|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

91

SERIES KINGPINLESS STYLE

20,000 LB. MAXIMUM CAPACITY |

|

|

|

|

|

BENEFITS |

|

|

|

|

|

|

|

|

|

|

|

|

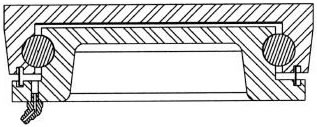

The

raceways of the 91 Series kingpinless style casters

are precision machined and then through hardened to

eliminate brinelling of the surface. This unique swivel

design allows the main caster bearing to operate in

shear where the load and thrust forces bear on the

7/8” diameter ball bearings. The 91 Series offers a

high strength swivel section that will easily swivel under

extreme loads. |

|

|

|

|

|

|

|

|

|

|

|

|

FEATURES |

|

|

|

Swivel

Section: Constructed of hot forged C-1045

steel, the single ball race design features 7/8” diameter

load/thrust ball bearings in a 7” diameter precision

machined load raceway

Legs: 1/2” x 4” legs are formed and continuously

welded both inside and outside for greater strength.

Kingpin: Kingpinless style design.

Axle: 1-1/4”, Grade 5.

Lubrication: Pre-lubricated before shipping.

Wheels: 6” to 18” diameter wheels, 3” to 5” widths.

Finish: Gold dichromatic plating.

Standard: Shielded swivel to reduce dust and dirt

contamination. |

|

|

Swivel

#91-12409-65-1LP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

APPLICATIONS |

|

|

|

|

|

|

|

|

Specifi

cally designed for severe applications, the 91

Series is ideal for die carts, tooling fi xtures, aircraft

engine stands, ground support equipment, aerospace

A-frame skin dollies, portable jigs, large work platforms,

mobile military equipment, aircraft maintenance stands

and production line delivery trailers. |

|

SEE

BELOW FOR

PRICES |

|

|

|

|

|

|

|

|

|

| Rigid

#90-10509-65-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

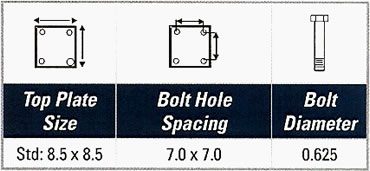

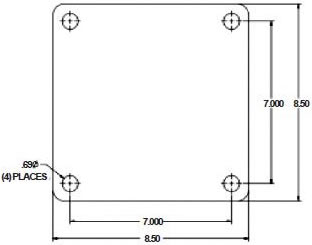

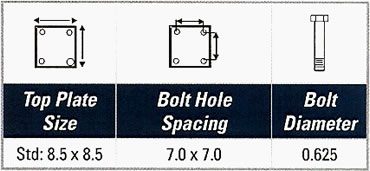

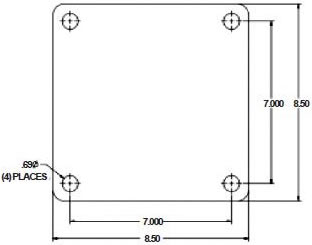

Top

Plate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

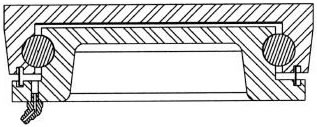

Cross

Sectional View |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHEELS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Forged

Steel |

|

Polyurethane |

|

Mold On

Rubber |

|

70D Hard

Polyurethane |

|

Cast Iron |

|

Phenolic |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Cast

Iron Wheels Description: |

|

|

|

|

Phenolic

Wheels Description: |

These

cast iron wheels are constructed of premium Class

30 gray iron for maximum load capacity and impact

strength. Each wheel is precision machined with rounded

edges to finished tolerances. All 1 ½” and 2” wide wheels

with ¾” roller bearings are supplied with ½” spanner

standard. The wheels feature heavy cross section castings

for heavy duty use, abrasion resistance and a long service

life. Built for high capacity applications, the cast iron

wheels can withstand extreme heat. Precision tapered

bearings are available to complement the characteristics

of the wheels. |

|

|

|

A

wide selection of phenolic resin wheels are available

in inventory. The wheels shown in the chart are

laminated phenolic. Standard black phenolic wheels

(30) feature macerated canvas duck compression

molded with premium phenolic resins to produce a

value/price relationship. High temperature phenolic

wheels (32) provide continuous service up to 425°

Fahrenheit and intermittently to 500° Fahrenheit. Lam-

inated phenolic wheels (35) feature a continuous wound

tread with a macerated canvas center. The wheels have

a 40% higher impact resistance and carry up to 25%

higher load than standard phenolic wheels. Phenolic

wheels are excellent for waste bins, platform trucks,

heavy material handling, autoclaves, baking ovens, and

high temperature bakery applications.

Bearings: Precision ball, delrin, straight roller and

tapered.

Standard: All 1-1/2” and 2” wide wheels with 3/4”

roller bearings are supplied with 1/2” spanner standard. |

|

|

|

|

|

|

|

|

|

| Polyurethane

Wheels Description: |

|

|

|

|

Made

from Caster Concepts standard durometer 95A

polyurethane is easily identified by its maroon color.

Wheels are available in a standard profile thickness as

well as heavy duty (H.D.) 1 inch thick tires providing

increase maximum weight capacity. This material is

economical, provides lower rolling resistance than

rubber wheels and is floor protective. Sealed precision

ball bearings for the lowest rolling resistance for

ergonomic applications. Roller bearings when a low-

cost anti-friction bearing is required. Tapered bearings

for applications where towing and capacity are present.

Delrin bearings for wet applications where light loads

and infrequent movement is present; Oilite bearings for

low cost friction bearing where heat, moisture, infrequent

movement or lighter loads are part of the application. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

70D

Hard Polyurethane Wheels Description: |

|

|

|

Processed

in-house, elastomers provide flexibility in

material choice, hardness, and finished size. Caster

Concepts is adept at processing MDI polyesters,

and TDI polyesters and polyesters, in a wide range of

durometers from 50 durometer shore A to 70

durometer shore D scale. |

|

|

|

|

|

|

|

|

|

|

|

Mold

On Rubber Wheels Description: |

|

|

|

|

|

|

|

|

|

| Forged

Steel Wheels Description: |

|

|

|

|

Caster Concepts offers the

highest quality domestic Mold

On Rubber wheels. Our mold-on rubber wheels consist

of a soft black, 70 durometer rubber tread permanently

bonded Class 30 gray iron centers. Mold on rubber

wheels provide excellent floor protection, a cushioned

and quiet ride for the product being transported, and they

absorb shock and vibration.

Bearings: Delrin, oilite, roller, precision ball, tapered.

Temperature: Maximum to 180° F

Durometer: 70 Durometer Shore A

Standard: All 1-1/2” and 2” width wheels with 3/4”

roller bearings are supplied with 1/2” spanner bushing. |

Forged

steel wheels are hot forged from high carbon steel billets heated to 2,400

degrees then repeatedly hit by high tonnage forging hammers. This forging

process enhances

the grain structure and increases the ductility and tensile

strength (64000 psi) of the wheel. The wheels are then

precision machined flat with rounded edged to finished

tolerances. Wheel material codes: forged steel (20);

heavy duty forged steel (21); ductile iron. Forged steel

wheels offer the greatest load capacity, impact strength

and roll ability of all caster wheels. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

OPTIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Other

Options Available Upon Request |

|

|

Poly

Cam Brake (P) |

Brakes:

Poly Lock:.....................................................P*

Wrap Around: ..............................................W*

Face Contact:.................................................F

Swivel Locks:

Factory Installed: ............................................L

Heavy Duty:...................................................HDL

Demountable: ................................................DL

Heavy Duty Demountable:.............................DHDL

Sealed Swivel: ..............................................SSW

Sealed Wheels: .............................................SW

Toe Guard: ...................................................TG

*For wheels with diameter >6 |

|

|

A

polyurethane cam roller engages a steel brake shoe

against the tread of the wheel providing positive engage-

ment of the tread. Levers can be mounted toe out

(shown) or reversed to toe in. |

|

|

|

|

|

|

|

|

|

|

|

Heavy

Duty Swivel Lock (HDL) |

|

|

|

|

The

heavy duty swivel lock provides a longer, more

accessible handle made from machined steel. |

|

|

|

|

|

|

|

|

|

|

|

Factory

Installed Swivel Lock (L) |

|

|

The

swivel lock provides notches every ninety degrees for

use in straight line movement of the cart. Also available in

1, 3 or 8 position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

SWIVEL

CASTER PRICES |

Model

No. |

Wheels |

Capacity |

Wt.

(lbs) |

Std.

Prices |

Dia.

(in) |

Width

(in) |

Description |

Roller

Bearing |

Tapered

Bearing |

OAH

(in) |

Swivel

Lead (in)

| Swivel

Radius (in)

|

|

6 |

3 |

Forged

Steel |

6,000 |

~ |

9.5 |

2.25 |

5.46 |

60 |

$981 |

|

6 |

3 |

H.D.

Forged Steel |

~ |

17,000 |

9.5 |

2.25 |

5.46 |

60 |

$951 |

|

6 |

4 |

H.D.

Polyurethane |

3,000 |

~ |

9.5 |

2.25 |

3 |

60 |

$996 |

|

8 |

4 |

Forged

Steel |

8,400 |

~ |

11 |

2.25 |

6.56 |

73 |

$1,086 |

|

8 |

4 |

H.D.

Forged Steel |

~ |

20,000 |

11 |

2.25 |

6.56 |

73 |

$1,161 |

|

8 |

4 |

Polyurethane |

3,800 |

~ |

11 |

2.25 |

6.56 |

63 |

$975 |

|

10 |

4 |

Forged

Steel |

8,400 |

~ |

13 |

2.5 |

7.76 |

83 |

$1,287 |

|

10 |

4 |

H.D.

Forged Steel |

~ |

20,000 |

13 |

2.5 |

7.76 |

83 |

$1,344 |

|

10 |

4 |

Polyurethane |

4,200 |

~ |

13 |

2.5 |

7.76 |

59 |

$1,128 |

|

10 |

4 |

H.D.

Polyurethane |

5,000 |

~ |

13 |

2.5 |

7.76 |

68 |

$1,143 |

|

10 |

4 |

Mold

On Rubber |

1,500 |

~ |

13 |

2.5 |

7.76 |

66 |

$909 |

|

10 |

5 |

H.D.

Polyurethane |

6,000 |

~ |

13 |

2.5 |

7.91 |

68 |

$1,356 |

|

10 |

5 |

70D

Hard Polyurethane |

7,200 |

~ |

13 |

2.5 |

7.91 |

68 |

$1,326 |

|

12 |

4 |

Ductile

Iron |

7,500 |

~ |

15.5 |

2.5 |

8.73 |

90 |

$1,830 |

|

12 |

4 |

H.D.

Polyurethane |

5,500 |

~ |

15.5 |

2.5 |

8.73 |

75 |

$1,215 |

|

12 |

4 |

70D

Hard Polyurethane |

6,600 |

~ |

15.5 |

2.5 |

8.73 |

75 |

$1,221 |

|

12 |

4 |

Mold

On Rubber |

1,600 |

~ |

15.5 |

2.5 |

8.73 |

71 |

$1,038 |

|

12 |

5 |

Ductile

Iron |

10,000 |

~ |

15.5 |

2.5 |

8.86 |

135 |

$2,019 |

|

12 |

5 |

H.D.

Polyurethane |

6,250 |

~ |

15.5 |

2.5 |

8.86 |

90 |

$1,398 |

|

12 |

5 |

70D

Hard Polyurethane |

7,800 |

~ |

15.5 |

2.5 |

8.86 |

90 |

$1,428 |

|

12 |

5 |

Mold

On Rubber |

1,850 |

~ |

15.5 |

2.5 |

8.86 |

88 |

$1,290 |

|

14 |

5 |

Cast

Iron |

7,000 |

~ |

17.5 |

3 |

10.31 |

100 |

$1,317 |

|

16 |

4 |

Laminated

Phenolic |

8,400 |

~ |

19 |

3 |

11.18 |

80 |

$1,854 |

|

16 |

4 |

H.D.

Polyurethane |

6,000 |

~ |

19 |

3 |

11.18 |

109 |

$1,530 |

|

16 |

4 |

Mold

On Rubber |

1,450 |

~ |

19 |

3 |

11.18 |

106 |

$1,506 |

|

16 |

4 |

Cast

Iron |

7,500 |

~ |

19 |

3 |

11.18 |

110 |

$1,443 |

|

16 |

5 |

H.D.

Polyurethane |

8,000 |

~ |

19 |

3 |

11.28 |

115 |

$1,704 |

|

16 |

5 |

70D

Hard Polyurethane |

8,000 |

~ |

19 |

3 |

11.28 |

115 |

$1,782 |

|

18 |

5 |

H.D.

Polyurethane |

8,500 |

~ |

21 |

4 |

13.24 |

125 |

$1,953 |

|

18 |

5 |

70D

Hard Polyurethane |

9,000 |

~ |

21 |

4 |

13.24 |

125 |

$1,968 |

|

Capacity listed is

for manual operation. For powered operations, please contact us.

All dimensions are in inches. All weights are in pounds. |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

RIGID

CASTER PRICES |

Model

No. |

Wheels |

Capacity |

Wt.

(lbs) |

Prices |

Dia.

(in.) |

Width

(in.) |

Material |

Roller

Bearing |

Tapered

Bearing |

OAH

(in.) |

Rigid

Lead (in.)

| Rigid

Radius (in.)

|

|

6 |

3 |

Forged

Steel |

6,000 |

~ |

9.5 |

2.25 |

5.46 |

45 |

$681 |

|

6 |

3 |

H.D.

Forged Steel |

~ |

17,000 |

9.5 |

2.25 |

5.46 |

45 |

$651 |

|

6 |

4 |

H.D.

Polyurethane |

3,000 |

~ |

9.5 |

2.25 |

3 |

45 |

$696 |

|

8 |

4 |

Forged

Steel |

8,400 |

~ |

11 |

2.25 |

6.56 |

58 |

$786 |

|

8 |

4 |

H.D.

Forged Steel |

~ |

20,000 |

11 |

2.25 |

6.56 |

58 |

$861 |

|

8 |

4 |

Polyurethane |

3,800 |

~ |

11 |

2.25 |

6.56 |

48 |

$675 |

|

10 |

4 |

Forged

Steel |

8,400 |

v |

13 |

2.5 |

7.76 |

68 |

$987 |

|

10 |

4 |

H.D.

Forged Steel |

~ |

20,000 |

13 |

2.5 |

7.76 |

68 |

$1,044 |

|

10 |

4 |

Polyurethane |

4,200 |

~ |

13 |

2.5 |

7.76 |

44 |

$828 |

|

10 |

4 |

H.D.

Polyurethane |

5,000 |

~ |

13 |

2.5 |

7.76 |

53 |

$843 |

|

10 |

4 |

Mold

On Rubber |

1,500 |

~ |

13 |

2.5 |

7.76 |

51 |

$609 |

|

10 |

5 |

H.D.

Polyurethane |

6,000 |

~ |

13 |

2.5 |

7.91 |

53 |

$1,056 |

|

10 |

5 |

70D

Hard Polyurethane |

7,200 |

~ |

13 |

2.5 |

7.91 |

53 |

$1,026 |

|

12 |

4 |

Ductile

Iron |

7,500 |

~ |

15.5 |

2.5 |

8.73 |

75 |

$1,530 |

|

12 |

4 |

H.D.

Polyurethane |

5,500 |

~ |

15.5 |

2.5 |

8.73 |

60 |

$915 |

|

12 |

4 |

70D

Hard Polyurethane |

6,600 |

~ |

15.5 |

2.5 |

8.73 |

60 |

$921 |

|

12 |

4 |

Mold

On Rubber |

1,600 |

~ |

15.5 |

2.5 |

8.73 |

56 |

$738 |

|

12 |

5 |

Ductile

Iron |

10,000 |

~ |

15.5 |

2.5 |

8.86 |

120 |

$1,719 |

|

12 |

5 |

H.D.

Polyurethane |

6,250 |

~ |

15.5 |

2.5 |

8.86 |

75 |

$1,098 |

|

12 |

5 |

70D

Hard Polyurethane |

7,800 |

~ |

15.5 |

2.5 |

8.86 |

75 |

$1,128 |

|

12 |

5 |

Mold

On Rubber |

1,850 |

~ |

15.5 |

2.5 |

8.86 |

73 |

$990 |

|

14 |

5 |

Cast

Iron |

7,000 |

~ |

17.5 |

3 |

10.31 |

85 |

$1,017 |

|

16 |

4 |

Laminated

Phenolic |

8,400 |

~ |

19 |

3 |

11.18 |

65 |

$1,554 |

|

16 |

4 |

H.D.

Polyurethane |

6,000 |

~ |

19 |

3 |

11.18 |

94 |

$1,230 |

|

16 |

4 |

Mold

On Rubber |

1,450 |

~ |

19 |

3 |

11.18 |

91 |

$1,206 |

|

16 |

4 |

Cast

Iron |

7,500 |

~ |

19 |

3 |

11.18 |

95 |

$1,143 |

|

16 |

5 |

H.D.

Polyurethane |

8,000 |

~ |

19 |

3 |

11.28 |

100 |

$1,404 |

|

16 |

5 |

70D

Hard Polyurethane |

8,000 |

~ |

19 |

3 |

11.28 |

100 |

$1,482 |

|

18 |

5 |

H.D.

Polyurethane |

8,500 |

~ |

21 |

4 |

13.24 |

110 |

$1,653 |

|

18 |

5 |

70D

Hard Polyurethane |

9,000 |

~ |

21 |

4 |

13.24 |

110 |

$1,668 |

|

Capacity

listed is for manual operation. For powered operations, please contact us.

All dimensions are in inches. All weights are in pounds. |

|

Caster, Wheels, Casters,

Floor Locks, Heavy Duty Casters, Medium Duty Casters, Pneumatic Casters,

Rigid Casters, Rubber

Wheel Casters, and Swivel Casters from your source for material handling

equipment. |

Back

to Product Category |

|

|