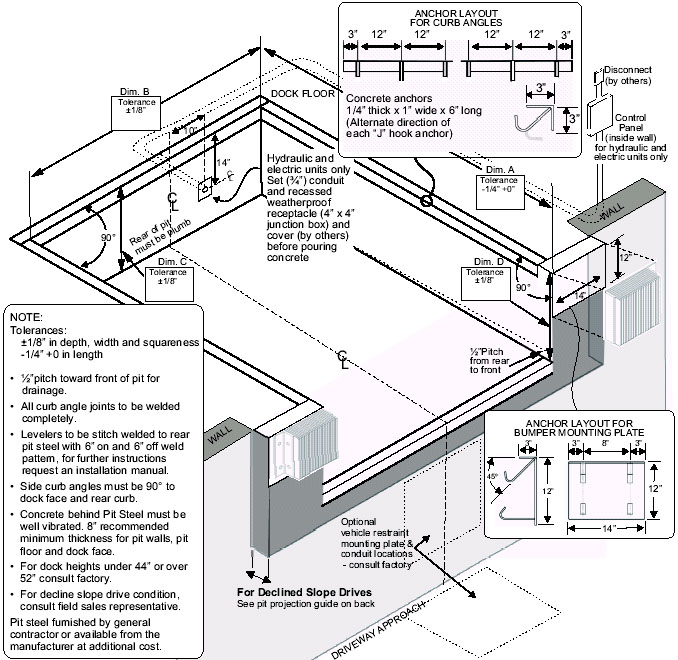

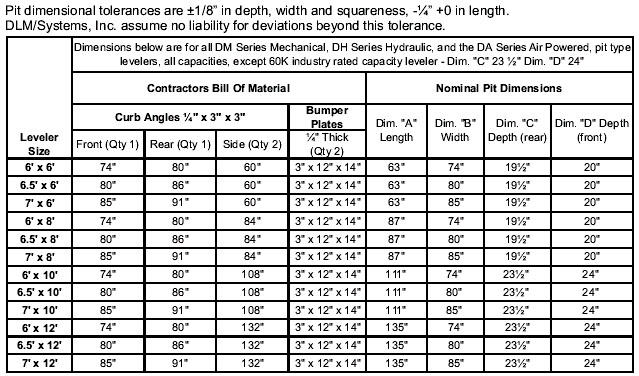

PIT

DETAIL |

|

|

|

|

|

|

|

|

|

Pit

dimensional tolerances are ±1/8” in depth, width and squareness,

-¼” +0 in length.

We assume no liability for deviations beyond this tolerance. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Optional

Bumper Plates - in lieu of above |

|

|

|

|

11”

wide x 20” high (Qty 2)

11” wide x 24” high (Qty 2)

Other Bumper Embed ___________________ (Qty 2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Pit

Projection Guide for Decline Slope Driveways |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rise

of

Driveway |

|

|

|

|

|

|

|

|

|

|

|

|

|

Percentage

Of Grade = |

|

|

Driveway

Length |

|

|

|

|

|

|

NOTE: Projection of pit may require modifications to seals and shelters.

Coordinate with supplier if required. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

PRICES

FOR DA SERIES STEEL EMBED ITEMS |

| Size |

4 Piece Angle/2 Piece

Bumper Plates

Recommended |

6 Piece Angle |

3 Sided Rapid

Form Pit Kit |

4 Sided Box |

| 6' x 6' |

|

|

|

|

| Wt. |

201# |

204# |

350# |

430# |

| 6' x 8' |

|

|

|

|

| Wt. |

233# |

236# |

450# |

530# |

| 6' x 10' |

|

|

|

|

| Wt. |

262# |

265# |

615# |

695# |

| 6' x 12' |

|

|

|

|

| Wt. |

292# |

295# |

760# |

840# |

| 7' x 6' |

|

|

|

|

| Wt. |

215# |

218# |

370# |

450# |

| 7' x 8' |

|

|

|

|

| Wt. |

245# |

248# |

540# |

620# |

| 7' x 10' |

|

|

|

|

| Wt. |

277# |

280# |

720# |

800# |

| 7' x 12' |

|

|

|

|

| Wt. |

306# |

309# |

890# |

970# |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to

purchase. |

|

|

|

|

| Description |

Price |

Hot

Dip Galvanized Angles |

Consult us |

Two

(2) 11 x 20 Bumper Plates in Lieu of Standard Height Plates |

|

Two

(2) 11 x 24 Bumper Plates in Lieu of Standard Height Plates |

|

Restraint

Embed |

|

Bracket

Pit Floor Plate |

|

Bumper

Mounting plate for 3 sided box |

|

| Rear Pit Spacers (Factory Install) |

1"

& 2" |

|

3"

& 4" |

|

5"

& 6" |

|

7"

& 8" |

|

9"

& 10" |

|

| Pit Conversions (pit depth) |

1"

- 4" (Pit From 19 1/2" - 23 1/2") Factory Installed |

|

5"

- 8" |

|

9"

- 12" |

|

| Free Standing Frame With Bumper Supports |

6' Long |

|

8' Long |

|

10'

Long |

|

12'

Long |

|

| Deep Pit Stands (Bumpers Excluded) |

6' Long |

|

8' Long |

|

10'

Long |

|

12'

Long |

|

| Run

Off Guard |

|

|

| *Note

may require additional Freight |

|

| Note:

For 6.5' use 7' price |

|

|

Specifications |

|

|

|

|

|

| GENERAL

DESCRIPTION: |

|

STANDARD

OPERATIONAL FEATURES: |

All

DA Series dock levelers incorporate the use of a low

pressure, high volume air system to raise and lower the

platform. Unit conforms to OSHA, U.S. Department of

Commerce Standard CS-202-56 and is manufactured

in compliance with the American National Standard of

Safety Performance and Testing of Dock Leveling

Devices (ANSI) MH 30.1. |

|

|

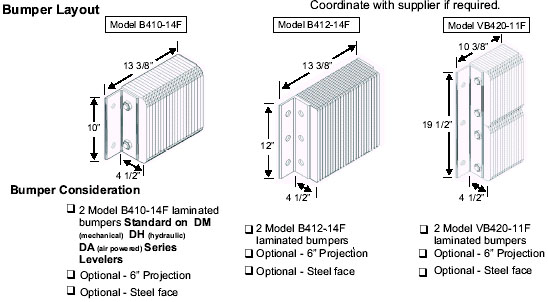

The

DA Series Leveler is controlled remotely from wall

mounted control panel. An array of optional control panel

features are available. Service range is from 12” above

to 12” below dock level. Lip keepers welded to frame

members provide nighttime security and crosstraffic

support. Full operating range toe guards are provided as

standard. Maintenance prop with ‘Lock-out Tag-out’

capability is provided as standard. Factory finish includes

rust inhibitive prime coat industrial grade finish. Special

coating and colors are optional. Each leveler is shipped

with two (2) (B 410-14) 4½” thick x 10”h x 14”w

laminated bumpers as standard. |

|

|

|

| CONSTRUCTION: |

|

The

platform is constructed of ¼” thick 4-way high

tensile 50,000 minimum yield A572 steel safety tread-

plate (3/16” for 20,000 Comparative Industry Rating

(CIR)). Platform is reinforced and supported by full-

length roll formed “C” channels (20,000, 25,000 and

30,000 lb CIR), structural “C” channels (35,000 &

40,000 lb CIR), and a combination of structural “C”

channels and “I” beams (45,000 and 50,000 lb CIR).

Front and rear header plate is ½” x 7” hot rolled steel.

DA Series lips are made of 4-way safety tread-plate,

the 20,000 and 25,000 lb CIR are 1/2” thick, the

30,000, 35,000 and 40,000 lb CIR are 5/8” thick,

and the 45,000 and 50,000 lb CIR are 3/4” thick.

The standard lip length is 16” on all capacities. Hinge

tubes are 1 3/4” OD x 5/16” wall, 1 7/8” x 3/8” wall,

or 2 1/8” x ½” wall, depending upon CIR. All lip hinge

pins are 1” M1044 steel. Steel lip gusset are standard

on 50,000 lb CIR models. Steel header gussets are

standard on all models 35,000 lb CIR and above.

All platforms are designed to compensate for up

to 4” of canted truck beds. |

|

|

|

|

|

ELECTRICAL: |

|

Electric

blower motor shall be 115v single phase,

1400 watt drawing 11 amps at startup. Optional

voltage motors are available, consult factory.

Electrical control panel is non-metallic Nema 4

enclosure. All electrical components, connections

and wiring are UL listed or recognized. Please

Note: Unless specifically noted on quotation, all

electrical requirements are the responsibility of others. |

|

|

|

|

WARRANTY: |

|

All DA Series models feature

a full one (1) year base

warranty on all structural, pneumatic and electrical parts,

including freight and labor charges in accordance with Standard Warranty

Policy. Lifting system, including air

bladder, seals, hoses and motor carry an additional full

four (4) year warranty on parts and labor. Structural

components carry and additional nine (9) year pro-rated

warranty. Warrants all components to be free of defects

in materials and workmanship, under normal use, during

the warranty period. This base warranty period begins

upon the completion of installation or the sixtieth (60th)

day after shipment, whichever is earlier. Additional

warranty extensions may be available upon approved

submittal of application information. |

|

|

|

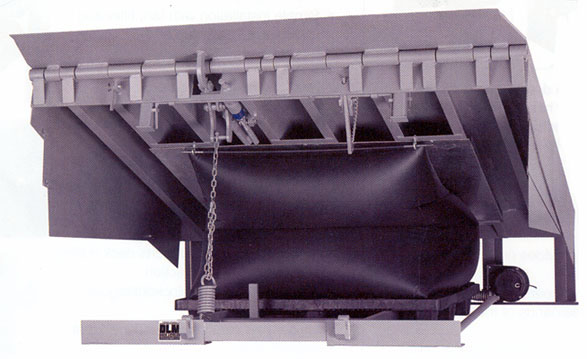

| OPERATION: |

|

Platform

is raised by an electric blower motor filling an

air bladder which provides upward lift of the platform.

The lip is extended and secured in place with Lip

Drive™ positive lip extension. Releasing the raise button

allows the platform to float downward to the truck bed.

No manual lifting is required. Elevated, frame mounted

air bladder assembly keeps clear of debris accumulated

in the pit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

DLM, Dock Leveler, Dock Levelers,

Loading Dock Leveler, Loading Dock Levelers, Pit Mount Dock Leveler, Pit

Mount Dock

Levelers, Pit Mounted Dock Leveler, and Pit Mounted Dock Levelers from

your complete source for material handling equipment. |

Back

to Product Category |

|

|