|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back

to Product Category

CONCRETE

ROUND 4 SEAT TABLE

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

|

|

Simple

lines and colors make these tables an

excellent choice for an outdoor café or park

area. High quality, low maintenance. |

|

|

|

|

|

Accepts

optional umbrella without extra stand.

New and improved for easier assembly.

Supersedes TF3125. Also available in two

seat and three seat models. ALSO--

REFINISHING KIT: TF3315 Make your

table look NEW!! All the materials you need

to refinish your concrete tables, benches, and

seats to restore them to like new condition. |

|

|

|

|

|

|

|

|

|

|

|

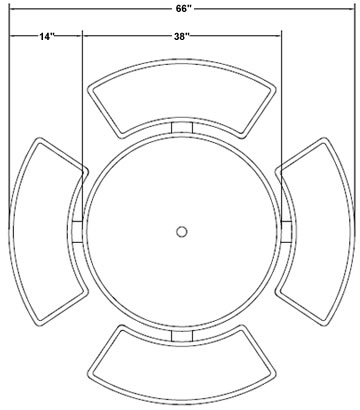

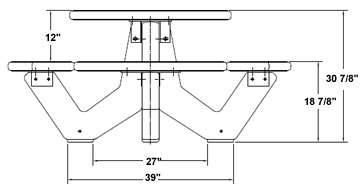

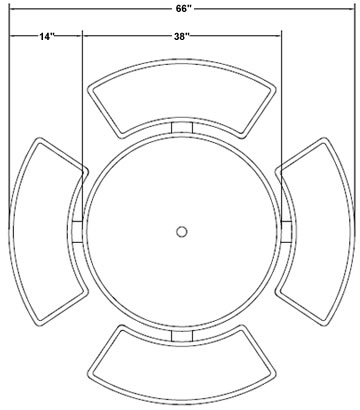

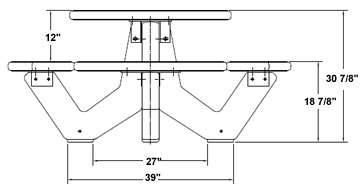

Size: 66" Dia. x 30" H installed.

Weight: 1100 lbs.

Seating Capacity: 8 persons.

Material: Reinforced concrete.

Colors: See Options.

Reinforcing: 1/4” & 3/8" Dia. steel rebar.

Hardware: (1)- table-to-leg bracket. |

|

|

(8)-

seat-to-leg brackets.

(8) - 3/8" Dia. x 5 1/2" hex screws.

(16) - 3/8” x 7/8” O.D. Flatwashers

(8) - 3/8" locking hex nuts.

(4) - Neoprene Pads.

(24) - 3/8" Dia. x 1-1/4" hex flange

screws.

(1) - 1/8” x 3” Keeper Pin. |

|

|

|

|

|

|

|

|

|

PRICE: $1,900.00 |

|

|

|

|

|

|

|

|

|

|

| Table

Refinishing Kit: TF3315 $198.50 |

|

|

|

|

|

|

|

|

|

|

This

Quick Ship table is available in 2 colors -

Standard Ground & Polish top and bench with Acid Wash legs

in Sand or Gray. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frame

(legs): (1) - top interlocking leg.

(1)

- bottom interlocking leg. |

|

|

Assembly: Do not over tighten bolts or inserts

will pull out. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maintenance: Periodically rinse with water

and mild detergent. Reseal annually. |

|

Top: (1) - 38" Dia. x 2".

Benches: (4) - benches 34" L x 12" W x 2" H. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Packaging: Packaged unassembled in

crate, and shrink wrapped in plastic. |

|

Optional

Anchoring: (4) - 3/8" x 1-1/2"

inserts (angle brackets not provided). |

|

|

|

|

|

|

|

|

|

|

|

Standard: (1) - 1-9/16" Dia. x 2" pop-out plug

in table top for umbrella pole. |

|

|

|

|

|

|

|

Available

Colors |

|

|

|

Refinishing

Ground & Polished Concrete Instructions |

|

|

|

|

|

|

|

| Kit

Includes: |

|

|

|

|

|

-

2 lbs Grout Mixture

- 10 oz Bonding Agent

- 4 Spray Cans of Sealer |

|

|

|

|

|

|

|

|

|

| Additional

Items Needed: |

|

|

|

-

Rubber Gloves

- #240 Sand Paper

- Sanding Block

- Mixing Tool

- Scrubbing Pad |

-

#80 Grit Sand Paper

- Pail

- Sponge

- Squeegee |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note:

Wear rubber gloves during entire refinishing process. Refinishing results

are best

when all excess grout is removed and surface is sanded smooth. Check for

and clean up

spills after each step. Newly refinished tables will retain an attractive

appearance for

several years if they are resealed at least once a year. |

|

|

|

|

|

|

|

1.

Scrub and Rinse

Rinse surface with water while using scrubbing pad to

remove dirt and grime. Using the sanding block and

#80 sand paper, sand surface. Repeat rinse. |

|

2.

Grout

Mix grout and bonding agent together to create

a creamy consistency in a pail. Allow to set for

5 minutes Apply to the surface using a circular

motion, with a sponge to fill all voids. Can

be used on smooth edges, not on acid wash

surfaces. |

|

|

|

|

|

|

Note: Acid wash edges to be taped off before groutin

the surface to avoid getting grout in pores of edge. |

|

|

|

|

|

3.

Remove Excess Grout

Immediately remove all excess grout with a squeegee.

Apply water as needed to keep grout moist with a spray

bottle. Thoroughly inspect the surface to be certain it is

clean. Allow to cure for approximately 24 hours. |

4. Wet-Sand

Once the surface has cured, wet-sand grouted

surface using sanding block, #240 sandpaper

and water. |

|

|

|

|

|

|

|

|

|

5. Clean

Thoroughly rinse with water and allow to dry. Surface

must be dust free. If tape was needed for edges

remove tape before cleaning the surface. |

|

4. Wet-Sand

Once the surface has cured, wet-sand grouted

surface using sanding block, #240 sandpaper

and water. |

|

|

SPECIFICATION |

|

|

|

|

|

1.1

SUMMARY

A. Section includes: Furnish Precast Concrete Table

indicated on drawings or specified

herein. |

|

1.2

REFERENCES

A. American Society for Testing & Materials

1. ASTM C33 2. ASTM C150 3. ASTM C31 |

|

1.5

SUBMITTALS

A. Submit product data, shop drawings and Samples.

1. Product Data: Manufacturer's specifications

and

technical data edited

specifically for proposed

system, including

the following specific information:

a. Detailed specification

of construction fabrication.

b. Manufacturer's

installation instructions

c. Maintenance literature

d. Product warranty

2. Shop Drawings: Indicate pertinent

dimensions,

general construction,

component connections

anchoring methods, hardware

and installation

procedures.

3. Samples as requested by Architect. |

|

1.6

QUALITY ASSURANCE

A. Qualifications of Manufacturer: Manufacturer to be

pre-qualified by specifier prior to

bidding. Failure to

comply will result in disqualification

of bid. Manufacturer

to have at least five years experience

in the manufacturer

of precast concrete tables field proven

for at least five

years. |

|

|

|

|

|

1.10

WARRANTY

Manufacturer shall submit a written warranty for

precast products for the period of two years upon

acceptance of products. |

|

2.2

MATERIALS

A. Portland Cement: ASTM C150 specifications for

Portland Cement.

B. Aggregates: All aggregates to meet ASTM C33

specifications, to be cleaned of foreign

matter and

properly graded to size.

C. Coloring: Pigments used shall be inorganic, resistant

to alkalinity and used as per manufacturers

recommendations. |

|

|

|

|

Concrete Round Table, Concrete

Tables, Park Furnishings, Tables, Concrete and Steel Tables, Plastic Picnic

Table,

Polysteel Tables, Site Amenities, Site Furnishings, Steel Tables, and

Street Furniture from your source for material

handling equipment. |

Back

to Product Category |

|

|