|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

PLUG

AND PLAY CRANE KIT PACKAGE |

|

|

|

|

Components

to build with - Just

add a beam |

|

|

Our crane kit packages include

high-perfor-

mance components, that when coupled with a

bridge beam, easily handle the most demanding

CMAA class “C” crane applications. Top run-

ning kits are available in 1 through 10 Ton 20'

– 60' span and underhung are available in 2

through 5 Ton 20' – 50' span. |

|

|

|

|

|

Included

in Crane Kit Packages |

|

|

•

End Trucks – 40 or 80 FPM with 3-step VFD

control

• Hoist and Trolley – Dual speed or 2-step, VFD

controlled

• Lift – 20 foot

• Chain Container – Canvas

• Beam Accessory Kit – Includes all braces,

mounting plates, guide wire brackets, end

stops, control panel brackets, hardware and

instructions

• Bridge Control Panel – With UL listed Power

Electronics® VFD control panel with plug and

play connections for end trucks

• Crane Wiring – Complete package

• Flat Cable Festooning – Complete package

for power and roving pendant

• Pendant – 8-button with on/off

• Voltage – 460-3-60 |

|

|

|

| Trolley

Hoist Models |

|

|

•

1 Ton: NERM010LD-SD

• 2 Ton: NERM020LD-SD

• 3 Ton: NERM030CD-SD

• 5 Ton: NERM050LD-SD |

|

|

|

|

|

| FREE

SHIPPING IN CONTINENTAL USA |

|

|

TROLLEY

HOIST |

|

|

|

|

|

|

|

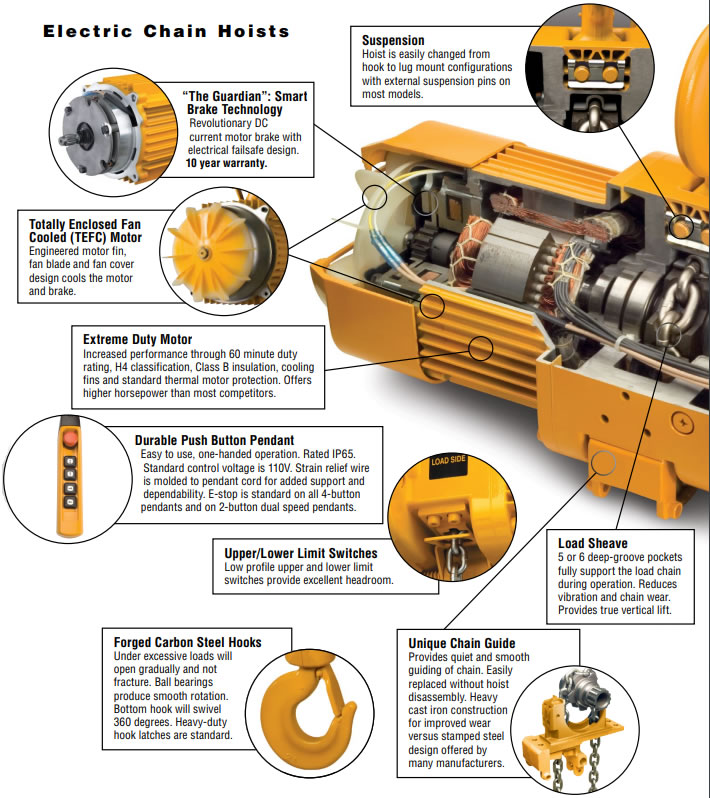

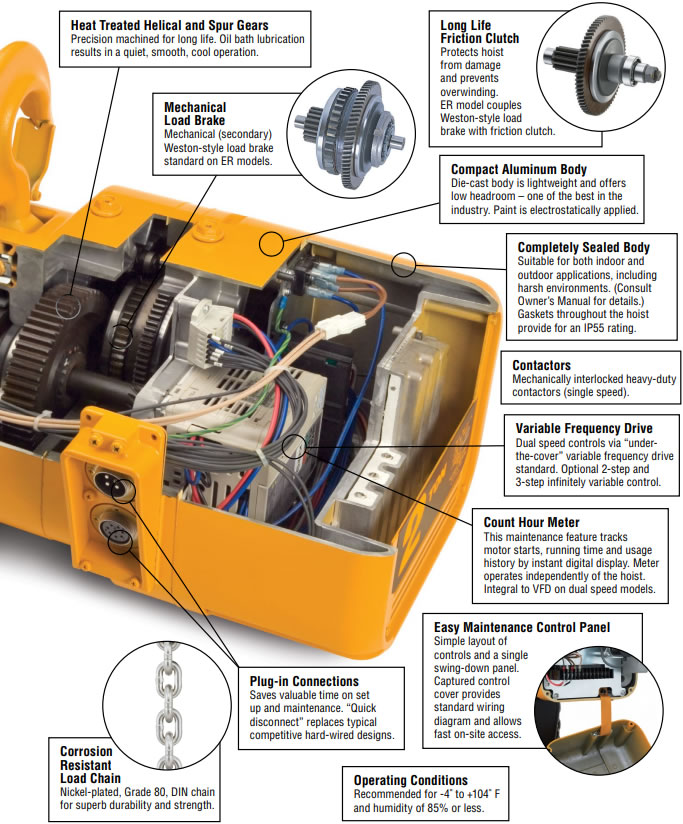

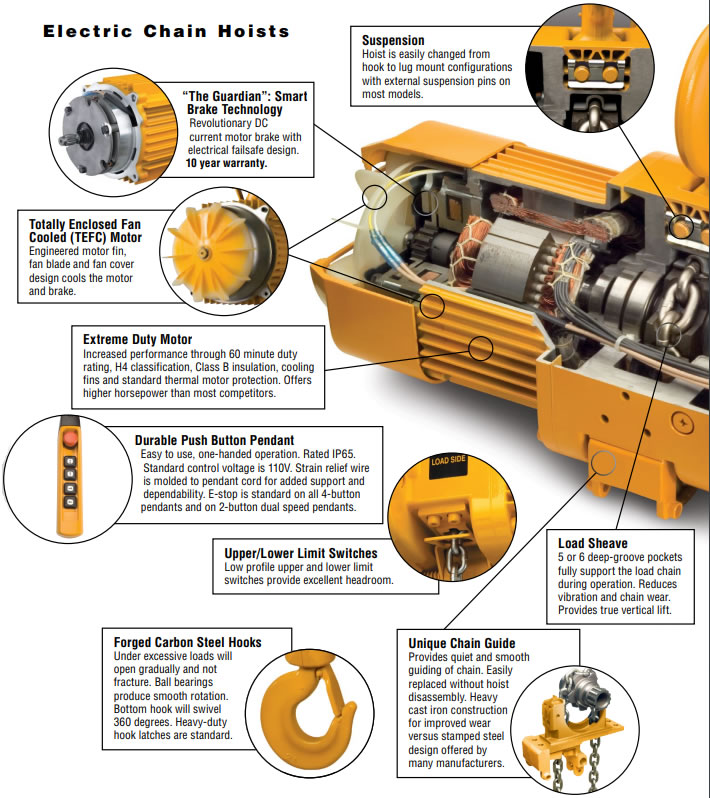

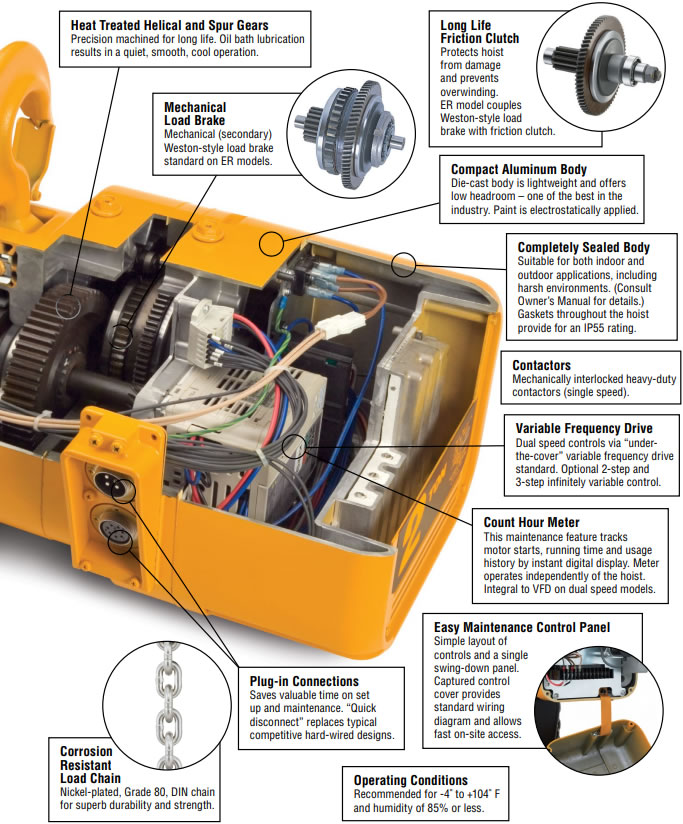

• H4 rated

hoist, 60 minute duty rating for the most

demanding applications

• “The Guardian” Smart Brake Technology revolu-

tionary DC current motor brake with electrical failsafe

design and 10 year warranty

• Adjustable dual speed via Under-thecover variable

frequency control

• Completely sealed body suitable for harsh indoor or

outdoor environments – IP55 rated (Consult owner’s

manual for details)

• High-strength, nickel-plated load chain is corrosion

and wear resistant

• 5 pocket load sheave improves chain life and promotes

smooth lifting |

|

|

|

|

|

END

TRUCKS |

|

|

|

|

|

|

|

|

•

Totally enclosed nonventilated (TENV) motors with

adjustable DC brakes

• Helical gear reducers

• Externally adjustable DC brakes allow controlled

deceleration

• Thermal motor protection

• Rubber bumpers

• Rail sweeps

• Machined steel wheels with side guide rollers that

reduce wheel friction |

|

|

|

|

|

|

|

|

|

BRIDGE

CONTROL PANEL |

|

|

|

|

|

|

|

• Field adjustable

UL listed Power Electronics®

variable frequency drive on bridge motors

• Completely pre-wired and tested

• Through-the-door fused disconnect switch

• Control transformer with primary and secondary

fusing

• Mainline contactor

• Thermal overload relay |

|

|

|

|

|

FLAT

CABLE FESTOONING |

|

|

|

|

|

|

•

Flat cable power festoon for smooth trolley

travel

• Flat cable roving pendant provides safe and

effective handling without close proximity to

the load

• Completely pre-wired and tested

• Modular design for easy packaging and installation |

|

|

|

|

|

|

RECOMMENDED

BRIDGE BEAM SIZES |

Maximum

Allowable

Span (ft) |

Capacity

(Tons) |

1 |

2 |

3 |

5 |

20 |

S10

x 25.4 |

S12

x 31.8 |

S15

x 42.9 |

S15

x 42.9

C8 x 11.5 |

25 |

S10

x 25.4 |

S12

x 31.8

C8 x 11.5 |

S15

x 42.9

C8 x 11.5 |

S15

x 42.9

C10 x 15.3 |

30 |

S12

x 31.8 |

S15

x 42.9 |

S15

x 42.9

C10 x 15.3 |

W16

x 77 |

35 |

S15

x 42.9 |

S15

x 42.9

C8 x 11.5 |

W16

x 67 |

W21

x 83 |

40 |

S15

x 42.9

C8 x 11.5 |

W18

x 60 |

W18

x 71 |

W21

x 83 |

45 |

W16

x 57 |

W18

x 71 |

W18

x 76 |

W24

x 94 |

50 |

W18

x 60 |

W18

x 76 |

W21

x 83 |

W27

x 102 |

55 |

W16

x 67 |

W21

x 83 |

W24

x 94 |

W27

x 114 |

60 |

W18

x 76 |

W21

x 93 |

W27

x 114 |

W30

x 116

C15 x 33.9 |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

PRICES

FOR TOP RUNNING - MOTORIZED* |

Cap.

(Tons) |

Model

No. |

Prices

- Standard Spans |

20

Span |

30

Span |

40

Span |

50

Span |

60

Span |

1 |

CKTR010 |

|

|

|

|

|

2 |

CKTR020 |

|

|

|

|

|

3 |

CKTR030 |

|

|

|

|

|

5 |

CKTR050 |

|

|

|

|

|

|

| *Freight

allowed in Continental USA. |

|

PRICES

FOR BOTTOM RUNNING - MOTORIZED* |

Cap.

(Tons) |

Model

No. |

Prices

- Standard Spans |

20

Span |

30

Span |

40

Span |

50

Span |

2 |

CKBR020 |

|

|

|

|

3 |

CKBR030 |

|

|

|

|

5 |

CKBR050 |

|

|

|

|

|

| *Freight

allowed in Continental USA. |

|

SPECIFICATIONS |

|

|

|

|

|

| Bridge

Beam Not Included. |

• Hoist and Trolley - Dual speed or 2-step, VFD

controlled. |

|

• End Trucks - 40 FPM or 80 FPM with VFD control

• Hoist Models - (Hoist connection is hard wired flat

cable.)

1 Ton - NERM010LD-SD

2 Ton - NERM020LD-SD

3 Ton - NERM030CD-SD

5 Ton - NERM050LD-SD |

|

• Lift - 20’ (contact Customer Service for alternate

lifts.)

• Chain Container - Canvas

• Beam Accessory Kit - Includes all braces, mounting

plates, guide wire brackets, end stops, control panel

extension brackets when applicable, hardware and

instructions.

• Bridge Control Panel - UL listed Power Elect-

ronics ® VFD Control Panel with plug and play

connections. |

|

• Crane Wiring - Complete package. Code CWE

• Flat Cable Festooning - for power

• Roving Pendant Festooning

• Pendant - 8-button with on/off

• Voltage - 460-3-60 (contact Customer Service for

alternate voltages.) |

|

|

|

|

|

|

|

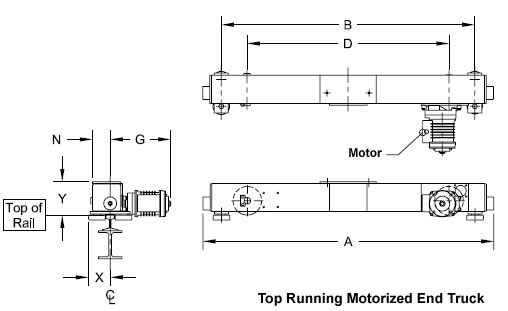

TM—Single

Girder Top Running - Motorized End Trucks |

|

|

|

|

For

heavy-duty class “C” single girder crane

applications, nothing tops our top running motorized

end trucks. |

|

|

|

|

Along

with a full range of features, end truck kits

include: two trucks; two sealed, totally enclosed,

non-ventilated (TENV) motors with adjustable

D.C. brakes; two helical gear reducers; rubber

bumpers; and bridge beam fastener set. All trucks

are fully painted. Bridge fabrication prints are also

included. As a member of Crane Manufacturers

Association of America (CMAA), we build TM

trucks to meet current industry and regulatory

codes. |

|

|

|

|

|

|

|

|

|

| Benefits

to count on: |

|

|

|

|

•

Frame fabrication from ASTM A500 structural tube

for superior strength, rigidity and compactness. |

• Gear reducer

is designed for easy field conversion

between L and S speeds. |

|

|

|

|

•

Reduced wheel friction due to heavy-duty side guide

rollers results in smooth crane travel— guide rollers

are 3 1/2” O.D. with fixed steel axles. |

• Drives

are designed for crane service, with 30 minute

rating and feature cooling fins for efficient heat

dissipation. |

|

|

|

|

•

Minimize assembly labor with fully machined frames—

girder connection, bracing and collector mounting

bracket holes are drilled and tapped for easy

installation. |

•

Externally adjustable DC brakes allow controlled

deceleration— adjustable up to 50% of rated motor

torque. |

|

|

|

| •

Thermal motor protection is standard. |

|

|

|

•

Purchase the right component for the job—dedicated

models for capacities of 1, 3, and 5 Ton, with

maximum span increments of 35' or 60'. |

|

|

•

Drives and brakes are compatible with Electronic

Acceleration Control (EAC) and Variable Frequency

Drive (VFD). |

|

|

|

•

Suitable for use on ASCE crane rail or square bar—

wheels are machined steel with flat tread and each has

2 deep groove ball bearings, meeting L10 bearing life

criteria for class C cranes. |

|

|

•

Drives are connectable for 230/460V-3-60 (including

dual speed models). Other voltages available. |

|

|

|

| •

Rail sweeps and drop stops are standard. |

|

|

|

•

Longer or shorter end truck lengths are available—

consult us. |

|

|

|

•

Sealed TENV drives with quiet, smooth–operating

helical gear reducers. |

|

|

|

|

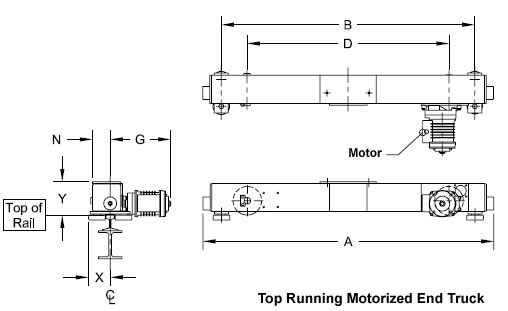

TM

— TOP RUNNING MOTORIZED END TRUCK — DIMENSIONS |

Cap.

(Tons) |

Max.

Span

(ft.) |

End Truck

Product Code |

Wheel

Dia.

(in) |

Sug.

Min.

Runway

Rail

(ASCE#) |

A

Overall

Length

(in) |

B

Roller

Base

(in) |

D

Wheel

Base

(in) |

N

Runway

Ctr. Line

to Outer

Edge of

ET (in) |

X*

Width

Beyond

Span (in) |

Y

Top of Rail

to Top of

End Truck (in) |

G

Motor

(in) |

| 1 |

35 |

TMD-3-0135 |

3.74 |

30 |

61 |

53 |

43 |

2.1 |

4.6 |

7.1 |

12.7 (L/S)

13.1 (H)

14.0 (D) |

| 60 |

TMD-3-0160 |

98 |

90 |

80 |

| 3 |

35 |

TMD-3-0335 |

6.10 |

62 |

54 |

43 |

3.8 |

13.0 (L/S)

13.4 (H)

14.3 (D) |

| 60 |

TMD-3-0360 |

99 |

91 |

80 |

| 5 |

35 |

TMD-3-0535 |

40 |

62 |

54 |

43 |

4.7 |

9.2 |

| 60 |

TMD-3-0560 |

8.27 |

99 |

90 |

74 |

3.5 |

9.3 |

15.0 (L/S/D)

15.4 (H) |

|

| *Based

on suggested minimum runway rail. |

|

|

|

|

|

|

|

|

TM

— TOP RUNNING MOTORIZED END TRUCK — SPECIFICATIONS |

End Truck

Product Code |

Speed

Code D |

End

Truck

Weight

(lbs/pr) |

One

Motor Per End Truck

3 Phase 60 Hz |

Output

(Hp) |

Rated

Current

(amps ea.) |

| @230V |

@460V |

| TMD-3-0135 |

0.33/0.08 |

1.6/1.1 |

0.9/0.8 |

325 |

| TMD-3-0160 |

422 |

| TMD-3-0335 |

421 |

| TMD-3-0360 |

538 |

| TMD-3-0535 |

512 |

| TMD-3-0560 |

0.5/0.13 |

2.0/1.5 |

1.2/0.9 |

739 |

|

| Speed

Code: D - Designates dual speed 80/20 ft/min |

|

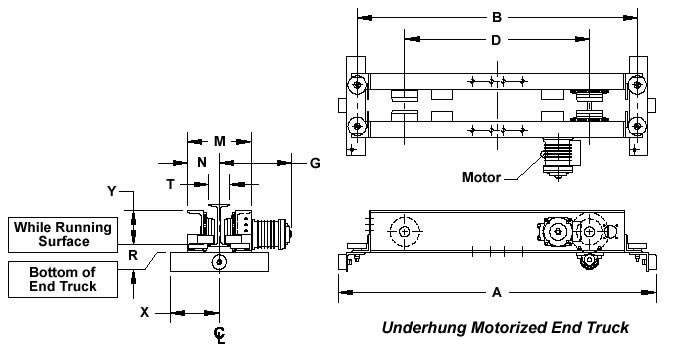

UM

- SINGLE GIRDER UNDERHUNG MOTORIZED END TRUCKS |

|

For

heavy-duty class “C” single girder crane applications, our underhung

motorized

end trucks combine superior performance with underhung space savings. |

|

Along

with a full range of features, end truck kits include: two trucks; two sealed,

totally

enclosed, non-ventilated (TENV) motors with adjustable DC brakes; two helical

gear

reducers; rubber bumpers; and bridge beam fastener set. All trucks are fully

painted. Bridge

fabrication prints are also included. As a member of the Crane Manufacturers

Association

of America (CMAA), we build UM trucks to meet current industry and regulatory

codes. |

|

|

|

|

| Benefits

to count on: |

|

|

|

|

|

|

•

Frames fabricated from MC channel

provide superior strength, rigidity and

structural integrity. |

|

|

|

|

•

Reduced wheel friction due to heavy-duty

side guide rollers results in smooth crane

travel—guide rollers are 3 1/2” O.D. with

fixed steel axles. |

|

|

|

|

•

Dual tread wheels for use on S or W shaped

runway beams—each wheel fitted with 2

deep groove ball bearings, meeting L10

bearing life criteria for class C cranes. |

|

|

|

|

•

Runway flange widths up to 6” standard,

with wider ranges also available

(trucks for patented track available). |

|

|

|

|

•

Minimize assembly labor with fully machined frames—girder connection,

bracing and collector mounting bracket

holes are pre-drilled for easy installation. |

|

•

Purchase the right component for the job—dedicated models for capacities

of 2, 3, and 5 Ton, with maximum

span increments of 35' or 50'. |

|

| •

Sealed TENV drives with quiet, smooth–operating helical gear reducers. |

|

| •

Gear reducer is designed for easy field conversion between L and S speeds. |

|

| •

Drives are designed for crane service, with 30 minute rating and feature

cooling fins for efficient heat dissipation. |

|

| •

Thermal motor protection is standard. |

|

| •

Externally adjustable DC brakes allow controlled deceleration—adjustable

up to 50% of rated motor torque. |

|

•

Drives and brakes are compatible with Electronic Acceleration Control (EAC)

and Variable Frequency Drive

(VFD). |

|

| •

Drives are connectable for 230/460V-3-60 (including dual speed models).

Other voltages available. |

|

| •

Rail sweeps and drop stops are standard. |

|

| •

Longer or shorter end truck lengths are available — consult us. |

|

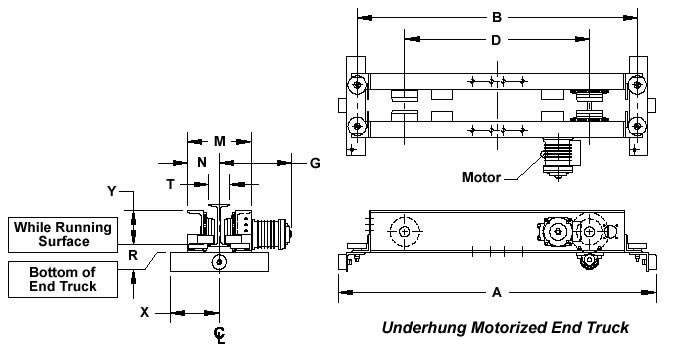

UM

- UNDERHUNG MOTORIZED END TRUCK - DIMENSIONS |

Cap.

(Tons) |

Max.

Span

(ft.) |

End Truck

Product Code |

Wheel

Dia. (in) |

T

Flange

Range

Std. (in) |

A

Overall

Length

(in) |

B

Roller

Base

(in) |

D

Wheel

Base

(in) |

M

End

Truck

Frame

Width (in) |

N

Runway

Ctr. Line to

Outer Edge

of ET (in) |

R

Wheel

Running

Surf. To

Bottom of

Truck (in) |

X*

Width

Beyond

Span

(in) |

Y Wheel

Running

Surface to

Upper Most

Part of ET

(in) |

G

Motor

(in) |

| 2 |

35 |

UMD-3-0235 |

4.33 |

3 - 6 |

60 |

53 |

39 |

T+8.1 |

M/2 |

1.5 |

11.3

-

T/2 |

6.5 |

T/2+

11.9

12.3 (H)

13.3 (D) |

| 50 |

UMD-3-0250 |

82 |

75 |

61 |

| 3 |

35 |

UMD-3-0335 |

4.92 |

60 |

53 |

35 |

T+8.2 |

| 50 |

UMD-3-0350 |

82 |

75 |

57 |

| 5 |

35 |

UMD-3-05355 |

5.51 |

4 - 6 |

60 |

53 |

33 |

T+9.8 |

1.6 |

6.8 |

T/2+

13.7 (L/S/D) 14.2 (H) |

| 50 |

UMD-3-0550 |

82 |

75 |

55 |

|

| *These

formulas for Width Beyond Span do not apply for flanges greater than 6 inches.

For flanges greater then 6 inches, consult us. |

|

|

|

|

| UNDERHUNG

MOTORIZED END TRUCK |

|

|

|

|

UM

- UNDERHUNG MOTORIZED END TRUCK - SPECIFICATIONS |

End Truck

Product Code |

Speed

Codes D |

End

Truck

Weight

(lbs/pr) |

One

Motor Per End Truck

3 Phase 60 Hz. |

Output

(Hp) |

Rated

Current

(amps ea.) |

| @230V |

@460V |

| UMD-3-0235 |

0.33/0.08 |

1.6/1.1 |

0.9/0.8 |

522 |

| UMD-3-0250 |

659 |

| UMD-3-0335 |

543 |

| UMD-3-0350 |

680 |

| UMD-3-0535 |

0.5/0.13 |

2.0/1.5 |

1.2/0.9 |

638 |

| UMD-3-0550 |

795 |

|

| Speed

Code: D - Designates dual speed 80/20 ft/min |

|

NERM ELECTRIC CHAIN HOISTS WITH

MOTORIZED TROLLEYS |

|

|

|

|

|

|

|

|

|

|

|

|

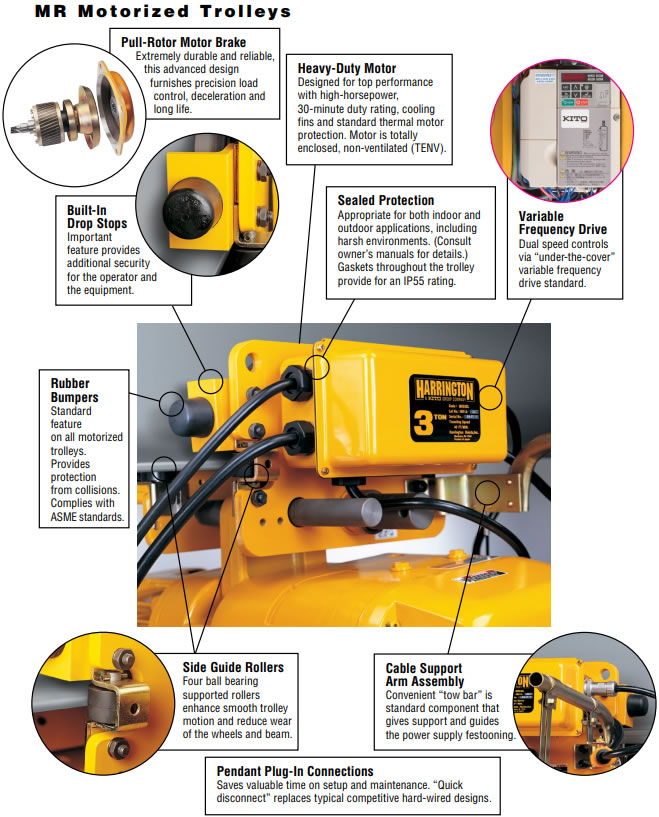

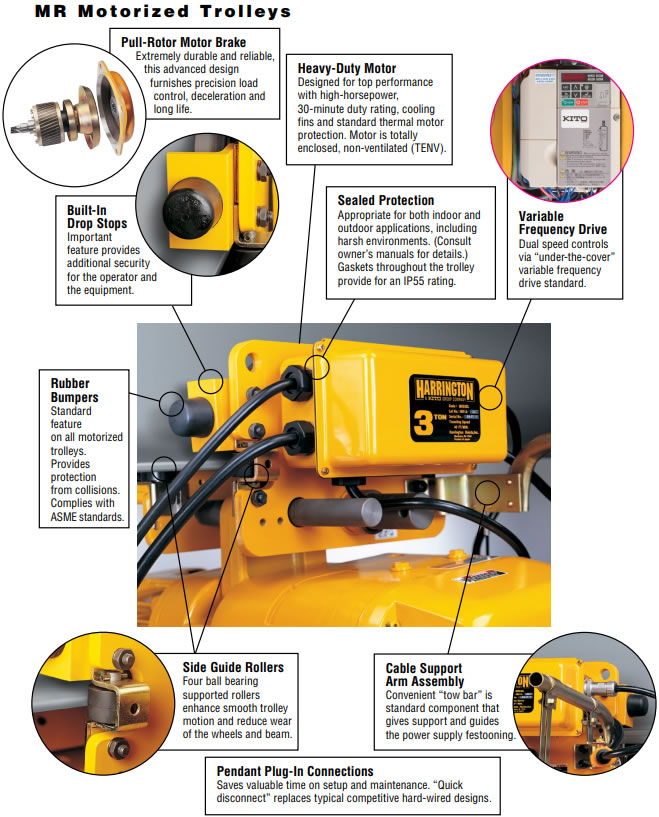

The

MR Series of electric trolleys further expand the capabilities of our NER

line of electric

hoists. These trolleys feature an innovative side guide roller system that

results in very

smooth travel along the beam. |

|

|

|

|

|

|

|

|

|

|

|

|

| STANDARD

MOTORIZED TROLLEY SPECIFCATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

| • Capacity Range |

|

• Standard Pendants |

|

|

|

1/8

Ton – 5 Ton |

|

|

|

|

4-button

(momentary contacts) with

emergency on/off (maintained

contacts) |

|

|

|

|

|

|

|

|

|

|

|

|

| • Standard Voltage |

|

|

|

|

|

|

|

208-230/460-3-60

Optional voltages available Dual speed

models are not reconnectable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Shafts |

|

|

|

|

|

|

|

|

Standard

shafts fit wide flange range

Longer shafts for wider beams

Spacers for easy adjustments |

|

|

|

|

|

|

|

|

|

|

|

|

| • Control Voltage |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

110V

(optional 24V) |

|

|

|

|

|

|

|

|

|

|

|

|

• Drop Stops |

|

|

|

|

|

|

|

|

|

|

|

| • Duty Cycle* |

|

|

|

|

|

|

|

|

|

Standard |

|

|

|

|

|

|

|

|

|

|

Single

Speed – 30 Min.

Dual Speed – 30/10 Min. with VFD |

|

|

|

|

|

|

|

|

|

|

|

|

• Bumpers |

|

|

|

|

|

|

|

|

Standard |

|

|

|

|

|

|

|

|

|

|

|

|

| • Classification* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Wheels |

|

|

ASME

H4

ISO M5 or M4

FEM 2M or 1Am |

|

|

|

|

|

|

|

|

|

All

steel

Shielded ball bearings

Fit flat or tapered beam flange |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| • Ratings |

|

|

|

|

|

|

|

|

|

|

|

• Standard Power

Supply Length |

|

|

|

Trolley

– IP55

Pendant – IP65 |

|

|

|

|

|

|

|

|

|

|

|

30' (longer

lengths available) |

|

|

|

|

|

|

|

|

|

|

|

|

• Standard

Pendant Drop |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4'

less than lift (longer drops available) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

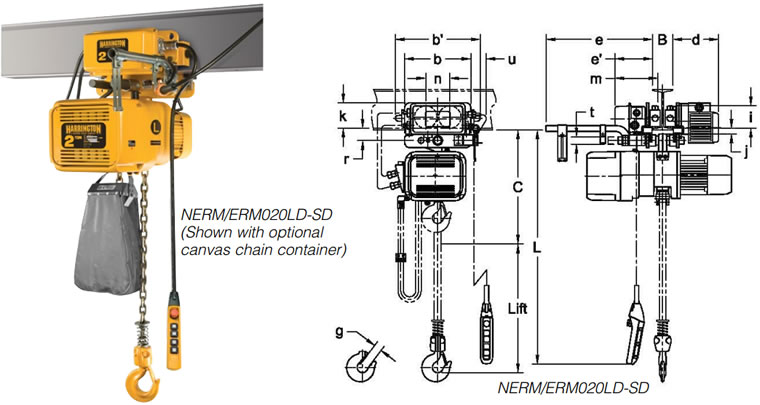

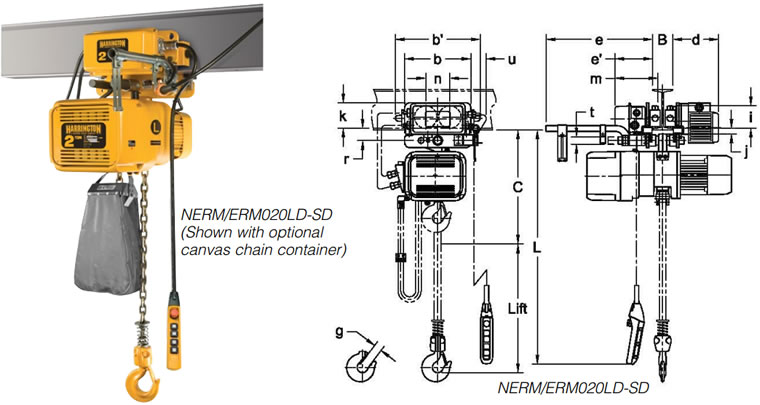

NERM/020L-L/S

(Shown with

optional canvas chain container) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| FEATURES

AND BENEFITS |

|

|

|

|

|

|

| • Easy Access Suspension |

|

• Limit Switches |

|

External pins

allow for quick change from hook to

lug for trolley mount configurations on most models. |

|

|

Low-profile

upper and lower limit switches are

standard. |

|

|

|

|

|

|

| • Perpendicular Orientation |

|

|

|

|

|

• Contactors |

|

MR

motorized trolley mount hoists are configured as

perpendicular to the beam. Parallel mount is

available as an option. |

|

|

|

|

Mechanically

interlocked, heavy-duty contactors on

single speed models. |

|

|

|

|

|

|

|

• Friction Clutch and Load Brake |

|

|

|

| • Green Initiative |

|

|

Friction

clutch is standard on NER. Carbon friction

material provides consistent performance over a wide

temperature range. |

|

Built smarter

without the use of harmful materials. Environmentally friendly. RoHS compliant. |

|

|

|

|

|

|

|

|

| • Notched Hook and Latch System |

|

•

High Strength, Corrosion and Wear Resistant

Load Chain |

|

Provides

positive closing and improves resistance

against lateral forces. |

|

|

|

|

Grade

80, super strength, nickel-plated load chain,

certified to DIN standards, uses unique technology to

greatly increase resistance to fatigue and wear |

|

|

|

|

| • High Air Flow |

|

|

|

Cooler

motor and brake attributed to an engineered

motor fin, fan blade and fan cover design. |

|

|

|

|

|

|

|

|

|

• Standard Count Hour

Meter |

|

|

|

|

Records

and displays the number of lowering starts

and hoist on time which is valuable for preventive

maintenance. Integral to VFD on dual speed models. |

| • Unique Load Sheave |

|

|

|

Increased

number of pockets reduce chain vibration and

increase chain life. 5 pockets standard; 6 pockets on

smaller body hoists. |

|

|

|

|

|

|

|

|

|

• Dual Speed VFD |

|

|

|

Under-the-cover

VFD standard for dual speed hoists

and trolleys. Hoist speed ratio is 6:1 with adjustability

up to 12:1. Trolley speed ratio is 6:1 with adjustability

up to 10:1 |

|

|

|

|

| • Extended Chain Life |

|

|

|

Decreased chain

wear as a result of a revolutionary heat

treatment process, improved material and chain size. |

|

|

|

|

|

|

| • Pendant Controls |

|

|

|

|

|

• “The Guardian”:

Smart Brake Technology |

|

Ergonomic

design for operator comfort. Red button

emergency stop is standard on all 4-button dual speed

pendants. |

|

|

|

|

|

A

current driven electromagnetic brake does not

release unless the motor is energized. 10 year hoist

brake warranty. |

|

|

|

|

|

|

|

|

|

|

|

|

NERM

SERIES - Motorized Trolleys FEATURES AND BENEFITS |

|

|

|

|

|

|

|

|

|

|

| DUAL

SPEED HOIST WITH DUAL SPEED TROLLEY - SPECIFICATIONS |

Cap.

(Tons) |

Product

Code |

Std.

Lift

(ft) |

Push

Button

Cord L

(ft) |

Lifting

Speed

(ft/min)

|

Traversing

Speed

(ft./min) |

Lifting

Motor‡

3 Phase 60 Hz |

Traversing

Motor‡

3 Phase 60 Hz |

Flange

Width

Adjustability B (in) |

Min.

Allow.

Radius for

Curve

(in) |

Load

Chain

Dia.

(mm)

x

Chain

Fall

Lines |

Net

Wgt.

(lbs) |

Wgt.

Addl.

One

Foot

of

Lift

(lbs.) |

Output

(Hp) |

Rated

Current

(amps) |

Output

(Hp) |

Rated

Current

(amps) |

Std. |

Optional |

@208 -

230V |

@460V |

@208 -

230V |

@460V |

| 1 |

(N)ERM010LD-SD |

20 |

16 |

14/2.5 |

80/13 |

1.2 |

5.1 |

2.7 |

0.54 |

3.4 |

1.7 |

2.28

to

5.00 |

5.01

to 6.02

OR

6.03 to

12.00 |

31.5** |

7.7 x 1 |

170 |

0.89 |

| 2 |

(N)ERM020LD-SD |

2.4 |

9.1 |

4.5 |

0.54 |

3.4 |

1.7 |

3.23

to

6.02 |

6.03 to

7.02 OR

7.03 to

12.00 |

31.5† |

10.2 x 1 |

247 |

1.6 |

| 3 |

(N)ERM030CD-SD |

17/3 |

4.7 |

17.3 |

8.3 |

0.54 |

3.4 |

1.7 |

39.4 |

10.2

x 2 |

340 |

3.2 |

| 5 |

(N)ERM050LD-SD |

11/2 |

1.0 |

5.4 |

2.7 |

3.94

to

7.01 |

7.02 to

7.60 OR

7.61 to

12.00 |

70.9 |

11.2 x 2 |

439 |

3.8 |

|

‡Although

both 208/230 & 460 Volts are shown together, the motors are NOT reconnectable.

Hoist speed ratio is 6:1 with adjustability up to 12:1.

Trolley speed ratio is 6:1 with adjustability up to 10:1. |

|

DUAL

SPEED HOIST WITH DUAL SPEED TROLLEY — DIMENSIONS |

Cap.

(Tons) |

Product

Code |

Headroom

C (in) |

b

(in) |

b'

(in) |

d

(in) |

e

(in) |

e'

(in) |

g

(in) |

i

(in) |

j

(in) |

k

(in) |

m

(in) |

n

(in) |

r

(in) |

t

(in) |

u

(in) |

| 1 |

(N)ERM010LD-SD |

17.1 |

12.4 |

15.6 |

8.7 |

20.3 |

7.1 |

1.2 |

3.74 |

0.9 |

5.1 |

8.1 |

4.3 |

2.0 |

1.22 |

3.3 |

| 2 |

(N)ERM020LD-SD |

22.4 |

12.8 |

16.4 |

8.8 |

20.5 |

7.3 |

1.6 |

4.33 |

1.1 |

4.9 |

8.3 |

4.6 |

2.4 |

1.42 |

3.0 |

| 3 |

(N)ERM030CD-SD |

32.9 |

13.4 |

17.4 |

8.9 |

20.5 |

7.3 |

1.8 |

4.92 |

1.1 |

5.2 |

8.5 |

5.2 |

2.7 |

1.69 |

2.8 |

| 5 |

(N)ERM050LD-SD |

33.1 |

15.7 |

19.8 |

11.1 |

20.8 |

7.6 |

1.9 |

5.51 |

1.7 |

5.7 |

9.2 |

5.9 |

3.4 |

2.13 |

2.2 |

|

Hoist

speed ratio is 6:1 with adjustability up to 12:1.

Trolley speed ratio is 6:1 with adjustability up to 10:1. |

|

Plug and Play Crane Kit Package,

Harrington NERM Dual Speed Hoist, End Trucks, Top Running End Trucks,

Underhung End

Trucks, Flat Cable Festooning, Single Girder Top Running Motorized End

Trucks, Single Girder Underhung Motorized End

Trucks, Electric Chain Hoists with Motorized Trolley, Electric Chain Hoists,

Motorized Trolleys, and Dual Speed Models from

your source for material handling equipment. |

Back

to Product Category |

|

|